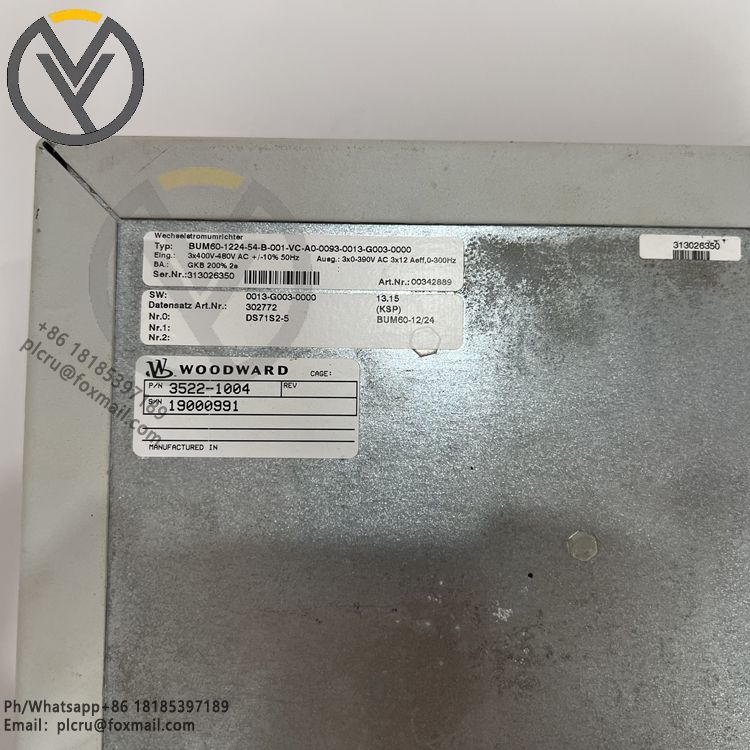

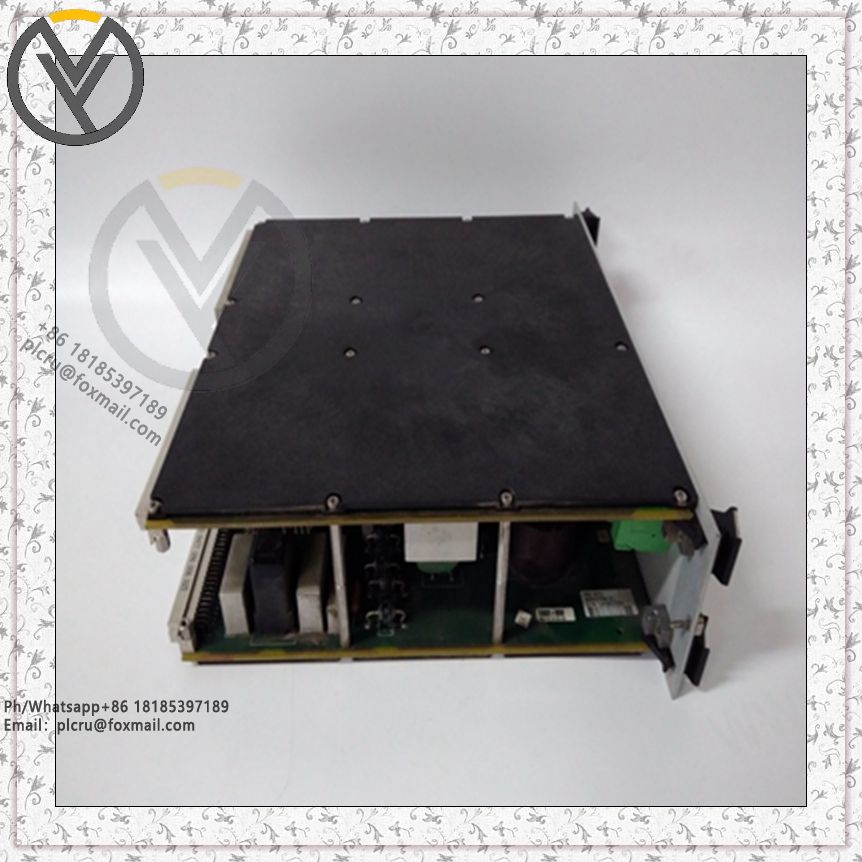

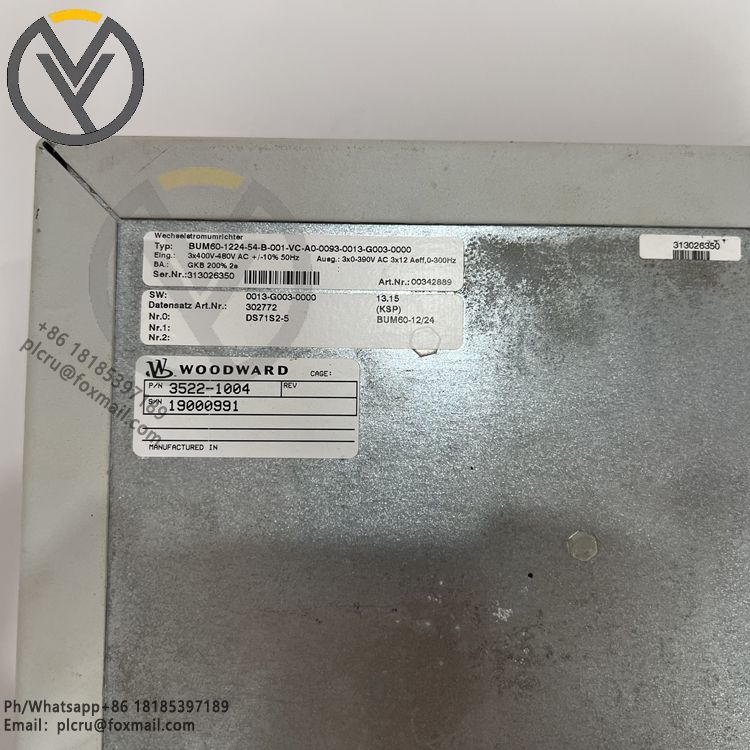

Woodward 3522-1004 EM-Driver EM-80/EM-300 Actuator

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

Woodward 3522-1004 EM-Driver is a driver module designed for EM-80 and EM-300 se

Woodward 3522-1004 EM-Driver is a driver module designed for EM-80 and EM-300 series actuators. It is an important product of Woodward in the field of industrial control. It is mainly used to accurately control the action of the actuator and is widely used in the speed regulation and control of power equipment such as engines, steam turbines, and gas turbines. The following is a detailed introduction:

Core functions and roles

Drive and control actuator: As the core driving component of the EM-80/EM-300 actuator, it receives electrical signals (usually 4-20mA current signals or 0-10V voltage signals) from the controller (such as PLC, DCS or special speed regulator) and converts them into mechanical action instructions of the actuator, controls the displacement or angle of the actuator, and then adjusts the key parameters such as the fuel volume and valve opening of the engine to achieve precise control of the speed and power of the equipment.

Signal processing and feedback: Built-in signal conditioning circuit can filter, amplify and linearize the input signal, and receive the position feedback signal of the actuator (such as potentiometer feedback or Hall sensor signal) to form a closed-loop control to ensure the accuracy and stability of the actuator action.

Protection function: It has safety mechanisms such as overcurrent protection, overheating protection, and overload protection. When the actuator is stuck, the power supply is abnormal, or the load is too large, it can automatically cut off the drive signal or trigger an alarm to prevent equipment damage.

Adaptive actuator characteristics (EM-80/EM-300 series)

EM-80: Miniaturized actuator with small output force (usually tens to hundreds of Newtons) and fast response speed, suitable for small-power engines or precision adjustment scenarios (such as small generator sets, industrial furnace fuel control).

EM-300: Medium and large actuators with greater output force (up to thousands of Newtons) and strong load capacity, suitable for fuel or gas regulation of high-power power equipment (such as gas turbines and large diesel engines).

Technical parameters (refer to typical specifications, the specific details are subject to the manual)

Input signal: standard control signal 4-20mA (current type) or 0-10V (voltage type), input impedance is usually 250Ω (current input) or 10kΩ (voltage input).

Power supply requirements: DC power supply, common specifications are 24VDC (±10%), some models support 12VDC or 48VDC, power consumption depends on the actuator model, generally 5-20W.

Output drive: Provide drive current for the actuator, the maximum output current is usually 1-5A (matched according to the actuator model).

Feedback signal: Support position feedback signal output, such as 1-5V or 4-20mA, for closed-loop control loop.

Working environment: The working temperature range is -40℃ to +70℃, and the protection level is generally IP54 (dustproof and splashproof), which can adapt to the harsh environment of industrial sites.

Response time: The time from receiving the control signal to the actuator reaching the target position is usually tens of milliseconds to hundreds of milliseconds (depending on the actuator model).

Application areas

Power equipment control: Fuel/gas regulation systems of diesel engines, gas turbines, and steam turbines to ensure that the equipment operates stably at the set speed or power.

Energy industry: Speed regulation of units in thermal power plants and natural gas power plants, fuel control of biomass energy and waste incineration power generation equipment.

Industrial drive: Speed regulation of large compressors and pump equipment to ensure stable operation of the production process.

Ships and locomotives: Speed regulation systems of ship main engines and diesel locomotive engines to ensure the reliability of power output.

Advantages and characteristics

High-precision control: Through closed-loop feedback design, the control accuracy can reach ±0.5% of the full scale, meeting the strict requirements of power equipment for regulation accuracy.

High reliability: Adopting industrial-grade components, it has excellent anti-vibration and anti-electromagnetic interference (EMC) performance, and is suitable for high temperature, high humidity, and dusty field environments.

Strong compatibility: supports a variety of standard control signals and feedback types, and can be seamlessly connected with Woodward's own speed regulators (such as 2301A, 505E) or third-party control systems.

Easy installation and maintenance: modular design, clear wiring terminals, easy on-site installation and replacement; some models are equipped with LED indicators, which can intuitively display the working status (such as power supply, fault alarm), simplifying troubleshooting.