Woodward 723 Plus Digital Control 9906-619 8280-339

The Woodward 723 Plus Digital Control 9906 - 619/8280 - 339 is a high - performance digital control system designed for a variety of industrial applications. Here is a detailed introduction:

Model Overview

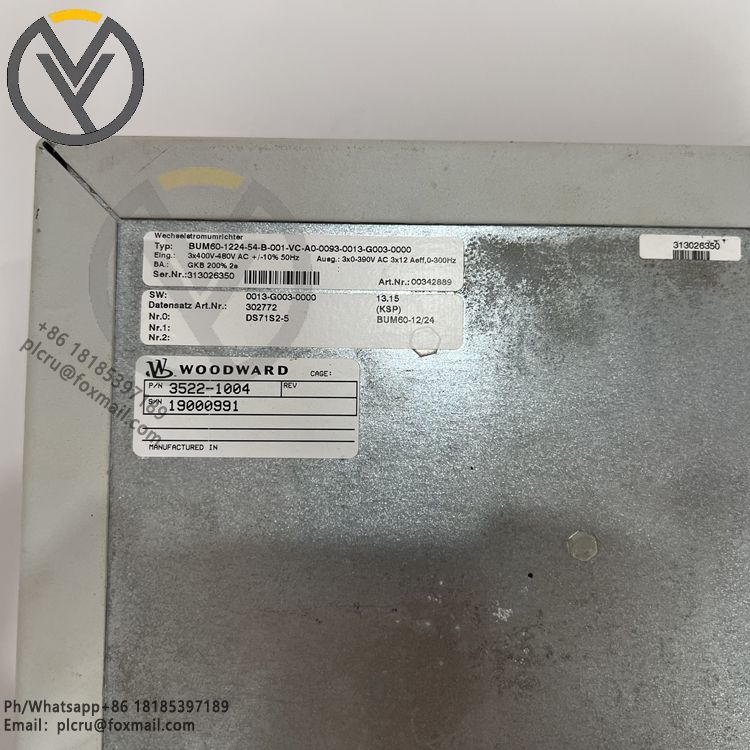

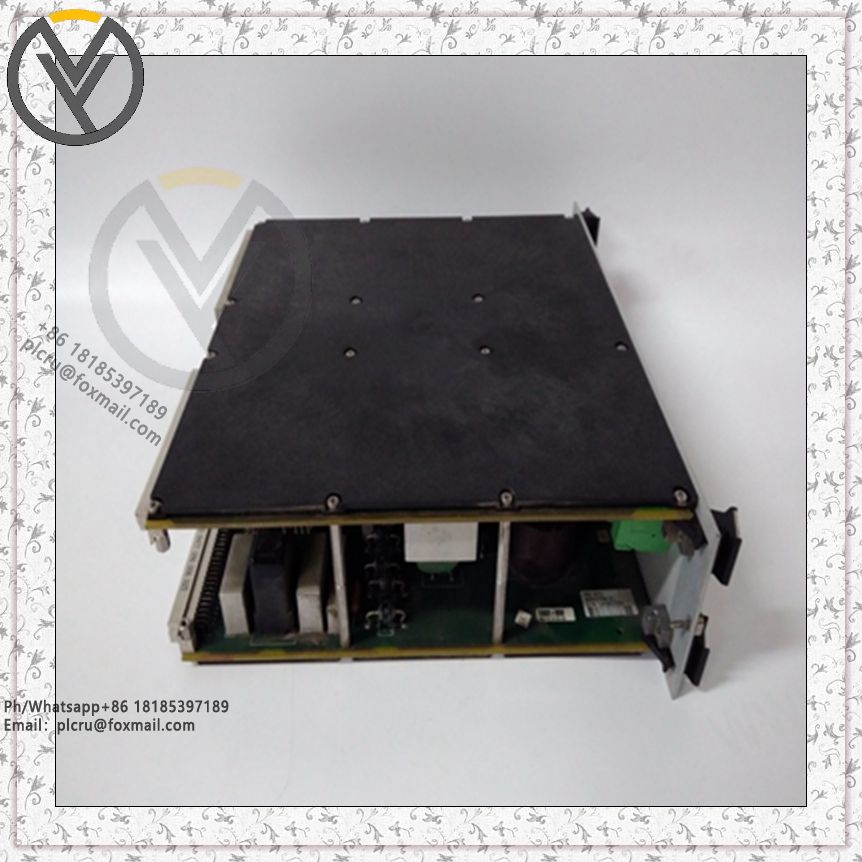

- 9906 - 619: It is the hardware model of the Woodward 723 Plus Digital Control. It is a low - voltage model with an input voltage of 18 - 40 VDC. It is designed to work with magnetic pickups (MPUs) or proximity switches and is equipped with a rack position sensor for mechanical load - sharing functions. This model comes in a sheet - metal chassis with three 9 - pin subminiature D connectors and three terminal strips for connections.

- 8280 - 339: It is a programmable digital controller in the 723 Plus series. It has two speed - sensing methods, suitable for applications requiring MPUs or proximity switches. It has four analog inputs, three analog outputs, eight discrete inputs, and three discrete outputs. The analog I/O has an accuracy rating of 0.5% of full scale, and the load - sharing input has an accuracy of 1.0% of full scale.

Features

- Precise control capabilities: It adopts advanced digital control algorithms to precisely regulate process variables such as speed, temperature, and pressure. It can quickly and accurately adjust the controlled object to the set value and maintain stability with low overshoot and fast response speed.

- Rich interface configuration: It is equipped with various analog and digital input and output interfaces to connect to sensors, actuators, and other devices1. It also supports multiple industrial communication protocols such as Modbus and RS - 485, enabling seamless integration with upper - level control systems, programmable logic controllers (PLCs), and human - machine interfaces (HMIs) for remote monitoring, parameter setting, and program upgrades.

- High - reliability design: It uses high - quality electronic components and advanced manufacturing processes to enhance its anti - interference ability, enabling it to operate stably in harsh industrial environments4. It is also equipped with various protection functions such as over - current protection, over - voltage protection, and over - temperature protection to ensure the safety and stability of the device and the controlled equipment.

- Programmable and configurable: It usually has a user - friendly programming and configuration interface, allowing users to customize control strategies and parameters according to specific application requirements6. Through programming software, users can set up control algorithms, input - output logic, and alarm conditions.

Applications

- Power generation industry: It can be used to control the speed and load of generators to ensure the stable output of voltage and frequency. In addition, it can participate in the automatic synchronization process of generators, improving the reliability and efficiency of power generation systems.

- Industrial process control: It is widely used in various industrial processes such as chemical production, petroleum refining, and metallurgy. It can control the temperature, pressure, and flow of process media to ensure the stability and quality of production processes.

- Motor control: It can be used to control the speed and torque of motors, achieving energy - saving operation and precise positioning of motors. In industrial automation production lines, it is often used to control conveyor belts, motors of machine tools, and robotic arms to improve production efficiency and product quality.

- Marine applications: It is suitable for controlling reciprocating engines used in marine propulsion, managing and controlling engine speed and load to ensure the reliable operation of ships in different navigation conditions.