Woodward 8237-1367 ProTech-GII Panel Mount Protection

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

Woodward 8237 - 1367 ProTech - GII Panel Mount Protection is a configurable over

Woodward 8237 - 1367 ProTech - GII Panel Mount Protection is a configurable overspeed detection system, mainly used to protect various types of steam, gas and water turbines. Here is a detailed introduction:

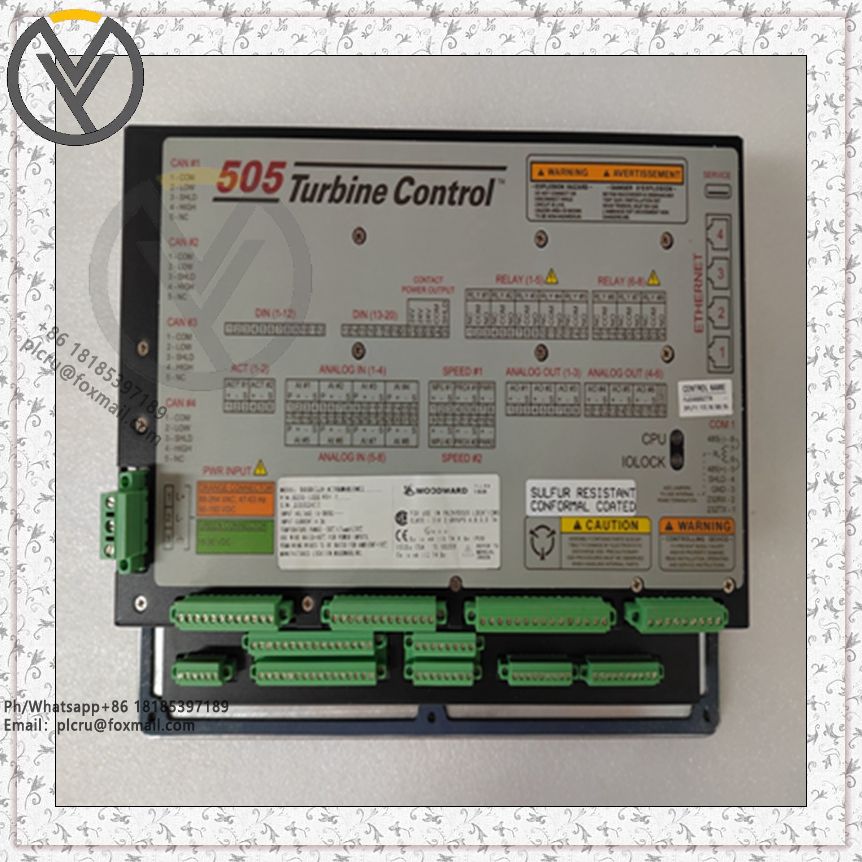

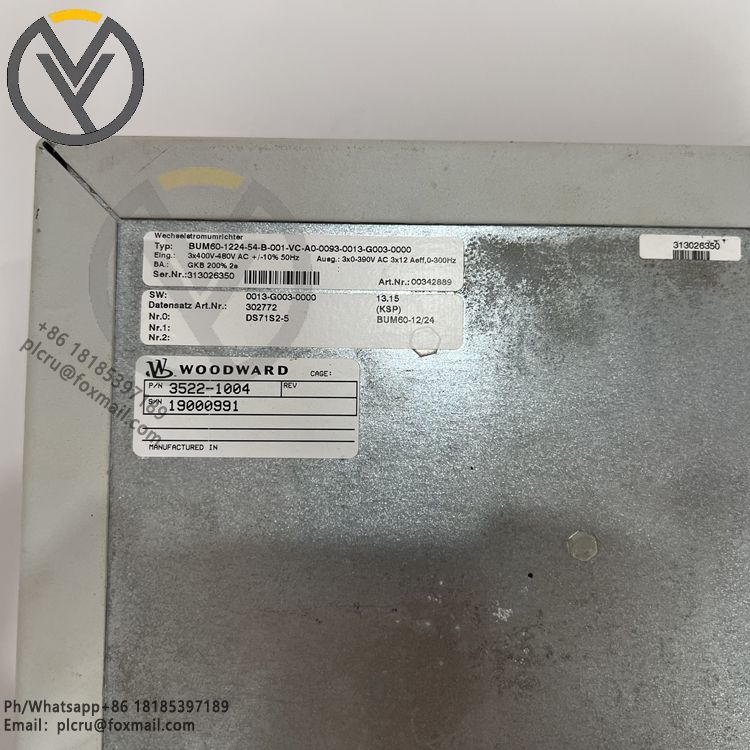

Technical parameters

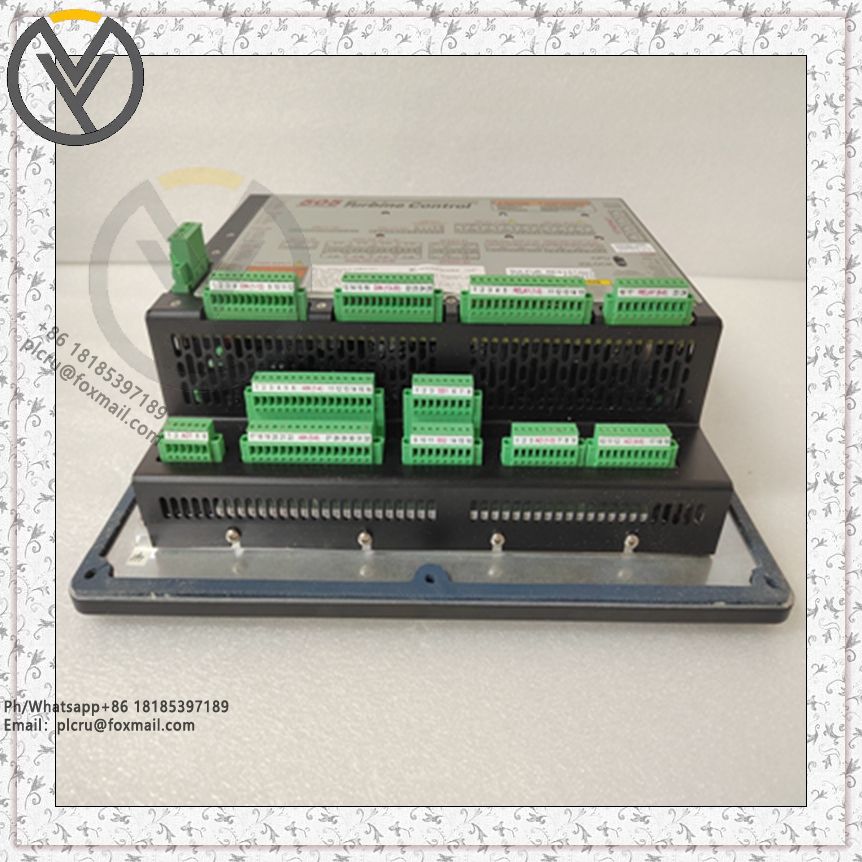

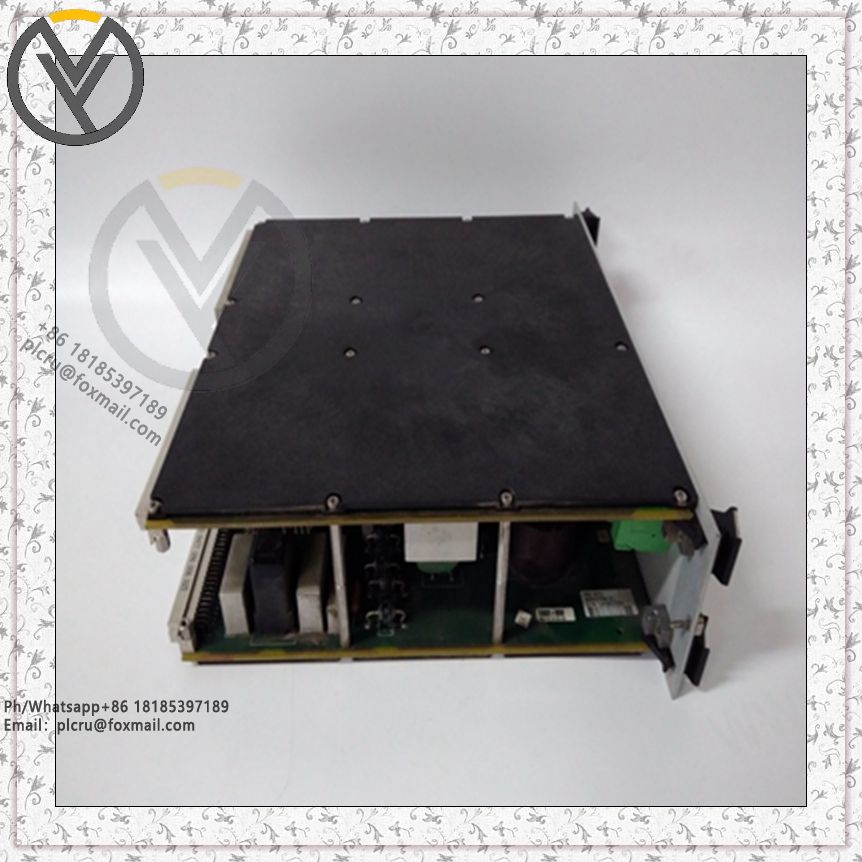

Dimensions: 330mm×445mm×159mm.

Protection level: IP56.

High voltage input: 90 - 264V AC/47 - 63Hz or 100 - 150V DC, 30W per module.

Low voltage input: 18 - 32V DC, 30W per module.

Operating temperature: -20℃ to + 60℃ (-4℉ to + 140℉).

Storage temperature: -20℃ to + 65℃ (-4℉ to + 158℉).

Weight: Approximately 22 pounds.

Features

Overspeed protection: By monitoring the speed of the turbine, when an overspeed or over-acceleration event is detected, a signal can be quickly issued to safely shut down the turbine to prevent equipment damage or even safety accidents caused by overspeed.

Multiple output configurations: Two dual redundant trip relay outputs are provided, using a three-out-of-two voting architecture; three independent non-voting trip relay outputs can also be selected, with independent alarm relays, 4-20mA speed readings and Modbus communication functions, which are easy to integrate into various turbine safety systems.

Test function: Each module can be tested manually through the front panel, Modbus communication port, or automatically through the automatic test program function. Users can also configure regular automatic overspeed tests, testing one module at a time, and recording the test results. If an error is detected, the test is suspended.

Event recording: The log function can record all trips, alarms, quick closing valve response times and overspeed events. Use a rolling buffer to record the last 50 trip or alarm events and the last 20 overspeed events in memory. Each module uses non-volatile memory to ensure that the recorded events can also be saved when the power is off.

Real-time clock: Each module is equipped with a real-time clock to ensure accurate time recording, and a special time averaging function is used to synchronize the clocks between modules.

Application scenarios

Turbine protection: Applicable to steam, gas and water turbines of all sizes, whether small turbines in industrial production or large power generation turbines in the power industry, it can provide reliable overspeed protection.

Other rotating equipment protection: It can also be applied to rotating equipment such as reciprocating engines to prevent overspeed and ensure the safe operation of the equipment.