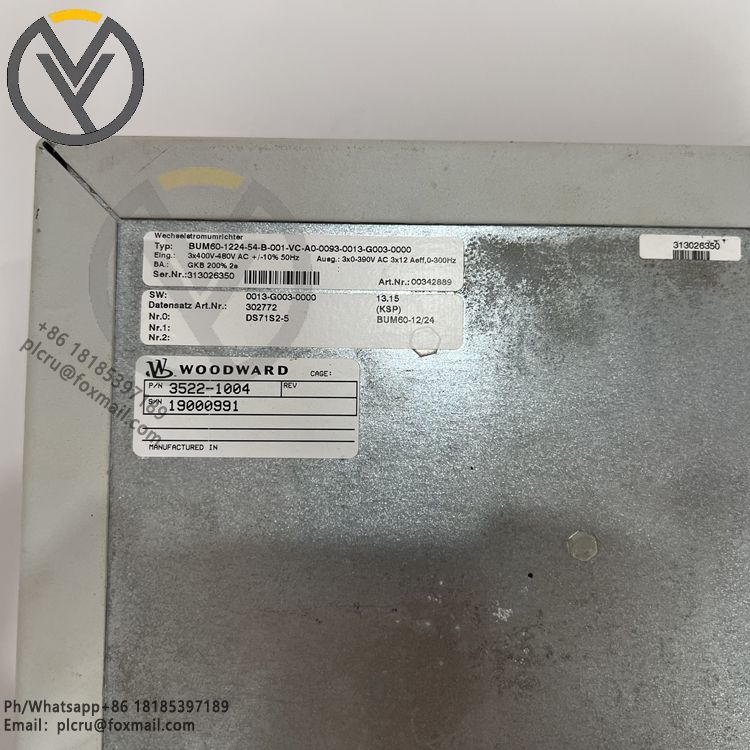

WOODWARD 5501-432 Actuator Control Module

The WOODWARD 5501 - 432 Actuator Control Module is a key device in industrial control systems, mainly used to control actuators. Here is a detailed introduction:

- Model: 5501 - 432

- Manufacturer: WOODWARD, a world - renowned company in the field of industrial control, with advanced technology and rich experience, dedicated to providing high - quality control products and solutions.

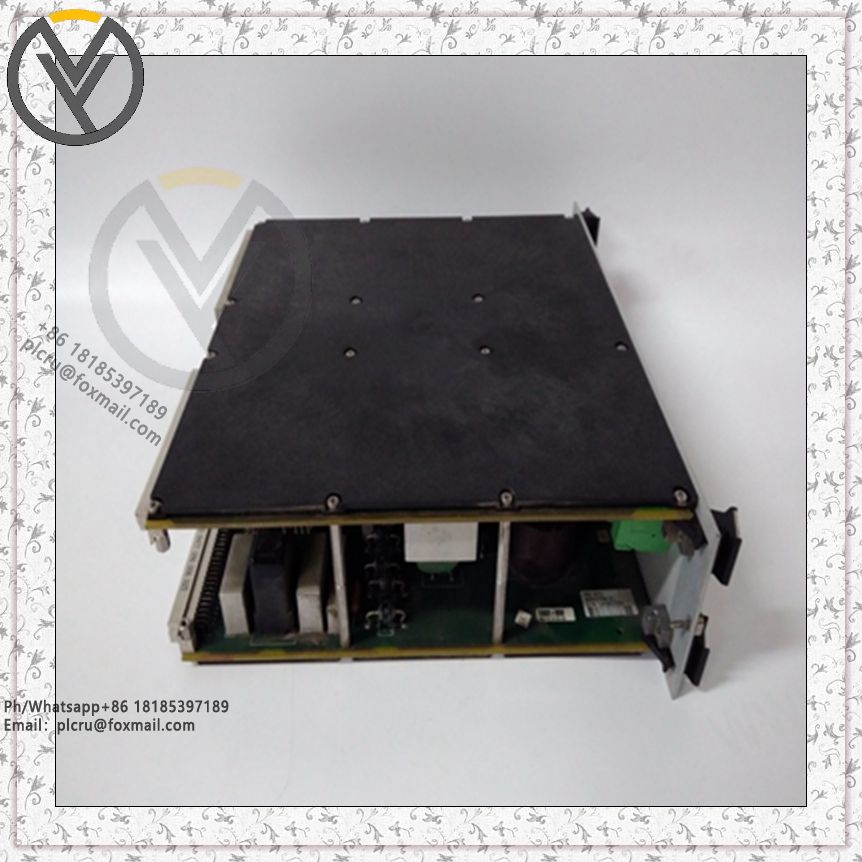

- Product Type: Actuator Control Module, which plays a bridging role between the controller and the actuator in the control system, responsible for accurately controlling the operation of the actuator.

- Input Signal: It can receive various control signals, such as 4 - 20mA analog current signals, 0 - 10V analog voltage signals, and digital signals conforming to specific communication protocols. This wide range of input signal compatibility allows it to be flexibly connected to different types of controllers.

- Output Signal: The output signal of the module is mainly used to drive the actuator, including voltage signals, current signals, and pulse - width - modulation (PWM) signals. The specific output signal type and range are determined according to the requirements of the actuator. For example, it may output a 0 - 24V DC voltage signal to control the speed of a DC motor - driven actuator, or output a PWM signal to control the opening degree of a servo - motor - driven valve.

- Communication Interface: It is usually equipped with communication interfaces such as RS - 485, CAN, and Ethernet. Through these interfaces, the module can exchange data with other devices in the control system, such as uploading the operating status information of the actuator to the upper - level controller and receiving control commands from the upper - level controller.

- Control Accuracy: It has high - precision control capabilities. For example, the control accuracy of the output signal can reach ±0.1% of the full scale, which can ensure the accurate operation of the actuator and meet the precise control requirements of the production process.

- High Reliability: The module adopts redundant design and fault - tolerant technology. For example, it is equipped with dual - redundant power supply modules to ensure normal operation in the event of a single power supply failure. In addition, it has strong anti - interference capabilities, which can effectively resist electromagnetic interference, voltage fluctuations, and other factors that may affect the accuracy of the control signal.

- Flexible Configuration: It has a programmable logic function, and users can configure and customize the control logic of the module according to specific application requirements through software programming. For example, users can set the start - up and shutdown sequence of the actuator, the speed - regulating mode, and the protection action mode.

- Comprehensive Monitoring and Diagnosis: The module is equipped with a built - in monitoring and diagnostic circuit, which can continuously monitor the operating status of the actuator and the module itself. It can detect faults such as over - current, over - voltage, and over - temperature in a timely manner and send out alarm signals. At the same time, it can also provide detailed fault information to help maintenance personnel quickly identify and troubleshoot problems.