Woodward |5466-425|High-Density Analog I/O Module

The Woodward 5466 - 425 High - Density Analog I/O Module is a high - performance control module designed for industrial applications. Here is a detailed introduction:

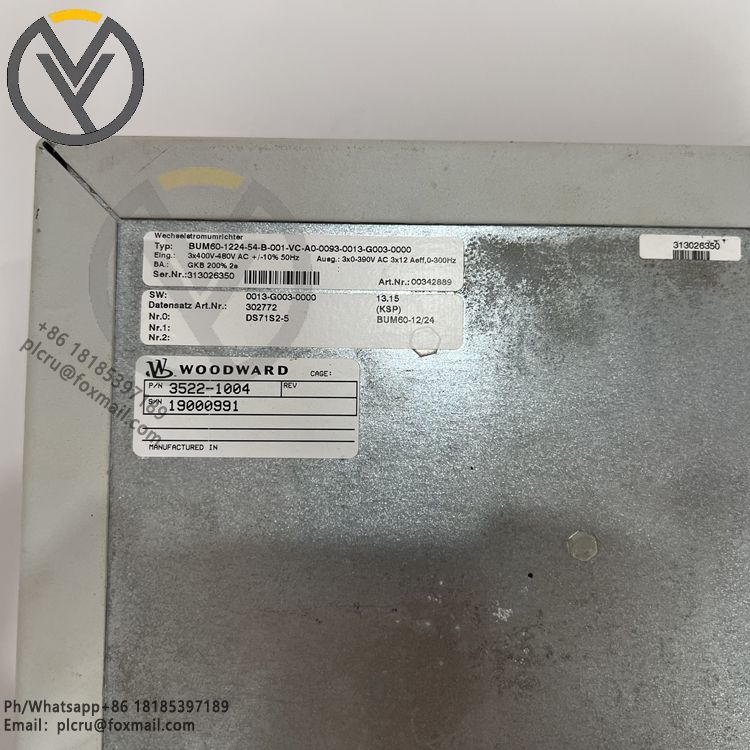

- Model Number: 5466 - 425

- Manufacturer: Woodward

- Product Type: High - Density Analog I/O Module

- Origin: USA

- Dimensions: 100mm × 50mm × 25mm

- Weight: 150g

- Certificates: CE, RoHS

- Input Voltage: 24V DC

- Output Voltage: 0 - 10V DC

- Operating Temperature: - 40℃ - 85℃

- Communication Protocol: Modbus

- High - Density Design: It has 24 analog input channels, which are divided into two banks. Data from channels 1 - 12 is collected 1.8 ms after the MFT tick, and data from channels 13 - 24 is collected 3.7 ms after the MFT tick. This design allows a large number of analog signals to be processed within a compact volume, optimizing space utilization.

- Signal Conditioning: The module can receive various analog signals such as voltage, current, temperature, and pressure. It provides reliable signal conditioning functions including amplification and filtering to optimize signal quality and integrity.

- Accurate Output: It is equipped with digital - to - analog converters (DACs) that generate precise analog signals, which can be used to control actuators, valves, motors, and other devices in industrial processes.

- Built - in Diagnostic Capabilities: It often includes built - in calibration and self - diagnostic features, which help maintain accurate and consistent measurements over time. Additionally, it offers protection mechanisms against overvoltage, overcurrent, and short circuits, safeguarding the module and the connected devices from potential damage.

- Easy Integration: The module can be seamlessly integrated with a variety of industrial control systems, such as programmable logic controllers (PLCs), distributed control systems (DCS), and supervisory control and data acquisition (SCADA) systems. It typically supports standard communication protocols, facilitating smooth integration with existing infrastructure and enabling efficient data exchange with other modules and devices.

- Industrial Automation: It can be used in industrial production lines to monitor and control process parameters such as temperature, pressure, and flow, so as to realize the automation and optimization of production processes.

- Power Generation and Energy: In power plants, wind farms, and other energy - related fields, it is used to monitor and control the operation of generators, turbines, boilers, and other equipment. It can collect real - time data of equipment parameters and send control commands to ensure the stable operation of the power generation system.

- Process Industry: In the chemical, petroleum, and other process industries, it is used to monitor and control the process parameters of the production process to ensure the stability and quality of the production process. For example, in a chemical reaction process, the module can monitor and control parameters such as temperature, pressure, and concentration in real - time to ensure the normal progress of the reaction.