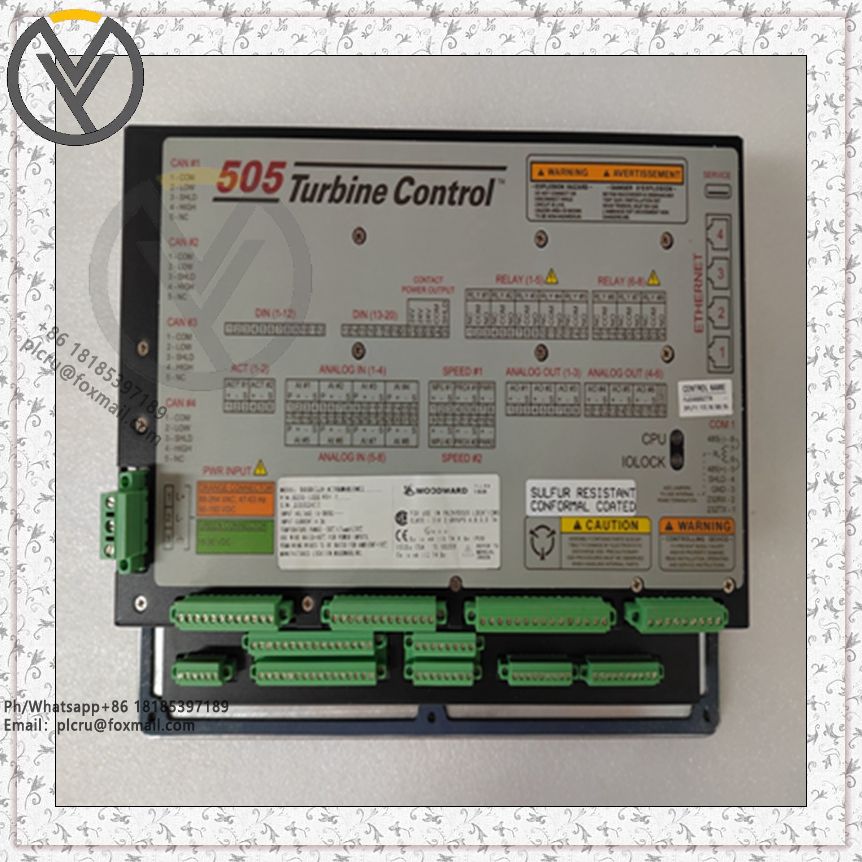

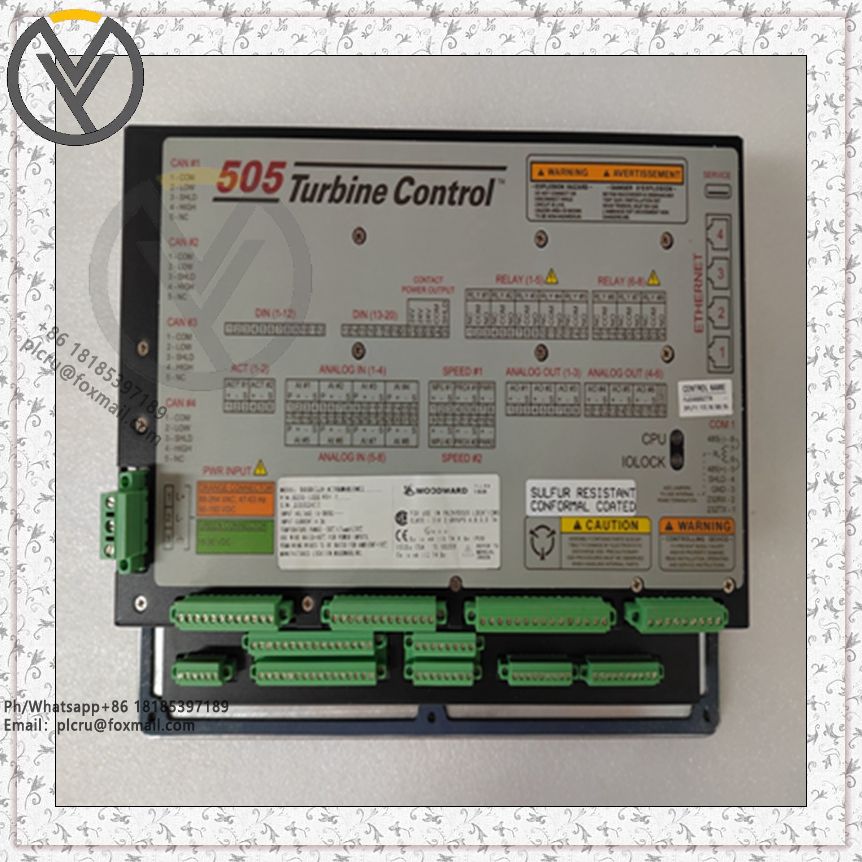

Woodward 5466-031 Network Controller Module

The Woodward 5466 - 031 Network Controller Module is a vital component in industrial control systems, mainly used for network communication and control in scenarios such as power generation and industrial automation. Here is an introduction:

- Network Communication: It has a built - in communication protocol stack that supports various industrial communication protocols, such as Modbus, Profibus, and Ethernet/IP. It can establish communication links with other devices in the industrial network, such as sensors, actuators, and programmable logic controllers (PLCs), to realize data exchange and control commands transmission.

- Data Processing and Control: After receiving data from the network, the module processes and analyzes it through an internal microprocessor. According to the pre - set control strategies and algorithms, it calculates the appropriate control output and sends control commands to the relevant devices to achieve the precise control of the industrial process. For example, in a power generation system, it can adjust the output power of the generator by controlling the excitation current and the opening degree of the turbine throttle based on the grid load demand.

- Power Generation Systems: In power plants, it is used to monitor and control the operation of generators, boilers, and turbines. It can collect real - time data of various parameters of the equipment, such as temperature, pressure, and rotational speed, and send control commands to adjust the operation status of the equipment to ensure the stable operation of the power generation system and the stability of the power grid connection. For example, when the grid frequency fluctuates, the network controller module can quickly adjust the speed of the generator to make the output frequency of the generator meet the grid requirements.

- Industrial Automation Production Lines: It is widely used in industrial automation production lines, such as those in the automotive, electronics, and food processing industries. It can connect various devices on the production line, such as conveyors, robots, and processing equipment, to form a network - based control system. It realizes the coordinated operation of the equipment through centralized monitoring and control, improves production efficiency and product quality, and reduces labor costs. For example, in an automotive assembly line, the network controller module can control the movement and operation of the robots to realize the precise assembly of automotive components.

- High - Speed Communication Capability: It supports high - speed communication protocols and has a fast data - processing ability, which can meet the requirements of real - time control in industrial applications. It can quickly transmit and receive data, reducing the communication delay and improving the response speed of the control system.

- Strong Compatibility and Expandability: It is compatible with a variety of industrial communication protocols and devices, which can be easily integrated into different industrial control systems. At the same time, it has good expandability, and can be expanded by adding modules or connecting other devices to meet the needs of system upgrades and expansions.

- High Reliability and Stability: It adopts industrial - grade components and a reliable design, which can operate stably in harsh industrial environments. It has functions such as anti - electromagnetic interference, anti - vibration, and anti - humidity, which can ensure the normal operation of the module in high - temperature, high - humidity, and strong - electromagnetic - interference environments.