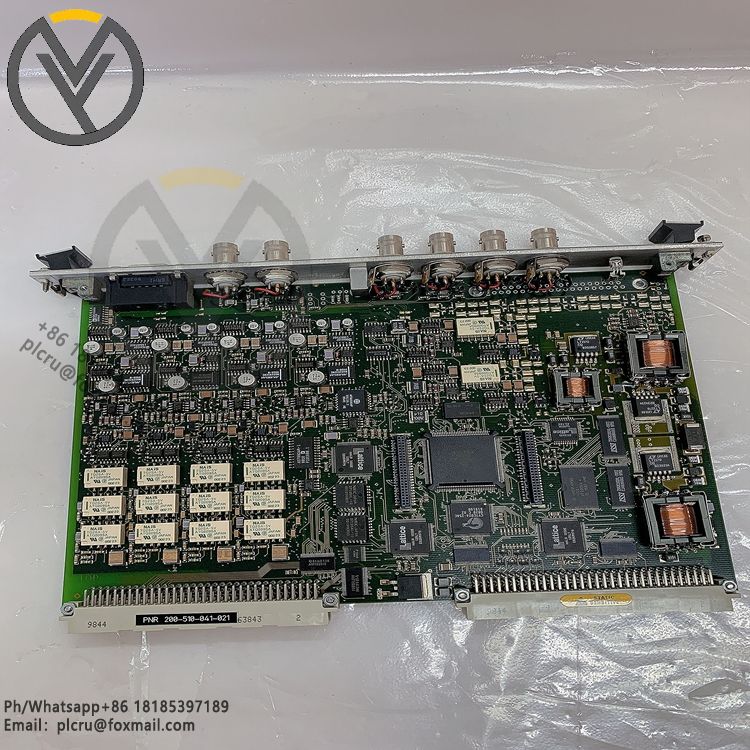

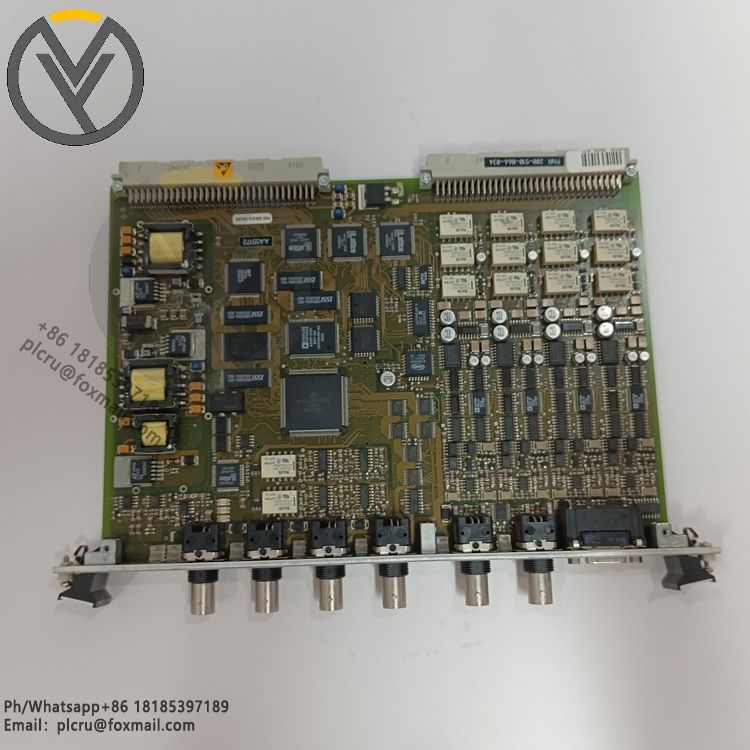

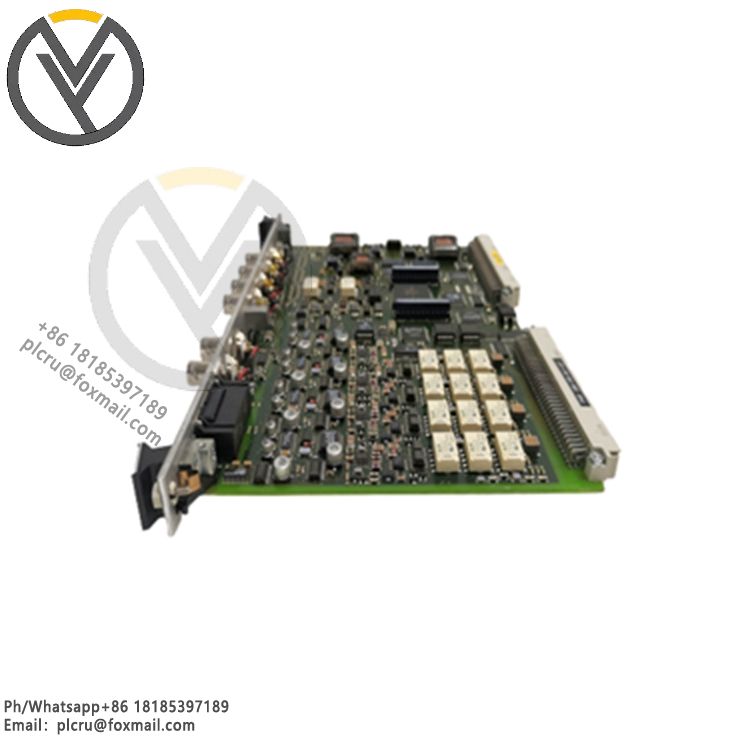

Vibro-meter MPC4 200-510-078-115 Machinery protection card

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

Vibro-meter MPC4 200-510-078-115 is a mechanical protection card for vibration m

Vibro-meter MPC4 200-510-078-115 is a mechanical protection card for vibration monitoring and protection of rotating machinery. It belongs to the Meggitt Vibro-Meter series and is widely used in the industrial field. The following is a detailed introduction:

Main features

High-precision monitoring: Suitable for real-time monitoring of shaft vibration, shaft displacement and housing vibration, it can provide accurate vibration amplitude and frequency information, which is helpful for early fault detection.

Multi-channel input: Usually supports 2~4 input channels, can monitor multiple vibration parameters at the same time, and is compatible with different types of vibration sensors such as eddy current probes, accelerometers, velocity sensors, etc.

Advanced signal processing: Adopts digital signal processing (DSP) technology to ensure high sensitivity and low noise measurement, and also has filtering and alarm logic functions, which can trigger alarms or shutdown signals under abnormal conditions.

Reliable protection function: Built-in threshold alarm, triggers alarms or shutdowns when vibration exceeds the safe range, and supports redundant configuration to enhance system reliability.

Industrial-grade design: Suitable for harsh industrial environments, high temperature resistance, anti-interference, and in line with international standards (such as API670). Standard 19-inch rack or modular installation is adopted, which is easy to integrate into the existing protection system.

Rich communication interface: Supports analog output (such as 4-20mA), relay output, Modbus and other industrial communication protocols, which is easy to integrate into DCS (distributed control system) or CMS (condition monitoring system).

Application areas

Steam turbines and gas turbines: can monitor shaft vibration and imbalance to ensure stable operation of equipment.

Generators and motors: protect equipment from mechanical damage by real-time monitoring of vibration.

Compressors: can detect bearing wear and abnormal vibration, detect potential failures in advance, and avoid equipment damage.

Pumps and fans: used for preventive maintenance, reduce unplanned downtime, and improve equipment availability and production efficiency.