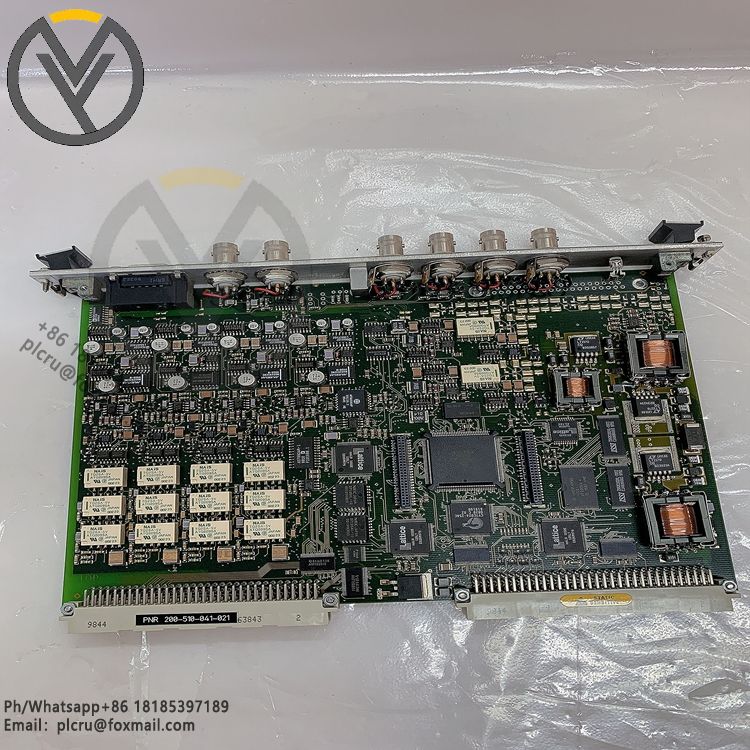

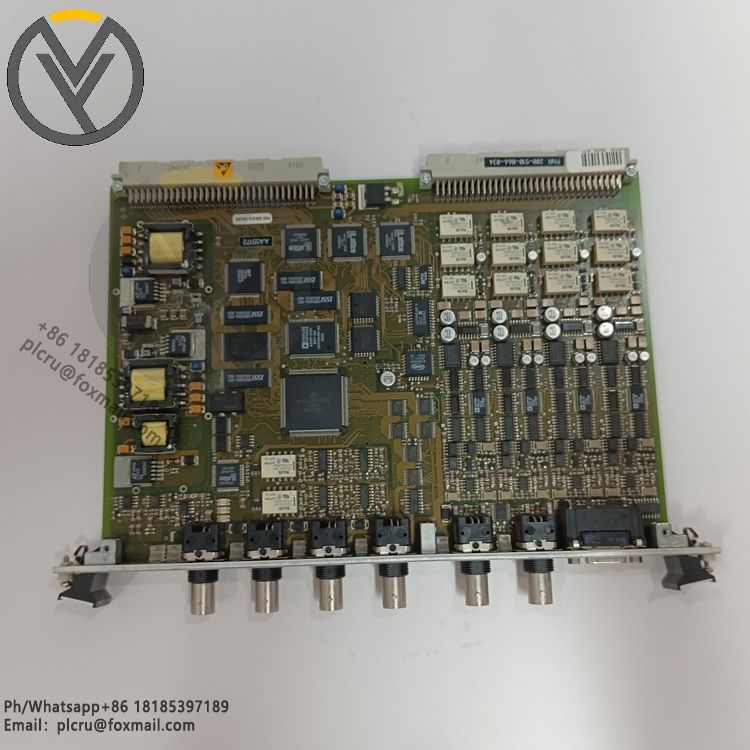

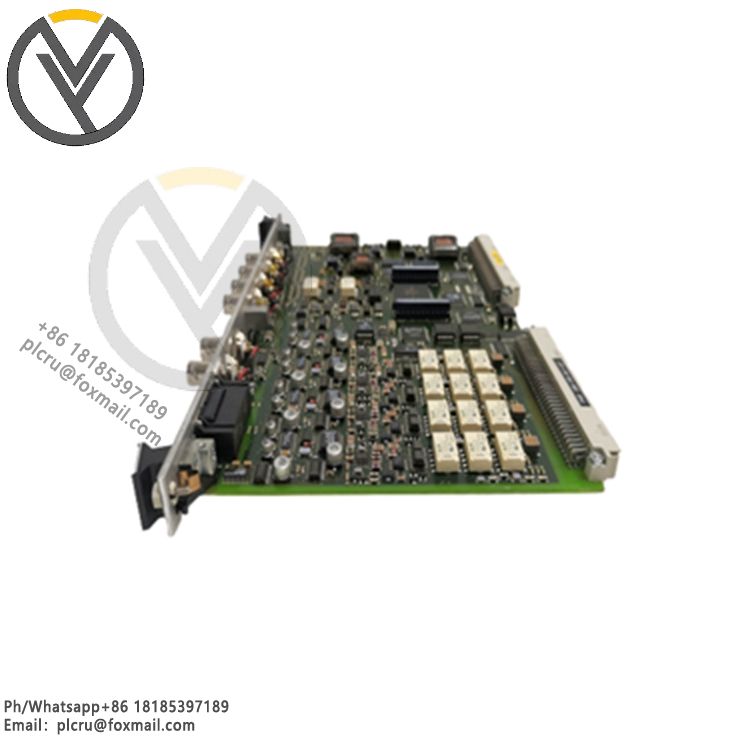

Vibro-Meter 200-510-077-313 Safety MPC4 Card

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

Vibro-Meter 200-510-077-313 Safety MPC4 Card is a safety card for mechanical pro

Vibro-Meter 200-510-077-313 Safety MPC4 Card is a safety card for mechanical protection produced by Vibro-Meter, belonging to the VM600 series. The following is its relevant introduction:

Features

Safety certification: Complies with IEC 61508 and ISO 13849 standards, and can be used in functional safety scenarios, such as SIL 1 in accordance with IEC 61508 and PL c in accordance with ISO 13849-1.

Multi-channel monitoring: Provides 4 dynamic channels and 2 tachometer (speed) channels, all channels can be configured independently, and can monitor multiple key parameters simultaneously.

Rich output options: Each dynamic channel has 2 processing outputs, each dual channel has 1 processing output, and each tachometer channel has 1 processing output, which can provide rich monitoring data for analysis and control.

Highly Configurable: Supports all measurements required for machinery protection applications, such as relative and/or absolute vibration, and can be flexibly configured according to different equipment and monitoring needs.

Highly Integrated: Forms a card pair with the IOC4T card, integrating sensor power supply, buffered output, DC output, relay and serial communication interface, etc., reducing the connection and complexity of external devices.

Front Panel Features: The front panel has a BNC connector for easy analysis of the buffered "raw" sensor signal, and there are LEDs to display status and alarms, which allows users to intuitively understand the operation of the equipment.

Application areas

Power plants: used for real-time vibration monitoring and fault warning of key equipment such as turbines and generators to ensure the stable operation of power generation equipment.

Oil and gas industry: suitable for the protection of drilling platforms, oil and gas extraction and processing equipment to ensure the stable operation of equipment in harsh environments and reduce production interruptions and safety accidents caused by equipment failures.

Manufacturing: can be applied to machine tools and production line equipment to avoid equipment failures caused by abnormal vibration through real-time monitoring, improve production efficiency and product quality.

Aerospace: used for the protection of important machinery such as aircraft engines to ensure the safe operation of key flight equipment, which is crucial to ensure aviation safety.

Mining and metallurgy: plays a role in mining equipment, smelting equipment and other fields, helping to reduce downtime and equipment damage, reduce maintenance costs, and improve production continuity.