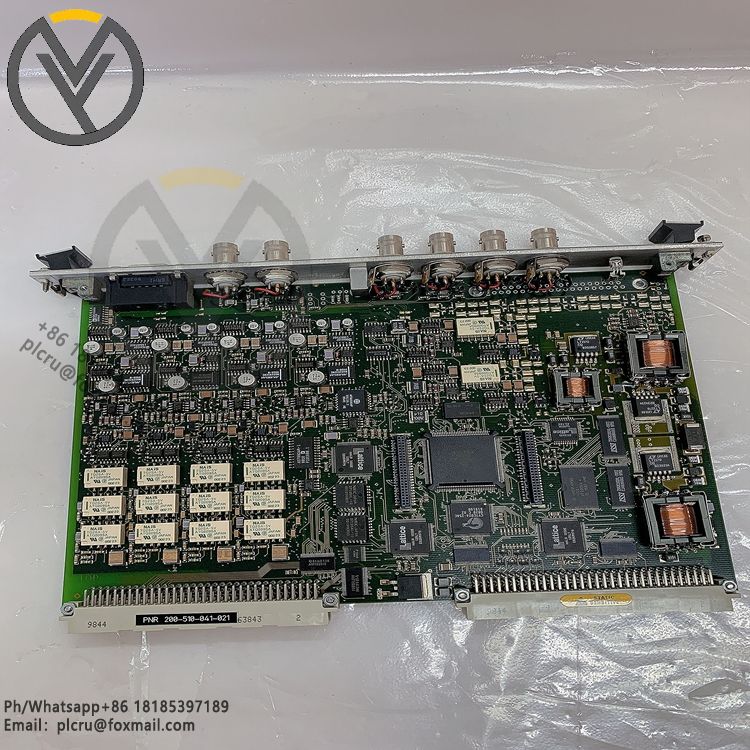

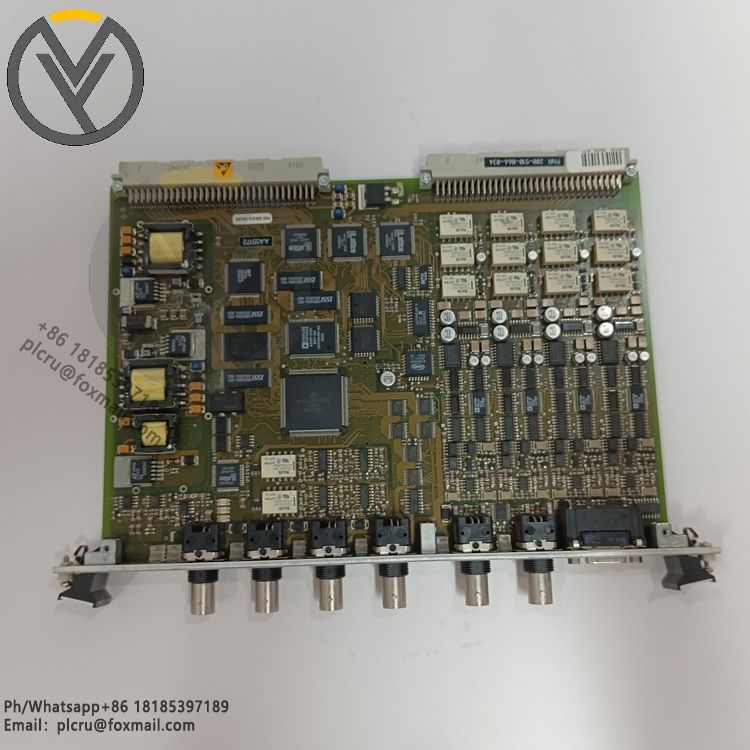

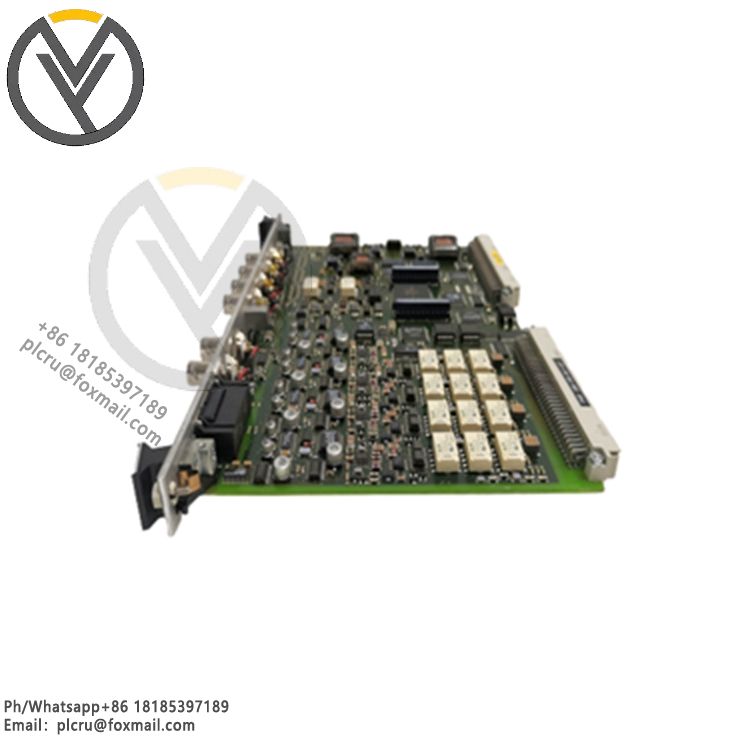

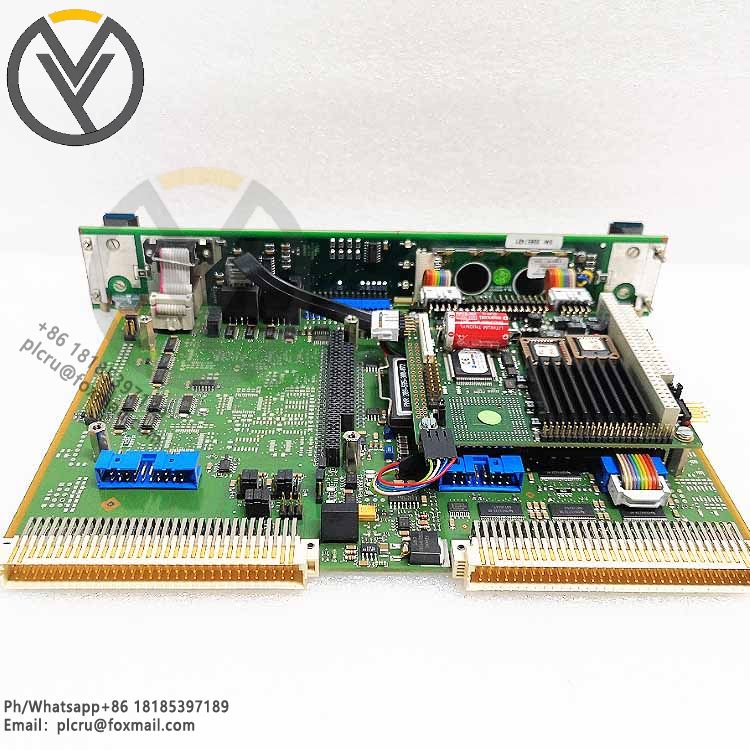

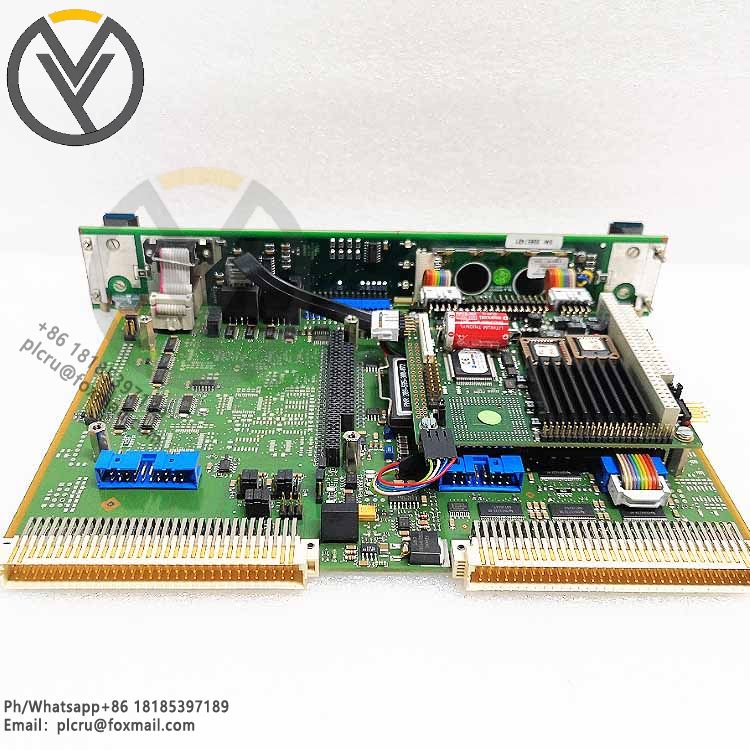

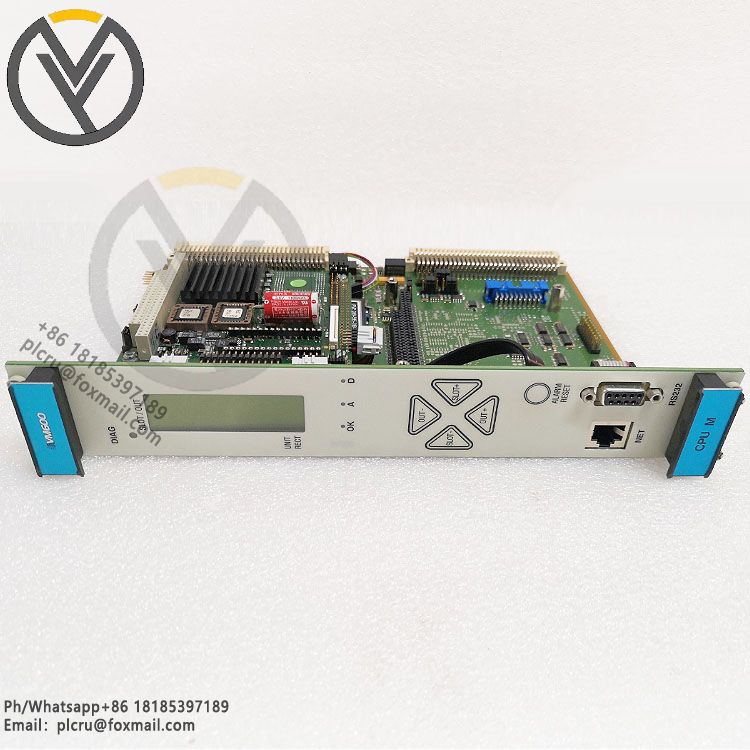

VIBRO Meter MPC4 200-510-076-114 Machinery protection card

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

The following is a detailed introduction to VIBRO Meter MPC4 200-510-076-114 Mac

The following is a detailed introduction to VIBRO Meter MPC4 200-510-076-114 Machinery protection card:

Overview

Brand and series: VIBRO Meter is a well-known manufacturer of vibration monitoring and analysis equipment. MPC4 200-510-076-114 belongs to its VM600 series of machinery protection cards.

Functional use: This machinery protection card is mainly used to monitor and protect industrial machinery, ensure the safe and reliable operation of key equipment, prevent equipment failure, reduce downtime and optimize maintenance activities.

Features

Multi-channel monitoring: Provides 4 dynamic channels and 2 tachometer (speed) channels, all channels can be configured independently, and can monitor multiple key parameters at the same time.

Rich output options: Each dynamic channel has 2 processing outputs, each dual channel has 1 processing output, and each tachometer channel also has 1 processing output, which can provide rich monitoring data for analysis and control.

Highly configurable: supports all measurements required for machinery protection applications, such as relative and/or absolute vibration, and can be flexibly configured according to different equipment and monitoring needs.

Highly integrated: forms a card pair with the IOC4T card, integrating sensor power supply, buffer output, DC output, relay and serial communication interface, etc., reducing the connection and complexity of external devices.

Software compatibility: designed for use with VM600 MPSX software, which can achieve powerful data analysis, fault diagnosis and alarm functions.

Application areas

Industrial machinery: suitable for monitoring various industrial machinery, including pumps, motors, compressors, turbines and generators, etc., which can monitor the operating status of these equipment in real time and detect potential faults in time.

Process industry: widely used in process industries such as oil and gas, power generation, chemical industry and manufacturing, it helps to ensure the continuity and stability of the production process and improve production efficiency.

Technical parameters

Input channel: with multiple input channels, various types of sensors can be connected, such as vibration sensors, temperature sensors, speed sensors, etc.

Interface type: using digital interface, it can be used for high-speed and accurate data transmission with other control systems or data acquisition equipment.

Measuring range: It can measure a wide range of parameters such as vibration, temperature, and speed, which can meet the monitoring needs of different industrial equipment.

Accuracy: It has high measurement accuracy and can accurately detect small changes in equipment operation, providing reliable data support for fault diagnosis.

Use and maintenance

Installation: It is usually installed on the front of the VM600 ABE04X rack and used in conjunction with the IOC4T card. The installation process must be carried out in accordance with the relevant installation guide to ensure that the installation is firm and the connection is correct.

Configuration: It is configured through the VM600 MPSX software or other dedicated configuration tools, and various parameters such as measurement range, alarm threshold, sampling frequency, etc. are set according to actual monitoring needs.

Maintenance: Regularly check the operating status of the card, clean the dust and dirt on the surface of the card, and ensure that the connection interface is not loose or corroded. At the same time, according to the operating conditions of the equipment and the manufacturer's recommendations, the card should be calibrated and performance tested regularly to ensure its measurement accuracy and reliability.

Technical Parameters

Input Channel: It has multiple input channels and can connect various types of sensors, such as vibration sensors, temperature sensors, speed sensors, etc.

Interface Type: It uses a digital interface, which can transmit data with other control systems or data acquisition equipment at high speed and accuracy.

Measurement Range: It can measure a wide range of parameters such as vibration, temperature, speed, etc., which can meet the monitoring needs of different industrial equipment.

Accuracy: It has high measurement accuracy and can accurately detect small changes in equipment operation, providing reliable data support for fault diagnosis.

Use and Maintenance

Installation: It is usually installed on the front of the VM600 ABE04X rack and used in conjunction with the IOC4T card. The installation process must be carried out in accordance with the relevant installation guide to ensure that the installation is firm and the connection is correct.

Configuration: It is configured through the VM600 MPSX software or other dedicated configuration tools, and various parameters such as measurement range, alarm threshold, sampling frequency, etc. are set according to actual monitoring needs.

Maintenance: Regularly check the operating status of the card, clean the dust and dirt on the surface of the card, and ensure that the connection interface is not loose or corroded. At the same time, according to the operation of the equipment and the manufacturer's recommendations, the card is calibrated and performance tested regularly to ensure its measurement accuracy and reliability.