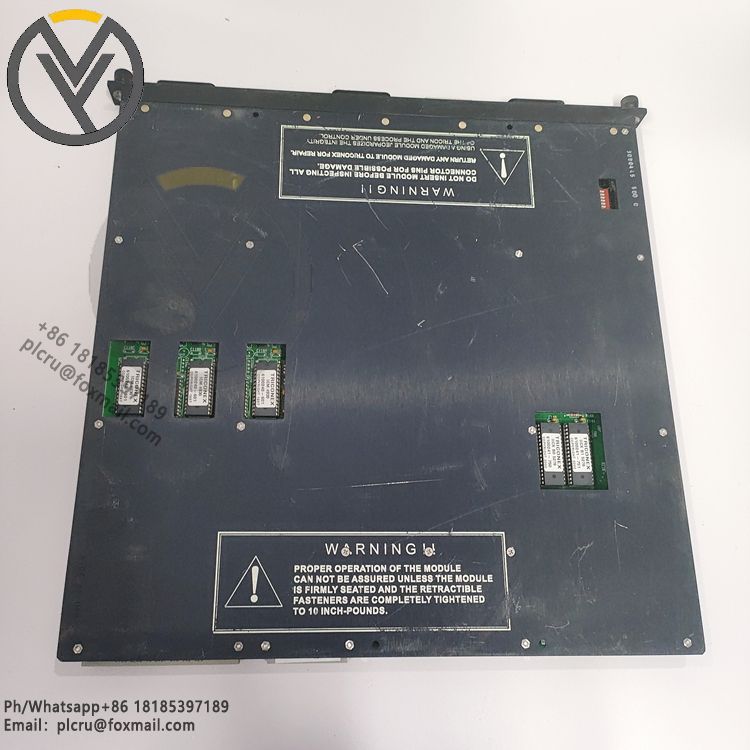

TRICONEX 9566-8XX Fault Tolerant Circuit Board

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

The TRICONEX 9566-8XX is the core fault-tolerant circuit board for the TRICONEX

The TRICONEX 9566-8XX is the core fault-tolerant circuit board for the TRICONEX safety control system, emphasizing high reliability and safety redundancy design. Typical sub-models include the 9566-810 and 9566-810F, adaptable to various industrial safety scenarios.

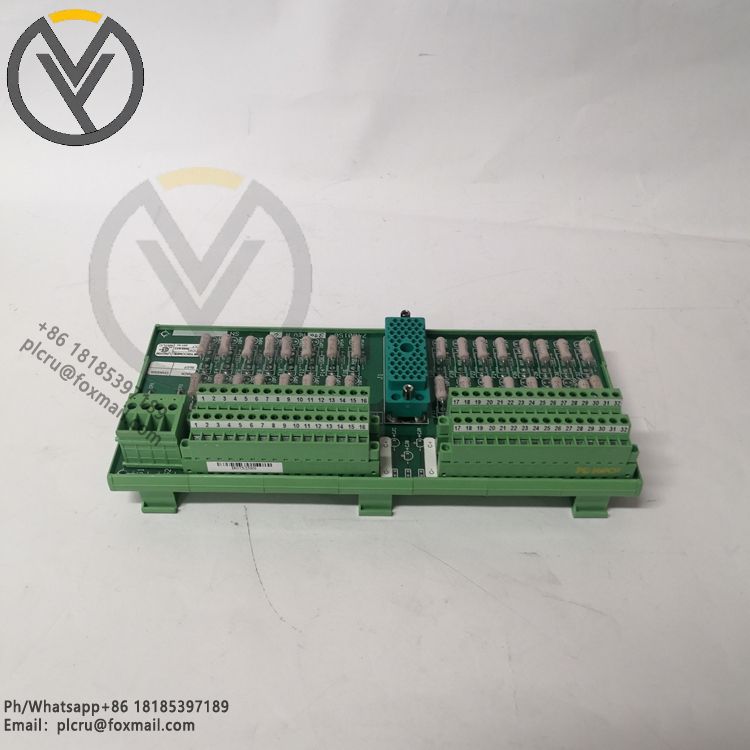

In terms of core configuration and performance, the 9566-810 is a 32-point redundant digital input module, while the 9566-810F is a high-end safety controller module equipped with a dual-core ARM Cortex-A9 processor. For power supply, the former uses a 24VDC operating voltage, while the latter supports dual modes of 120V AC input and 24V DC output. They exhibit outstanding environmental adaptability; the 9566-810 has an IP66 protection rating and an operating temperature range of -20°C to 60°C; the 9566-810F is upgraded to IP67, capable of withstanding harsh conditions such as high temperatures, dust, and chemical corrosion. Both models offer comprehensive communication capabilities, supporting Modbus and Ethernet protocols. The 9566-810F adds an additional HART communication port, adapting to a wider range of industrial bus requirements. In terms of safety certification, the 9566-810 complies with the IEC 61508 SIL 3 standard, while the 9566-810F achieves the higher SIL 4 safety level. Physically, the 9566-810 measures 300×150×75mm and weighs approximately 2kg; the 9566-810F features a dedicated terminal block panel for easy connection of power supplies, I/O devices, and communication cables, simplifying installation and wiring.

Functional advantages focus on a Triple Modular Redundancy (TMR) core architecture. Three independent system branches operate in parallel and execute control programs independently. In the event of a single point of failure, redundancy mechanisms provide immediate compensation, and online hot-swapping of faulty modules is supported without interrupting industrial production processes. The system automatically reconfigures to maintain stable operation in TMR mode. With robust fault handling capabilities and comprehensive real-time diagnostic functions, it can monitor the status of internal branches, circuits, and external connection components. When a fault occurs, it triggers an alarm via indicator lights and stores fault data in system variables, facilitating rapid problem localization. In terms of scalability, the entire series adopts a modular design, allowing for flexible combination with TRICONEX series power modules and communication modules. The 9566-810F terminal panel has reserved spare interfaces to meet future system expansion needs.

Application scenarios cover everything from general industrial applications to high-safety-level special fields: The 9566-810F is suitable for SIL 4 requirements scenarios such as nuclear power plant safety facility control and rail transit train control systems, preventing major safety accidents caused by signal or control failures. The 9566-810 is widely used for valve and pipeline monitoring in oil and gas fields and refineries, safety monitoring of chemical plant reactors and storage tanks, and safety control of power plant equipment to prevent large-scale power outages. The entire series can also be adapted to general industrial scenarios such as automated production lines, logistics equipment, and packaging machinery, enabling operational status monitoring and safety logic control of equipment such as robotic arms and transmission devices, reducing production interruptions caused by equipment failures.

Related products