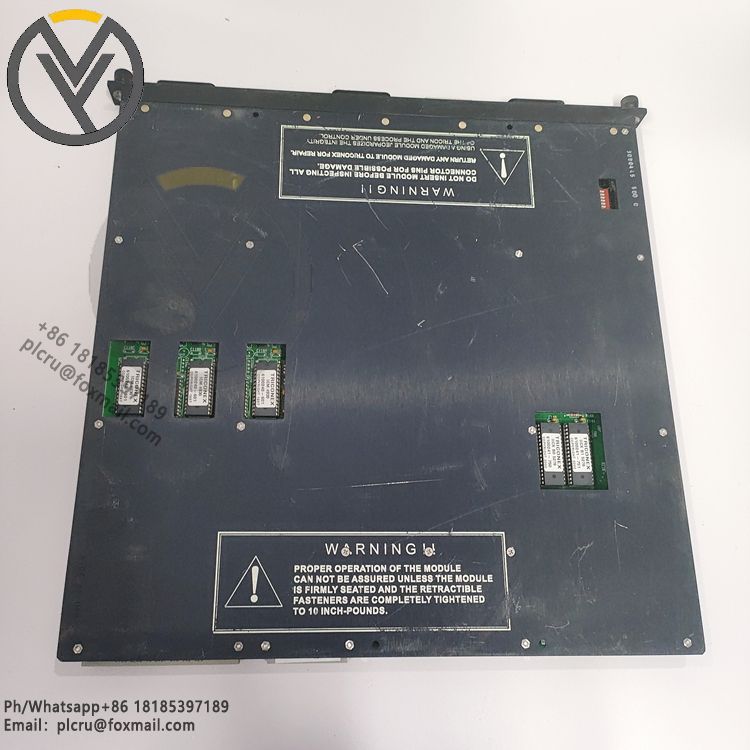

TRICONEX 5481-1S2 VDC Logic I/O Module

The TRICONEX 5481 - 1S2 VDC Logic I/O Module is a vital component in industrial automation and control systems, mainly used for processing and transmitting digital signals. Here is a detailed introduction:

- Model Number: 5481 - 1S2

- Manufacturer: TRICONEX, a company renowned for producing high - reliability industrial control products.

- Product Type: VDC Logic I/O Module, designed to handle logic - level input and output signals in a direct - current (DC) power supply environment.

- Input Voltage: Usually operates at a nominal DC voltage of 24V, with a tolerance range to accommodate some fluctuations in the power supply, ensuring stable operation within a certain voltage range.

- Output Voltage: Provides a stable DC output voltage that matches the input voltage level to drive external loads or supply power to other connected devices.

- Signal Type: Deals with digital logic signals, which can be either binary - coded signals representing on/off states or signals conforming to specific digital communication protocols.

- Communication Interface: It may support standard industrial communication protocols such as Profibus, Modbus, or Ethernet/IP, enabling seamless integration with other devices in the control system, facilitating data exchange and communication.

- High Reliability: Adopts advanced circuit design and high - quality components to ensure stable operation in harsh industrial environments, with strong anti - interference capabilities to resist electromagnetic interference, voltage fluctuations, and other factors that could affect signal integrity.

- Redundancy Design: In some critical applications, the module may support redundancy to improve system reliability and availability. This means that there are duplicate signal paths or backup modules to ensure continuous operation even in the event of a failure in one component.

- Programmable Logic Function: It has programmable logic capabilities, allowing users to configure and customize the logic functions according to specific application requirements through software programming, providing flexibility in different industrial control scenarios.

- Diagnostic and Alarm Functions: It is equipped with built - in diagnostic circuits and software, which can continuously monitor the operating status of the module. When a fault is detected, it can send out an alarm signal in a timely manner and provide relevant fault information to help maintenance personnel quickly identify and troubleshoot problems, reducing system downtime.

- Petrochemical Industry: It is used in the control systems of oil refineries, chemical plants, and gas processing facilities to monitor and control the opening and closing of valves, the operation of pumps, and the status of various process switches, ensuring the safe and stable operation of the production process.

- Power Generation Industry: In power plants, including thermal power, hydropower, and nuclear power plants, it is used to control the start - up and shutdown of generators, the switching of circuit breakers, and the monitoring of various protection signals, playing a crucial role in ensuring the normal operation of the power grid and the safety of equipment.

- Metallurgical Industry: In steel mills and other metallurgical enterprises, it is applied to the control of the casting process, the adjustment of rolling mill equipment, and the monitoring of the working status of furnaces. By accurately controlling the on - off of various actuators and the transmission of signals, the production efficiency and product quality are improved.

- Industrial Automation Production Lines: It is widely used in automotive manufacturing, electronics manufacturing, and other production lines to control the operation of robots, conveyors, and various automated equipment, realizing the automation and intelligentization of the production process and improving production efficiency and product quality.