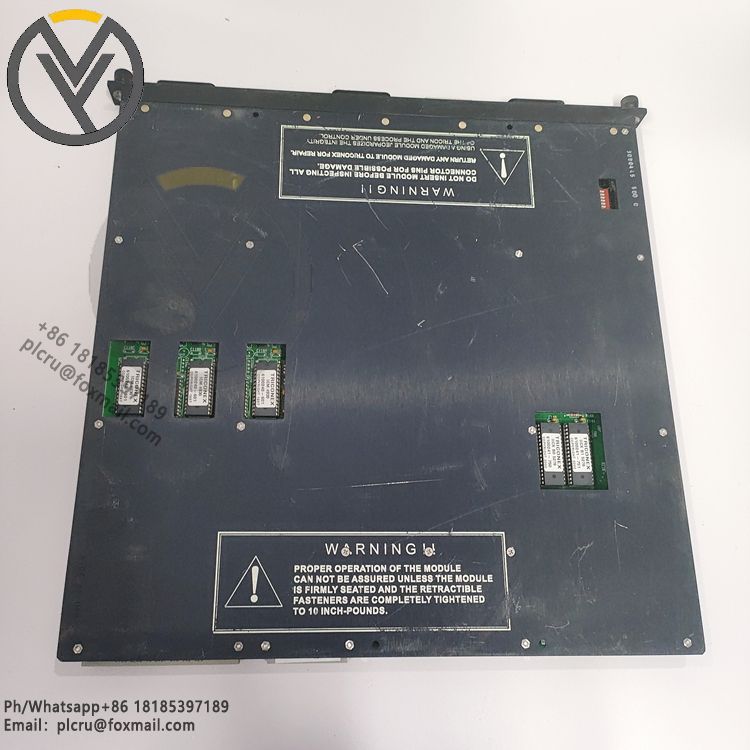

TRICONEX CIM 3211S2 Tricon Communication Model

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

TRICONEX CIM 3211S2 is a Tricon communication module launched by TRICONEX, which

TRICONEX CIM 3211S2 is a Tricon communication module launched by TRICONEX, which is mainly used for communication tasks in industrial automation control systems. The following is a related introduction:

Functional features

High reliability: It adopts redundant design and fault-tolerant mechanism, which can operate stably in harsh industrial environments and ensure the reliability and stability of communication.

Multiple communication protocol support: It supports multiple industrial communication protocols, such as HART, Profibus, Modbus, etc., and can communicate and integrate with equipment from different manufacturers.

Real-time communication capability: It can realize real-time data transmission and meet the real-time requirements of industrial automation control systems.

Diagnosis and maintenance functions: It has powerful diagnostic functions, which can monitor the communication status and equipment operation status in real time, facilitate quick positioning and troubleshooting, and reduce maintenance costs.

Technical parameters

Power supply voltage: Usually 24V DC.

Communication interface: It has multiple communication interfaces, such as RS-232, RS-485, Ethernet, etc., which can be selected according to actual needs.

Communication rate: It supports multiple communication rates and can be configured according to specific application scenarios.

Working temperature range: generally - 40℃ to + 85℃, adapting to different industrial environment temperatures.

Application scenarios

Petrochemical industry: In the petrochemical production process, it is used to connect various automation equipment, such as sensors, actuators, controllers, etc., to realize the monitoring and control of the production process.

Power industry: In the power system, it can be used to connect substation automation equipment, generator set control systems, etc., to realize the automatic operation and management of the power system.

Metallurgical industry: In metallurgical production, it is used to connect blast furnace automation systems, continuous casting and rolling control systems, etc., to improve production efficiency and product quality.

Other industrial fields: It is also widely used in automation control systems in industrial fields such as pharmaceuticals, food and beverages, and water treatment.