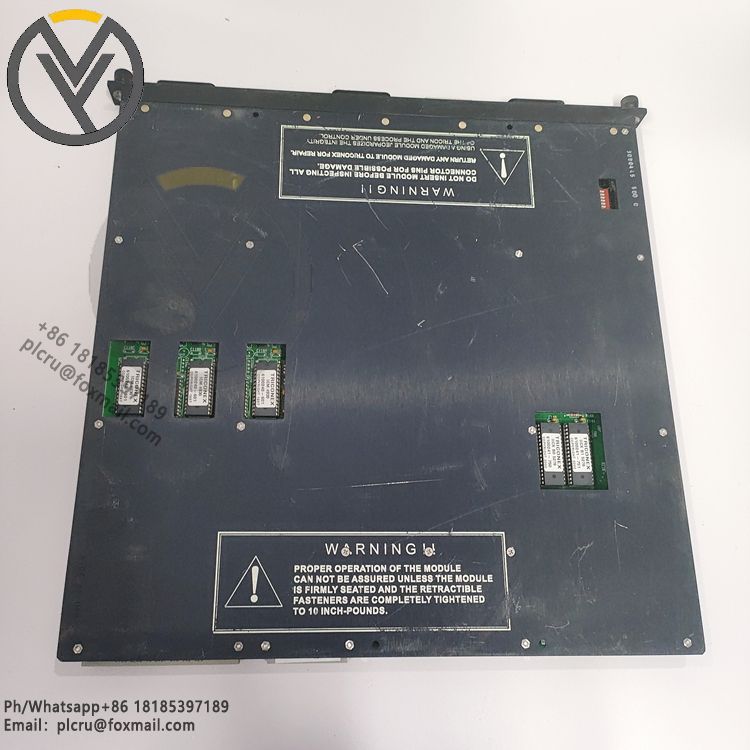

Triconex MP3008 Main Processor Module

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

The Triconex MP3008 main processor module is a key device used in the field of i

The Triconex MP3008 main processor module is a key device used in the field of industrial automation control. The following is a detailed introduction about it:

Features

High reliability: It adopts a triple-module redundant (TMR) architecture, integrates three independent processor cores, processes input signals in parallel, and uses a voting mechanism to ensure the accuracy and reliability of the output results. Even if one of the processor cores fails, the other two normal cores can still ensure that the system continues to operate stably, greatly reducing the risk of system downtime or errors caused by single-point failures.

Powerful processing capabilities: It has high-speed computing speed and efficient instruction execution capabilities, and can quickly process large amounts of real-time data and complex control logic. It can process multiple input and output signals at the same time to achieve accurate monitoring and control of various parameters in the industrial process, and meet the complex control requirements in different industrial scenarios.

Rich communication interfaces: It supports a variety of industrial communication protocols, such as HART, Profibus, Modbus, FF, etc., and can easily interact and integrate data with other devices and systems. It can be seamlessly connected with the host computer monitoring system, other controllers, intelligent instruments, etc., to achieve networking and intelligent management of industrial automation systems.

Flexible configuration mode: It provides intuitive and convenient configuration software, and users can easily configure, program and debug the system according to actual needs. Various control parameters, logical relationships and alarm conditions can be flexibly set to meet the control requirements of different industrial processes, shortening the project development cycle and debugging time.

Wide working environment adaptability: It has good anti-interference ability and wide temperature working range, and can work stably in harsh industrial environments. It can adapt to various harsh conditions such as high temperature, low temperature, humidity, dust, electromagnetic interference, etc., to ensure reliable operation in different industrial field environments.

Function

Data processing and calculation: Collect, filter, amplify, convert and other pre-processing of analog and digital signals from field equipment (such as sensors, transmitters, etc.), and perform complex calculations and processing according to preset control algorithms and logic to generate corresponding control instructions.

Logic control: Realize various logic operations and control functions, such as AND, OR, NOT, timer, counter, etc., and perform flexible logic programming according to the requirements of industrial processes to realize the start and stop, sequence control, interlocking protection and other functions of the equipment to ensure the safety and stability of the industrial production process.

Real-time monitoring and alarm: Real-time monitoring of various parameters and equipment status in the industrial process. When it is detected that the parameters exceed the set threshold or the equipment is abnormal, it can issue an alarm signal in time and take corresponding measures to deal with it, such as automatic shutdown, switching to standby equipment, etc., to avoid the occurrence and expansion of accidents.

System management and maintenance: With system management and maintenance functions, it can monitor and diagnose its own operating status, provide fault alarm and diagnostic information, and facilitate maintenance personnel to find and troubleshoot faults in time. At the same time, it also supports remote monitoring and maintenance functions, and can remotely configure, program and debug the module through the network, which improves the maintenance efficiency and convenience of the system.

Application field

Petrochemical industry: used for the control and protection of key equipment in the process of petroleum refining and chemical production, such as reactors, distillation towers, compressors, pumps, etc. It can ensure the safe and stable operation of the production process, prevent safety accidents and production losses caused by equipment failure or operational errors, and improve production efficiency and product quality.

Power industry: In power facilities such as power plants and substations, it is used for the control of generator sets, the dispatching and protection of power grids, and the automation control of power systems. It can ensure the reliable power supply and stable operation of the power system, and plays a vital role in the safe and stable operation of the power system.

Metallurgical industry: Applied to the automation control of steel production, non-ferrous metal smelting and other processes, such as blast furnace ironmaking, converter steelmaking, continuous casting and rolling, electrolytic aluminum and other links. It can improve production efficiency, reduce energy consumption, improve product quality, and realize the automation and intelligence of the metallurgical production process.

Transportation industry: In the fields of rail transportation, airports, ports, etc., it is used for traffic signal control, train operation control, airport runway lighting control, port loading and unloading equipment control, etc. It can ensure the safe and efficient operation of transportation, and improve the automation level and service quality of transportation.