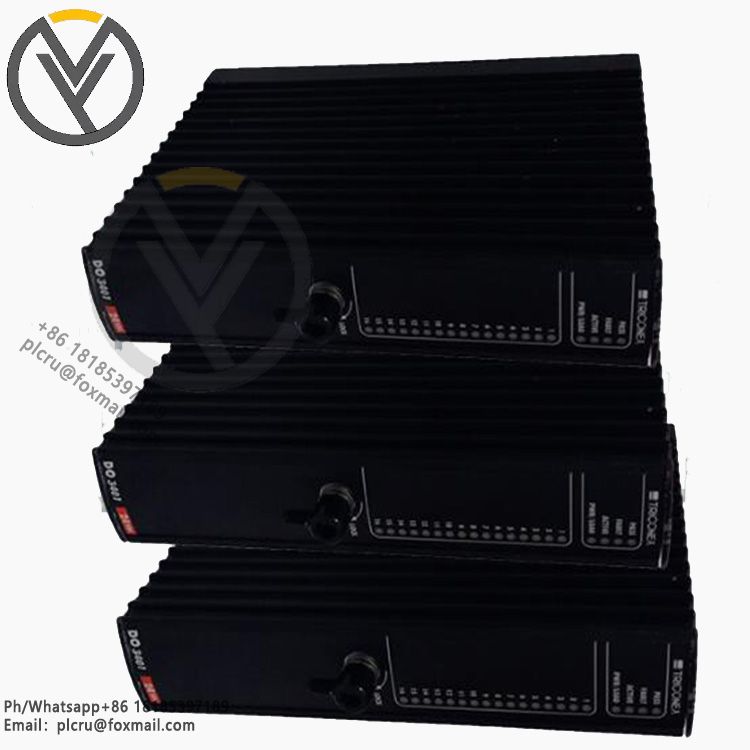

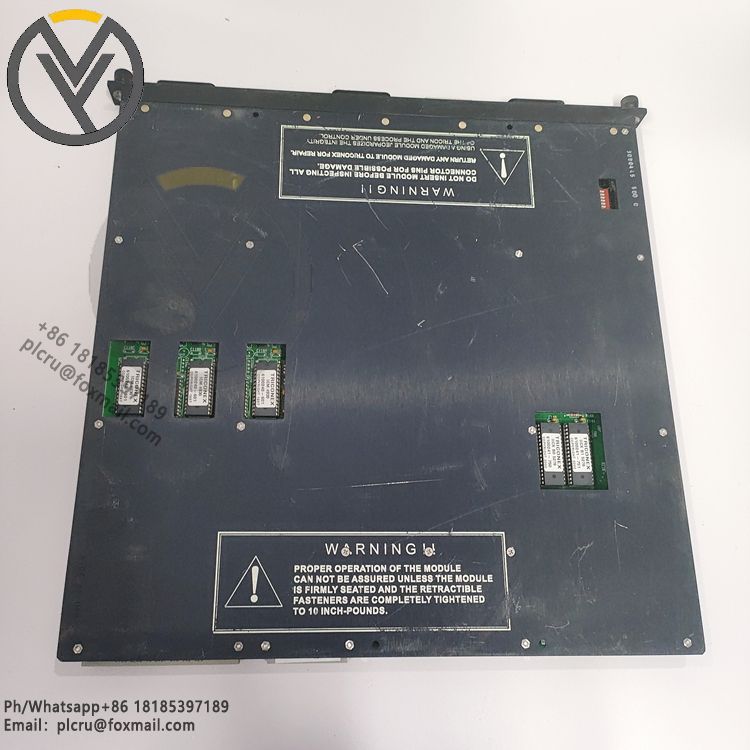

3004 | Triconex MAIN PROCESSOR MODULE

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

FeaturesHigh reliability: Adopting triple-mode redundant (TMR) architecture, the

Features

High reliability: Adopting triple-mode redundant (TMR) architecture, the input signal is processed through three independent processor cores, and the results are compared and voted. If one of the processor cores fails, the other two normal cores can continue to work, ensuring the continuity and stability of the system, effectively reducing the probability of system failure, and improving overall reliability.

Powerful processing capability: It can quickly process a large amount of real-time data and complex control logic, and can process multiple input and output signals at the same time to achieve precise control and monitoring of industrial processes, meeting the needs of various industrial automation scenarios.

Strong real-time performance: With high-speed computing speed and precise timing function, it can respond to input signals in a very short time, ensure the real-time control performance of the system, and can handle various emergencies and emergencies in time to ensure the safety and stability of industrial production.

Rich communication interfaces: Support multiple communication protocols, such as HART, Profibus, Modbus, etc., which can easily interact and integrate with other devices and systems, realize the networking and intelligence of industrial automation systems, and facilitate connection with host computer monitoring systems, other controllers or smart instruments, etc.

Application areas

Petrochemical industry: used for the control and protection of key equipment in the process of oil refining and chemical production, such as reactors, distillation towers, compressors, etc., to ensure the safe and stable operation of the production process and prevent safety accidents and production losses caused by equipment failure or operational errors.

Power industry: in power plants, substations and other power facilities, used for the control of generator sets, the dispatching and protection of power grids, etc., to ensure the reliable power supply and stable operation of the power system, which plays a vital role in the safe and stable operation of the power system.

Metallurgical industry: used for automated control in the processes of steel production and non-ferrous metal smelting, such as blast furnace ironmaking, converter steelmaking, continuous casting and rolling, etc., to improve production efficiency and product quality, and reduce energy consumption and production costs.

Transportation industry: in rail transportation, airports and other fields, used for traffic signal control, train operation control, airport runway lighting control, etc., to ensure the safety and efficient operation of transportation and provide safety protection for people's travel.

Working principle

Signal input: Receive analog or digital signals from field equipment (such as sensors, transmitters, etc.), which represent various parameters in the industrial process, such as temperature, pressure, flow, liquid level, etc.

Data processing: Pre-process the input signal by filtering, amplifying, converting, etc., and then the three processor cores respectively calculate and process the pre-processed data, and generate corresponding control instructions according to the preset control algorithm and logic.

Voting and output: Compare and vote on the processing results of the three processor cores, and adopt the majority voting principle, that is, if the results of two or three processor cores are consistent, the result is considered to be correct, and it is output as the final control instruction to the field execution equipment (such as control valves, motors, etc.) to achieve control of the industrial process.

Maintenance and maintenance

Regular inspection: Regularly inspect the appearance of the module to check whether there is dust, oil, corrosion, etc., check the status of the module indicator light, determine whether the module is working normally, and check whether the module connection cable is loose or damaged.

Cleaning and maintenance: Clean the module regularly with a clean soft cloth or compressed air to remove dust and debris on the surface of the module to prevent dust accumulation from affecting the heat dissipation and performance of the module, and ensure that the module is well ventilated.

Software update: Update the module's operating system and application in a timely manner to fix software vulnerabilities, improve performance, and add new features. Before updating the software, you need to back up important data and configuration information to prevent data loss.