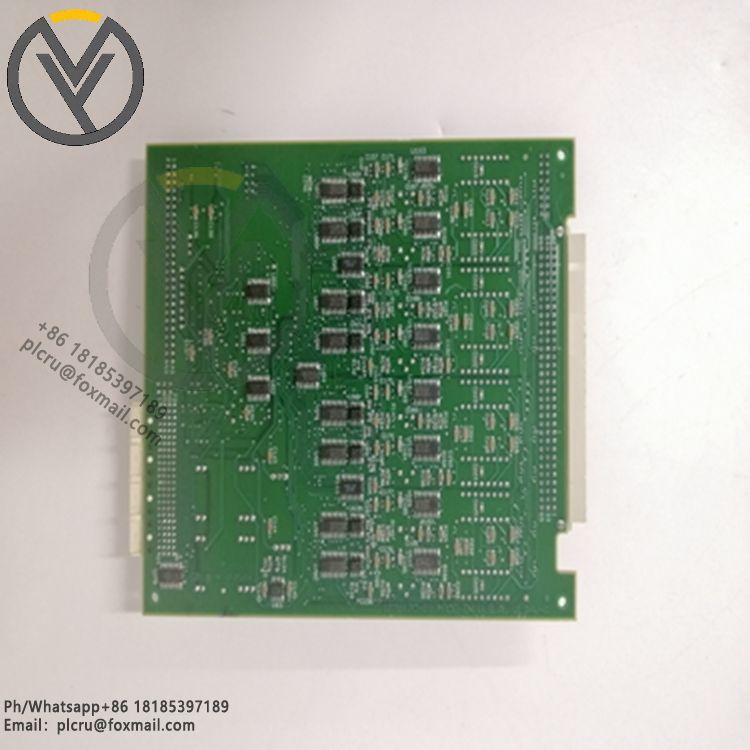

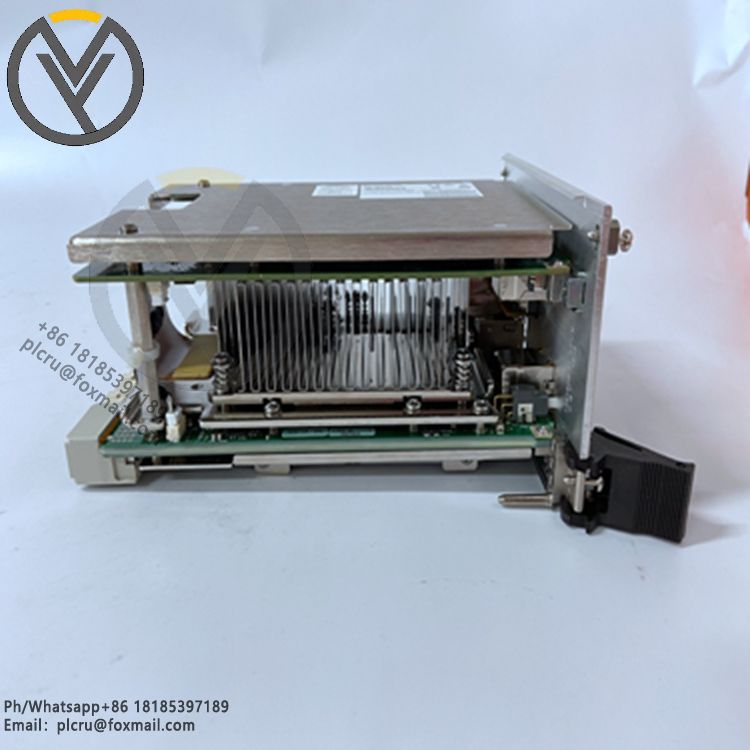

NI 782878-01 PXIe-4322 Isolated Analog Output Module

The NI 782878 - 01 PXIe - 4322 Isolated Analog Output Module is a high - performance module designed for applications requiring isolated analog output in PXI - based systems. Here is a detailed introduction:

Features

- Isolated Channels: It has 8 isolated analog output channels, which can effectively prevent crosstalk and interference between channels, ensuring the accuracy and stability of each channel's output signal. This is particularly important in applications where multiple analog signals need to be output simultaneously and the isolation of each channel is required, such as in some high - precision measurement and control systems.

- High Resolution: With a 16 - bit resolution, it can provide a high - precision analog output signal. This allows for fine - grained control of the output voltage or current, enabling accurate adjustment of the controlled device or process. It can meet the requirements of applications that demand high - precision analog control, such as in scientific research experiments and high - end industrial automation.

- Programmable Output Range: The output range of the module is programmable. It can output currents in the range of 0 - 20 mA as set by software. This wide output range can meet the needs of different types of load devices, and the software - programmable feature provides users with the flexibility to configure the output range according to specific application requirements.

- High Output Drive Capability: It has a certain output drive capability. For the 0 - 20 mA output range, it can drive a load resistance of up to 450 Ω. This ensures that the module can provide sufficient driving force to drive various load devices, such as solenoid valves, actuators, and some sensors that require a certain driving current.

- Low Error1: The module has a low - error characteristic, with a full - scale range error of 0.1%. This high accuracy ensures that the output analog signal is close to the ideal value, reducing measurement and control errors and improving the overall performance of the system.

Technical Specifications

- Channel Quantity: 8 isolated analog output channels.

- Resolution: 16 bits.

- Output Current Range: 0 - 20 mA (software - programmable).

- Output Load Resistance: Up to 450 Ω for 0 - 20 mA output.

- Full - Scale Range Error: 0.1%.

- Power Consumption1: For PXIe bus, the maximum power consumption is + 12 V @ 800 mA.

- Working Temperature1: 0 °C - 50 °C.

- Storage Temperature1: - 20 °C - 80 °C.

- Relative Humidity1: 5% - 85% RH (working, non - condensing); 5% - 95% RH (storage, non - condensing).

Application Scenarios

- Industrial Automation Control: In industrial automation production lines, it can be used to control the speed of motors, the opening degree of valves, and the position of actuators. By outputting analog signals, it accurately controls the operation of these devices, realizing the automation and precise control of industrial production processes. For example, in the chemical industry, it is used to control the flow rate of chemical raw materials by adjusting the opening degree of control valves; in the textile industry, it controls the speed of motors to achieve precise control of the running speed of textile machinery.

- Laboratory Testing and Research: In scientific research laboratories, it is often used to provide analog excitation signals for various experimental equipment. Such as in electronic circuit experiments, it provides a precise voltage or current signal to test the performance and characteristics of circuits; in physical experiments, it is used to control the strength of magnetic fields, the temperature of heating equipment, and other parameters to meet the specific requirements of experimental conditions.

- Process Monitoring and Control: In the process of industrial production, it is used for process monitoring and control. By outputting analog signals to control the operation of sensors and data acquisition equipment, it realizes real - time monitoring of process parameters such as temperature, pressure, and flow. At the same time, according to the monitoring results, it can adjust the relevant control parameters through the analog output module to ensure the stability and quality of the production process. For example, in the food processing industry, it monitors and controls the temperature and humidity of the production environment to ensure the quality and safety of food products.