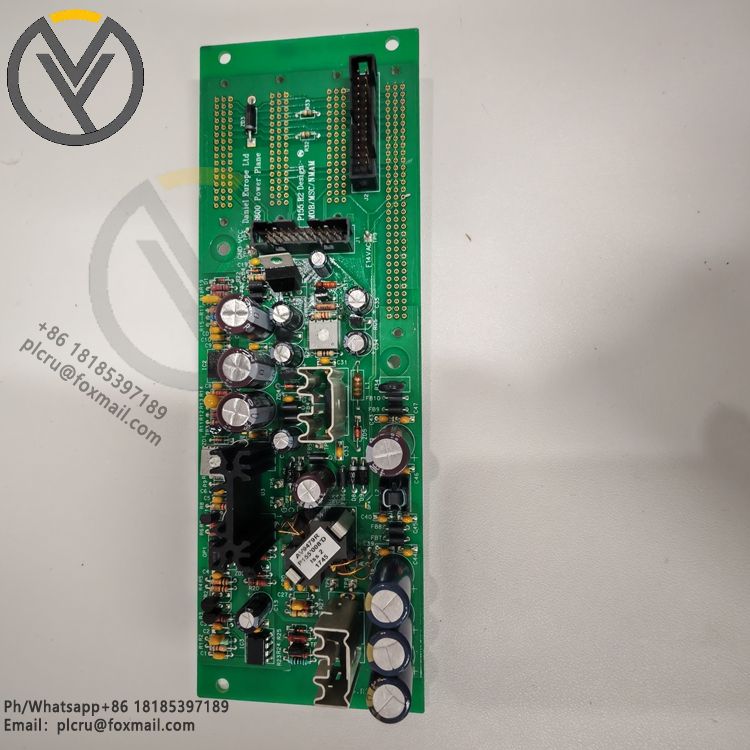

Emerson 5X00481G04 Ovation Controller CPU Card

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

Emerson 5X00481G04 Ovation Controller CPU Card is the core processing unit in Em

Emerson 5X00481G04 Ovation Controller CPU Card is the core processing unit in Emerson Ovation control system. Here are some introductions about it:

Functional features

High-performance processing capability: It adopts advanced microprocessor technology, has powerful computing power and data processing speed, can quickly execute complex control algorithms and logical operations, and process a large amount of process data and control instructions in real time to ensure the efficient operation of the control system. For example, in large-scale industrial automation projects, it can handle control tasks of multiple loops at the same time to achieve precise control of the production process.

Rich interface types: Equipped with a variety of communication interfaces, such as Ethernet interface, serial port, etc., it is convenient to communicate and exchange data with other devices. The Ethernet interface can be used to connect to the host computer, engineer station, operator station, etc. to realize centralized monitoring and management of the system; the serial port can communicate with some specific field equipment or intelligent instruments to expand the functions of the system.

Reliable system architecture: It has a redundant design and usually adopts a dual CPU or multi-CPU architecture. When one CPU fails, the other CPU can automatically take over the work to ensure the continuity and reliability of the system. At the same time, it has a complete error detection and correction mechanism, which can timely detect and handle data transmission errors, hardware failures and other problems, and improve the stability of the system.

Flexible programming and configuration: Supports multiple programming languages and programming tools, such as ladder diagrams, function block diagrams, structured text, etc., which is convenient for engineers to program and configure according to specific control requirements. In addition, it also provides a rich software library and function modules, which can greatly shorten the project development cycle and improve programming efficiency.

Technical specifications

Processor type: Usually a dedicated industrial-grade microprocessor is used, which has the characteristics of low power consumption and high reliability, and can work stably in harsh industrial environments. For example, processors from the PowerPC, ARM and other series may be used, with a main frequency of hundreds of MHz or even higher.

Memory capacity: Equipped with large-capacity memory, including random access memory (RAM) and read-only memory (ROM). RAM is used to temporarily store running programs and data, and the general capacity is between a few MB and tens of MB; ROM is used to store system programs and solidified configuration information, and the capacity is usually around a few MB.

Communication interface specifications: Ethernet interfaces generally support 10/100Mbps adaptive rate, comply with IEEE 802.3 standards, and can be connected to the network through RJ-45 interfaces; serial ports may include RS-232, RS-485 and other types, supporting different baud rates, such as 9600bps, 19200bps, etc., to meet the communication needs of different devices.

Operating temperature range: Adapt to a wider operating temperature range, generally - 40℃ to 70℃, and can operate normally in harsh industrial field environments such as high and low temperatures. At the same time, it has good resistance to humidity, vibration and electromagnetic interference to ensure stable operation in complex industrial environments.

Application scenarios

Industrial automation control: widely used in petrochemical, electric power, metallurgy, papermaking, pharmaceutical and other industrial fields, used to realize automatic control of production processes, such as precise control of process parameters such as temperature, pressure, flow, liquid level, and control of the start and stop and operating status of equipment such as motors, valves, pumps, etc.

Process control system: In large process control systems, as the core controller, it is responsible for coordinating and managing the communication and data interaction between various subsystems to achieve the optimization and coordinated operation of the entire production process. For example, in a chemical production device, the control of various reactors, distillation towers, pipelines and other equipment can be integrated into one system, and unified control and management are performed through the Ovation Controller CPU Card.

Energy management system: In energy fields such as power plants and substations, it is used to monitor and manage power generation equipment, transmission equipment, distribution equipment, etc., collect equipment operation data in real time, analyze and process it, achieve optimal allocation and efficient use of energy, and improve the reliability and stability of the energy system.