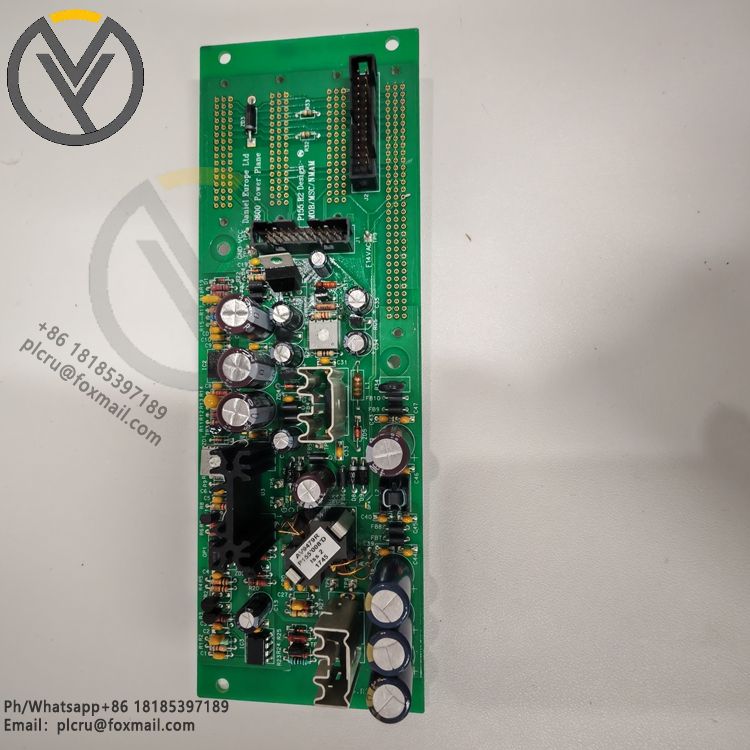

Emerson Ovation 5X00453G01 Remote Node Interface Module

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

The Emerson Ovation 5X00453G01 remote node interface module is a key component i

The Emerson Ovation 5X00453G01 remote node interface module is a key component in the Emerson Ovation system for communication and data interaction between remote nodes and the main system. The following is a related introduction:

Functional Features

Remote Communication: Supports connection with remote nodes through various communication networks, such as Ethernet, RS-485, etc., so that the main system can communicate with devices or subsystems located in different geographical locations.

Protocol Conversion: With the protocol conversion function, the communication protocol of the main system can be converted into a protocol that the remote node can understand, and vice versa, to ensure seamless communication between devices with different protocols. For example, the internal protocol of the Ovation system may be converted into common industrial communication protocols such as Modbus and Profibus to interact with third-party devices.

Data Processing and Cache: It can process the transmitted data, such as data format conversion, data filtering, data packaging, etc., to improve the efficiency and accuracy of data transmission. At the same time, it may also have a certain data caching capability to temporarily store data to avoid data loss when the network fails or the data transmission is busy.

Diagnosis and monitoring: Provides rich diagnostic functions, which can monitor the working status of the module itself and the communication status with remote nodes in real time, including the connection status of the communication link, the error rate of data transmission, etc. Detailed diagnostic information is provided to the operator through indicator lights, status registers or communication with the host computer, so as to facilitate timely discovery and resolution of communication faults.

Technical specifications

Communication interface: Usually equipped with a variety of communication interfaces, such as Ethernet interface (RJ-45), RS-485 interface, etc., to meet different communication network requirements. The Ethernet interface may support 10/100Mbps adaptive rate, and the RS-485 interface complies with relevant industrial standards and supports half-duplex or full-duplex communication mode.

Power supply requirements: Generally, it adopts 24V DC power supply, with good power supply stability and anti-interference ability to ensure reliable operation in industrial environment.

Operating temperature range: It adapts to a wide operating temperature range, usually -40℃ to 70℃, and can work stably in harsh industrial field environment.

Data transmission rate: The data transmission rate depends on the communication interface and protocol adopted. For example, the data transmission rate of the Ethernet interface can reach 100Mbps, and the transmission rate of the RS-485 interface can be configured within a certain range, such as 9600bps, 19200bps, etc.

Application scenarios

Industrial automation system: In large-scale industrial automation projects, it is used to connect field equipment, remote I/O modules, PLCs, etc. distributed in different areas to achieve centralized monitoring and distributed control of the entire system. For example, in the production process of petrochemical, electric power, metallurgy and other industries, the sensors, actuators and other equipment on site are remotely connected to the central control system, so that operators can monitor and operate the entire production process in real time in the control room.

Remote monitoring and management: Suitable for scenarios where remote equipment needs to be monitored and managed, such as remote pumping stations, remote substations, remote water treatment plants, etc. Through this module, managers can obtain the operating status and parameter information of the equipment in real time in the remote control center, and perform remote control and parameter adjustment to improve the management efficiency and reliability of the equipment and reduce maintenance costs.

System integration: In system integration projects, it serves as a bridge to connect equipment and systems from different manufacturers to achieve interconnection between heterogeneous systems. For example, the Emerson Ovation system can be integrated with other brands’ control systems, smart instruments, industrial computers and other equipment to achieve data sharing and collaborative work, thus building a complete industrial automation solution.