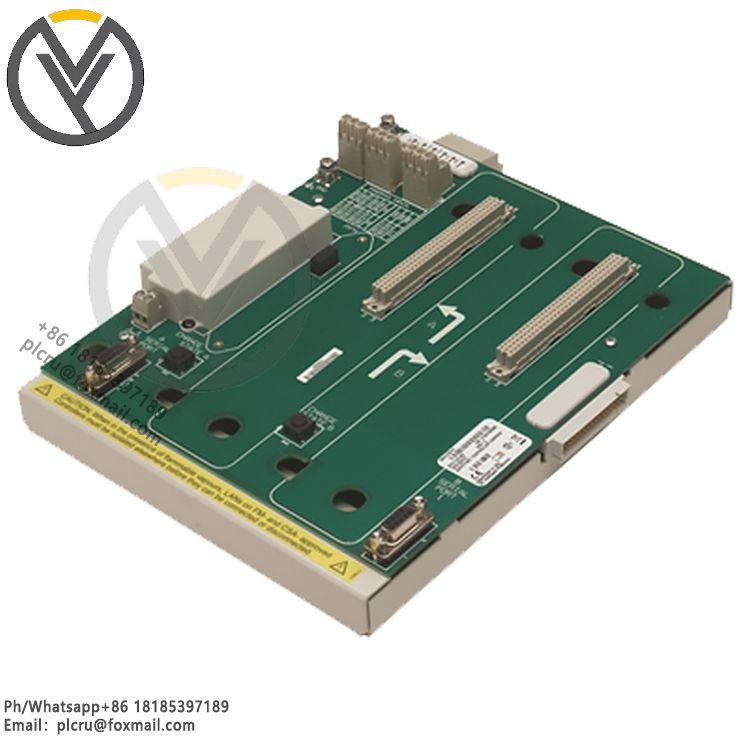

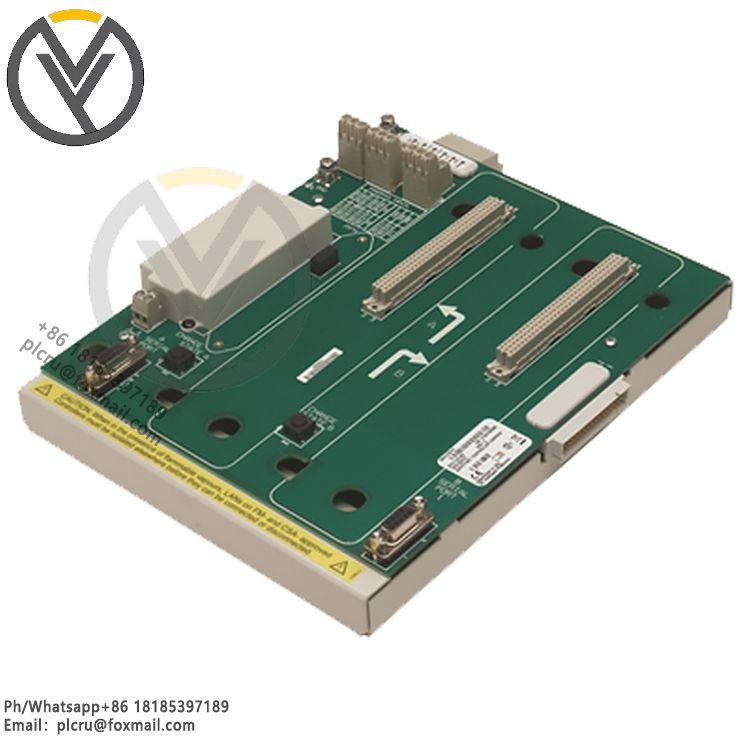

Emerson DeltaV 396572-02-2 Isolated Digital Output Module

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

Emerson DeltaV 396572 - 02 - 2 is an isolated digital output module in the Emers

Emerson DeltaV 396572 - 02 - 2 is an isolated digital output module in the Emerson DeltaV system. The following is its introduction:

Features

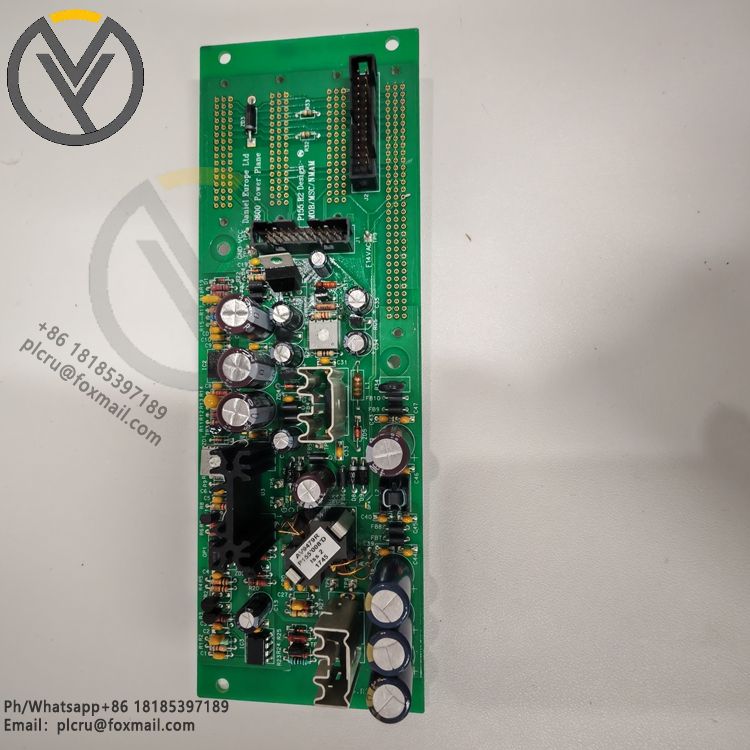

High isolation performance: Optoelectronic isolation technology is used to electrically isolate the output channel from other parts of the system, effectively preventing external electrical interference from entering the system, and also preventing the internal electrical noise of the system from affecting external devices, enhancing the stability and reliability of the system.

Multi-channel output: Usually multiple digital output channels are provided, which can control multiple external devices at the same time, such as relays, contactors, solenoid valves, etc., to achieve independent control of different devices, and improve the control ability and flexibility of the system.

Fault diagnosis function: It has fault diagnosis and status monitoring functions, and can monitor the status of the output channel in real time, such as whether the channel is working normally, whether short circuit or open circuit occurs, and timely feedback to the operator through indicator lights or system alarm information, which is convenient for quick positioning and troubleshooting.

Multiple output types: Supports multiple digital output types, such as transistor output, relay output, etc., to meet the driving requirements of different external devices. For example, transistor output is suitable for the control of high-speed switching signals, while relay output can be used to control devices with larger current and voltage.

Flexible configuration: It can be flexibly configured through the configuration software of the DeltaV system, and the parameters of the output channel can be set according to the actual application requirements, such as the logic level of the output signal, the action mode (normally open or normally closed), etc., to adapt to different control scenarios and process flows.

Technical specifications

Number of output points: Generally, there are 16 output channels, which can control 16 external devices at the same time.

Output voltage: Supports multiple output voltage ranges, such as 24V DC, 48V DC, etc., to match the power supply requirements of different external devices.

Output current: Each output channel can provide a certain driving current, usually between tens of milliamperes and several amperes, depending on the model and design of the module, which can meet the driving requirements of most common external devices.

Response time: The response time of the output signal is short, generally in milliseconds, which can quickly and accurately control the action of external devices and meet the control tasks with high real-time requirements.

Application scenario

Industrial automation control: In various industrial production processes, it is used to control the start and stop of motors, the opening and closing of valves, the operation of conveyor belts and other equipment to realize the automatic control and monitoring of the production process. For example, in chemical production, it controls the operation of the reactor's feed valve, discharge valve, and stirring motor; in steel plants, it controls the blast furnace's feeding system and the opening and closing of the furnace door.

Process control system: As part of the DeltaV system, it participates in complex process control applications, such as controlling process variables such as temperature, pressure, and flow. By cooperating with other input modules and controllers, it outputs control signals according to process requirements and adjusts the actions of the actuators to keep the process variables within the set range, ensuring the stability of the production process and the consistency of product quality.

Energy management system: In the field of energy production and distribution, it is used to control the start and stop of generator sets, the closing and disconnection of power grid switches, and the triggering of energy metering equipment. For example, in power plants, it controls the turbine's speed governor, the generator's excitation system, and other equipment; in substations, it controls the operation of high-voltage switches, knife switches, and other equipment.

Building automation system: In smart buildings, it is used to control lighting systems, air conditioning systems, elevator systems, security systems, and other equipment. For example, control the switching of lighting fixtures according to time or light intensity; control the operation mode of air-conditioning units according to temperature and humidity; control the floor call and operation direction of elevators; control the opening of door locks of access control systems, etc.