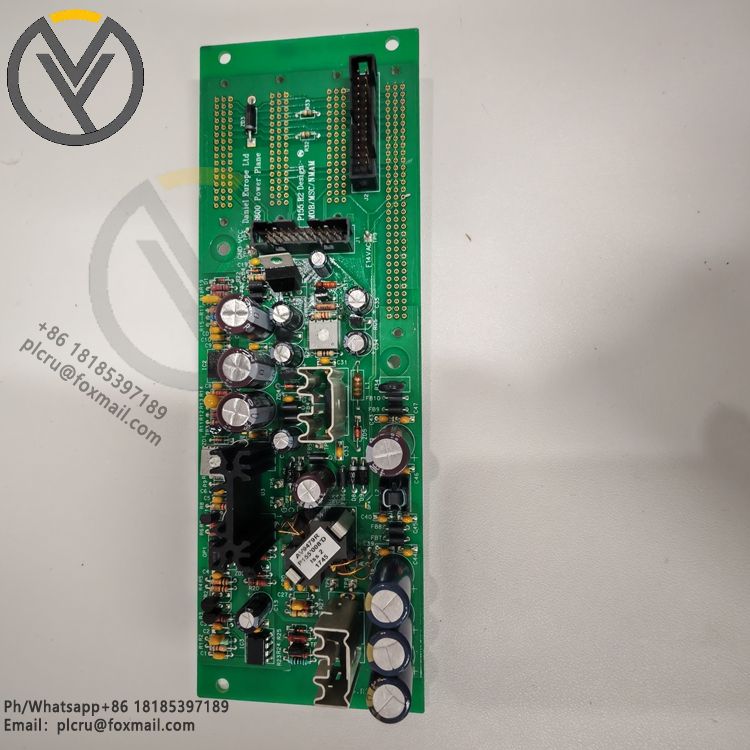

Emerson 396353-01-0 Process Automation Controller

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

Emerson's 396353-01-0 is a process automation controller. Here are some intr

Emerson's 396353-01-0 is a process automation controller. Here are some introductions about it:

Overview

This controller is one of the core devices in Emerson's process management system, designed to provide precise and reliable automation control for various industrial processes. It can receive signals from field sensors, perform logical operations and control algorithm processing, and send control instructions to actuators to achieve stable control of industrial processes.

Features

Powerful processing capabilities: It has a high-performance processor that can quickly process a large number of input and output signals and complex control algorithms, and can process multiple control loops at the same time to achieve precise control of multiple process variables.

Rich communication interfaces: It supports multiple communication protocols, such as HART, Profibus, Modbus, etc., and can easily communicate and integrate with other devices, such as data exchange and collaborative work with host computer monitoring systems, field instruments, actuators, etc.

High reliability design: It uses redundant technologies, such as redundant power supplies, redundant communication networks, etc., to ensure that the system can still operate normally in the event of a single point failure. At the same time, it has good anti-interference ability and can work stably in harsh industrial environments.

Flexible programming and configuration: Using specialized programming software, engineers can flexibly program and configure according to specific control requirements to implement various complex control strategies, such as PID control, fuzzy control, sequential control, etc.

Technical specifications

Number of input and output points: Usually there are multiple analog input and output channels and digital input and output channels. The specific number varies according to different models and configurations, which can meet the control needs of industrial processes of different scales.

Power supply requirements: Generally supports multiple power input methods, such as 24V DC, 110V AC or 220V AC, etc., to adapt to different on-site power supply conditions.

Operating temperature range: Generally - 40℃ to 85℃, which can adapt to temperature changes in most industrial environments.

Application scenarios

Petrochemical industry: Used to accurately control parameters such as temperature, pressure, flow, liquid level, etc. in the process of oil refining and chemical production to ensure the safety and stability of the production process and the consistency of product quality.

Power industry: In power plants, it can be used to monitor and control the operation of equipment such as boilers, steam turbines, generators, etc., to achieve automatic operation and optimized scheduling of units.

Pharmaceutical industry: In the pharmaceutical production process, the reactor, filling machine, packaging machine and other equipment are precisely controlled to meet the high precision and high reliability requirements of drug production and ensure that the drug quality meets the GMP standards.

Water treatment industry: It is used to automate the process flow of sewage treatment plants and water plants, such as the control of water pumps, valves, aeration equipment, etc., to achieve stable water quality and energy-saving operation.