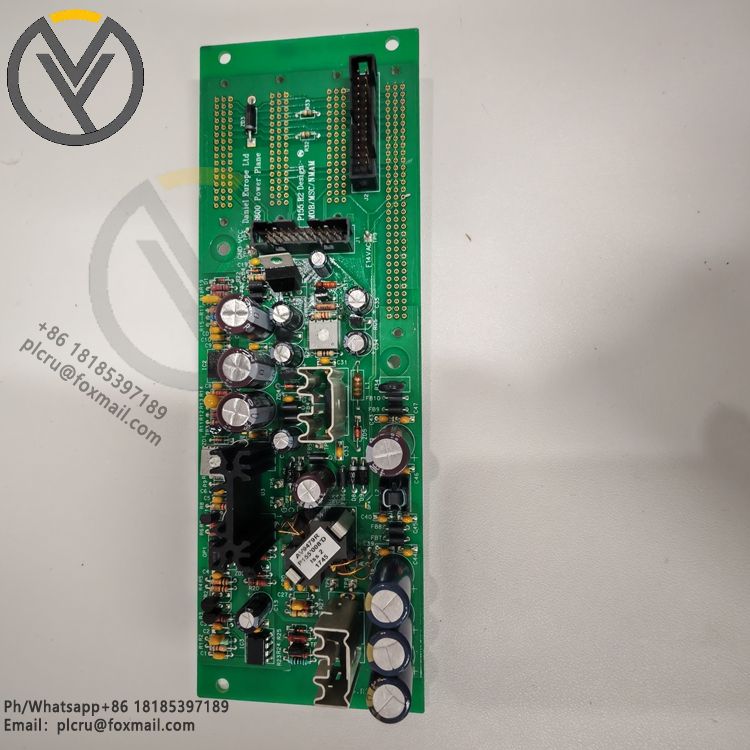

Emerson 396560-01-6 I/O Expansion Unit

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

Emerson's 396560-01-6 is an I/O expansion unit for the ControlWave Micro sys

Emerson's 396560-01-6 is an I/O expansion unit for the ControlWave Micro system. Here is a brief introduction:

Overview

This module enhances the input/output capabilities of the ControlWave Micro system by providing additional channels for field devices. It can connect various sensors, actuators, and field devices to increase the number of control and monitoring points of the system.

Features

Scalability: It can expand the I/O capacity of ControlWave Micro to meet the system's needs for more input and output points.

Modular design: It is easy to integrate seamlessly with the existing ControlWave Micro system and can be easily added or removed as system requirements change.

Strong compatibility: It is built specifically for the ControlWave Micro platform and follows its communication protocols and electrical standards to ensure stable and reliable connections and communications.

Technical specifications

Number of slots: There are 8 slots that can be used to insert different I/O modules to achieve various types of input and output functions, such as digital input, digital output, analog input, analog output, etc.

Power requirements: Powered by the ControlWave Micro system, the typical operating current is 2mA at 3.3V DC.

Communication method: Use a specific communication protocol to communicate with the ControlWave Micro interface, usually an Ethernet-based communication protocol such as TCP/IP.

Dimensions: 248mm×40mm×226mm, weight 0.45kg.

Working environment: Can work within a specific temperature and humidity range, adapt to general industrial environmental conditions, and the operating temperature range is usually -40℃ to +70℃.

Application scenarios

Process control: Used to monitor and control process variables such as temperature, pressure, flow, etc., and is widely used in production process control in industries such as chemical, petroleum, and natural gas.

Machine automation: Can manage the operation of machines and equipment, such as in automated production lines, CNC machine tools and other equipment, to achieve control and monitoring of motors, valves, sensors and other equipment.

Data acquisition: Collect data from field equipment for analysis and reporting, helping companies to optimize production, diagnose faults and control quality.