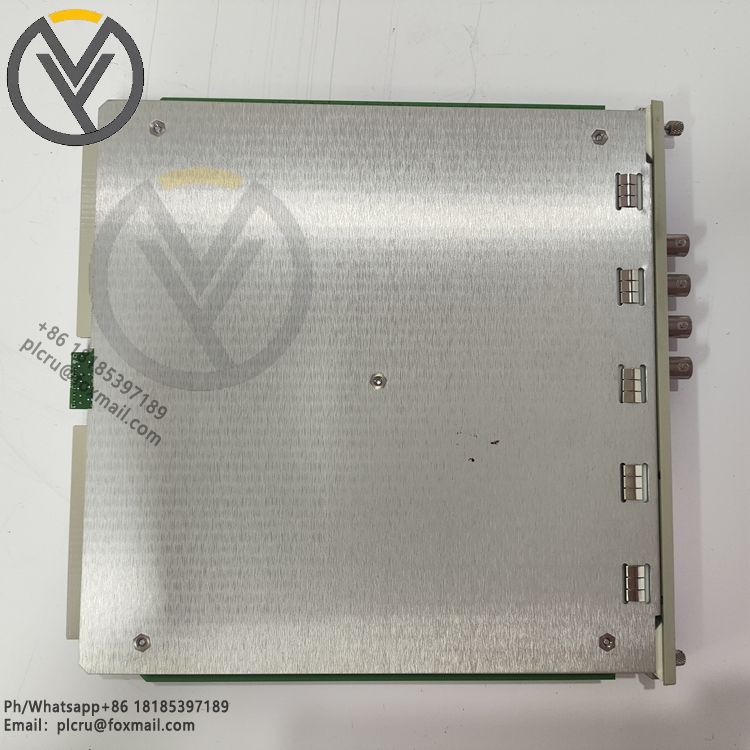

3500/42M 176449-02 Bently Nevada Preamplifier/Seismic Monitor

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

Bently Nevada 3500/42M 176449-02 is a high-performance preamplifier/seismic moni

Bently Nevada 3500/42M 176449-02 is a high-performance preamplifier/seismic monitor, mainly used for seismic monitoring and vibration analysis, and widely used in vibration monitoring and fault diagnosis of rotating machinery. The relevant introduction is as follows:

Main functions: It can receive input signals from proximity sensors and seismic sensors, and provide various vibration and position measurement data after processing the signals. Each channel can be programmed through the 3500 rack configuration software, and can perform functions such as radial vibration, thrust position, differential expansion, etc. It also supports user-programmable alarms, which can achieve mechanical protection by comparing the monitoring parameters with the configured alarm setpoints and triggering alarms if the threshold is exceeded.

Technical parameters:

Number of channels: 4 channels.

Input signal type: speed, acceleration, proximity signal, RPM, etc.

Input impedance: 10kΩ for standard I/O.

Frequency range: 0.5Hz to 20kHz.

Power supply: 18-32V DC, maximum power consumption 8W.

Measurement accuracy: With 24-bit resolution digital signal processing, the full channel measurement accuracy is ±0.5%.

Operating temperature: -40°C to + 85°C.

Product features: Dual redundant architecture ensures continuous operation during power conversion or network interruption. Automatic sensor verification and built-in 800-line FFT analysis function enable advanced diagnostics and early detection of mechanical failures in equipment such as turbines, compressors and pumps. In addition, the 176449-02 variant also specifically incorporates turbine blade path timing analysis, which is essential for detecting friction and blade fatigue in gas turbines.

Application areas: As part of the 3500 machinery protection system, it is mainly used for the protection of critical rotating equipment in the energy and process industries. It can be seamlessly integrated with the plant DCS through Modbus TCP/IP and OPC interfaces, complies with API 670 standards, and can operate reliably in harsh environments.