HONEYWELL 8C-TAIM01 Analog Input Module

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

The following is a detailed analysis of the HONEYWELL 8C-TAIM01 analog input mod

The following is a detailed analysis of the HONEYWELL 8C-TAIM01 analog input module, which is organized as follows in combination with technical specifications, features and practical applications:

I. Basic information

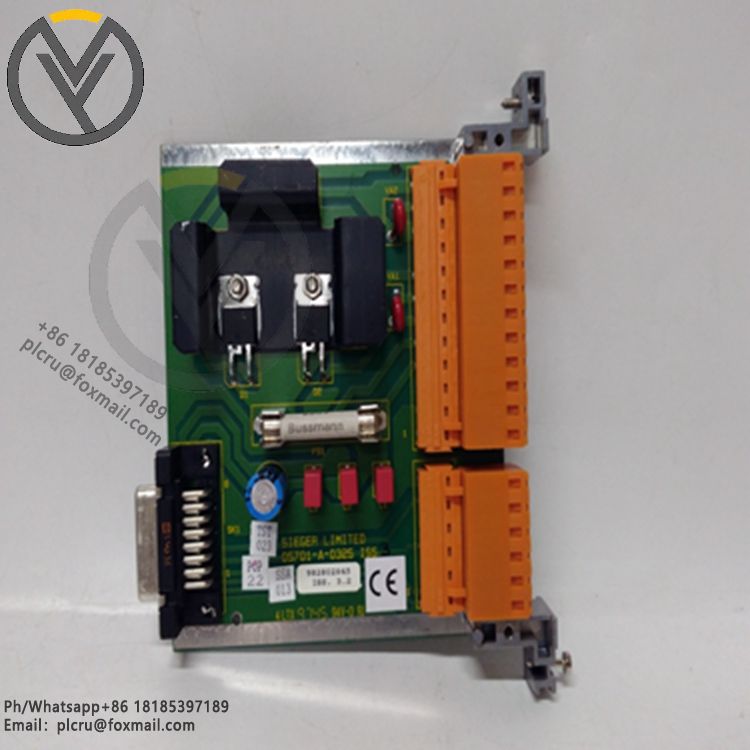

Brand model: Honeywell 8C-TAIM01 (corresponding spare part number: 51306999-175)

Product type: industrial analog input module, supporting multi-signal type acquisition

Series: Adapted to Honeywell ControlEdge™ PLC system, compatible with Experion® PKS distributed control system

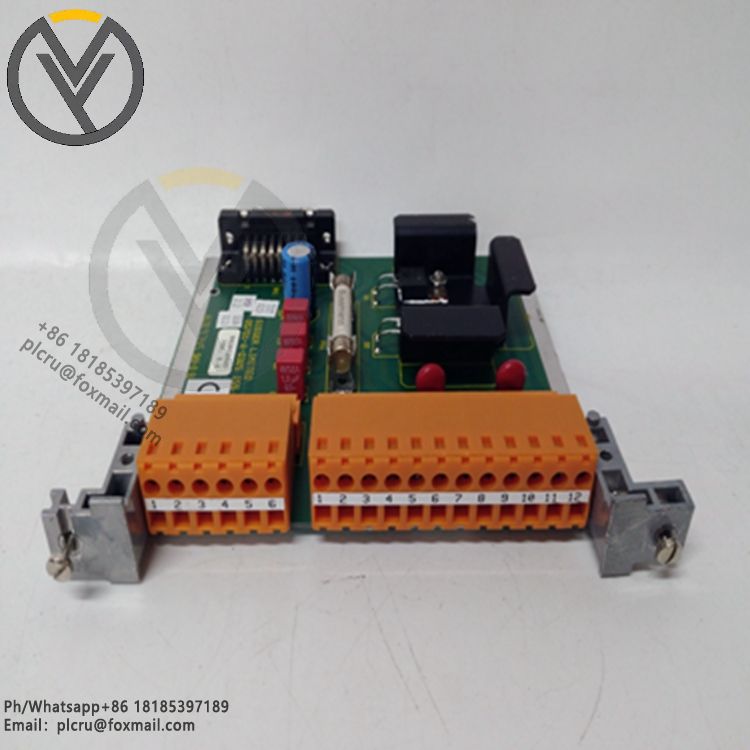

Number of channels: 16 channels (high-density design, saving space and wiring costs)

Input type:

Current: 0-20mA, 4-20mA (high-level transmitter signal)

Voltage: Supports customized range

Temperature: Thermocouple (such as K, J type), RTD (Pt100/500/1000, 2/3/4 wire)

Resolution: 16 bit (high-precision signal conversion to ensure process data accuracy)

Power supply and isolation: built-in isolation protection, anti-field interference; no external power supply required (non-intrinsically safe type)

Environmental adaptability: -40℃~85℃ wide temperature operation, CE, ROHS certification, suitable for harsh industrial environments

II. Core features

Multi-signal compatibility and flexible configuration

A single module supports multiple signals such as current, voltage, thermocouple, and RTD, adapts to different field instruments (such as pressure transmitters, temperature sensors), and reduces the number of spare parts. Channel parameters (such as filtering, calibration) can be customized through the Honeywell configuration tool.

High precision and reliability

16-bit ADC resolution, signal error <±0.1%, meeting the needs of high-precision scenarios such as chemical and pharmaceutical industries.

Built-in self-diagnosis function, real-time monitoring of channel faults (such as short circuit, open circuit), support for redundant configuration (optional), and improve system availability.

Industrial-grade design

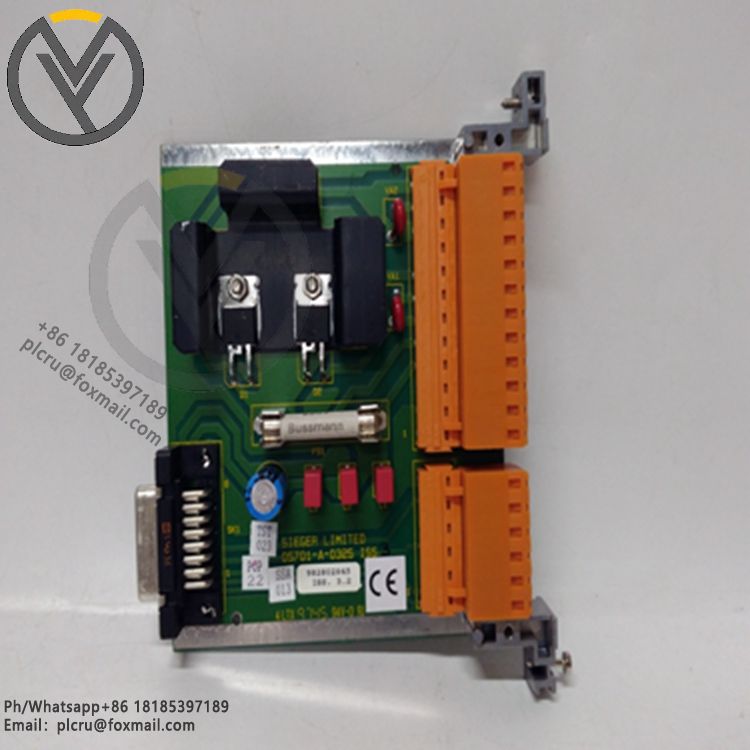

Compact structure (3cm×31.3cm×27.8cm), suitable for dense installation in control cabinets.

Anti-vibration and shock design, in line with industrial EMC standards, suitable for high-interference environments such as petroleum and metallurgy.

Seamless system integration

Directly communicate with ControlEdge PLC, data can be seamlessly connected to Experion PKS or third-party DCS, support Modbus and other protocols, and adapt to intelligent field instruments (must be debugged with SMART Field Communicator).

III. Working principle

Signal acquisition: 16 channels are independently sampled, supporting high-speed scanning up to 100ms/channel, and real-time capture of analog quantities such as temperature and pressure.

Signal conditioning: built-in hardware filtering and linearization algorithms, eliminating noise interference, automatic cold end compensation for thermocouples/RTD.

Digital conversion: 16-bit ADC converts analog signals into digital quantities (0-65535) and transmits them to the PLC controller through the backplane bus.

Fault handling: channel-level diagnosis (such as over-limit, disconnection), fault signals can be configured as preset values or alarms to ensure control continuity.

4. Typical application scenarios

Petrochemical: reactor temperature/pressure monitoring, distillation tower liquid level control, pipeline flow collection.

Pharmaceuticals and food: clean room temperature and humidity monitoring, fermentation tank pH value/dissolved oxygen concentration real-time analysis (in compliance with GMP record requirements).

Electricity and energy: boiler combustion temperature closed-loop control, solar panel array voltage/current monitoring.

Water treatment: sewage treatment plant water quality (COD, ammonia nitrogen) online detection, water pump inverter signal collection.

Intelligent manufacturing: automated production line sensor (displacement, force value) data collection, support MES system integration.

5. Selection and Adaptation

Compatible modules:

Digital output: CC-TDOR01 (relay/transistor output)

Analog output: CC-TAOX01 (4-20mA output)

Controller: ControlEdge PLC processor (such as CC-PROC01)

Summary

As the core module of Honeywell Industrial I/O, 8C-TAIM01 has the advantages of high density, multi-signal compatibility and high reliability, and is particularly suitable for complex scenarios that require refined data collection. Its deep integration with ControlEdge PLC and its support for redundancy and self-diagnosis make it an ideal choice for automation systems in industries such as petroleum, chemical, and pharmaceuticals.