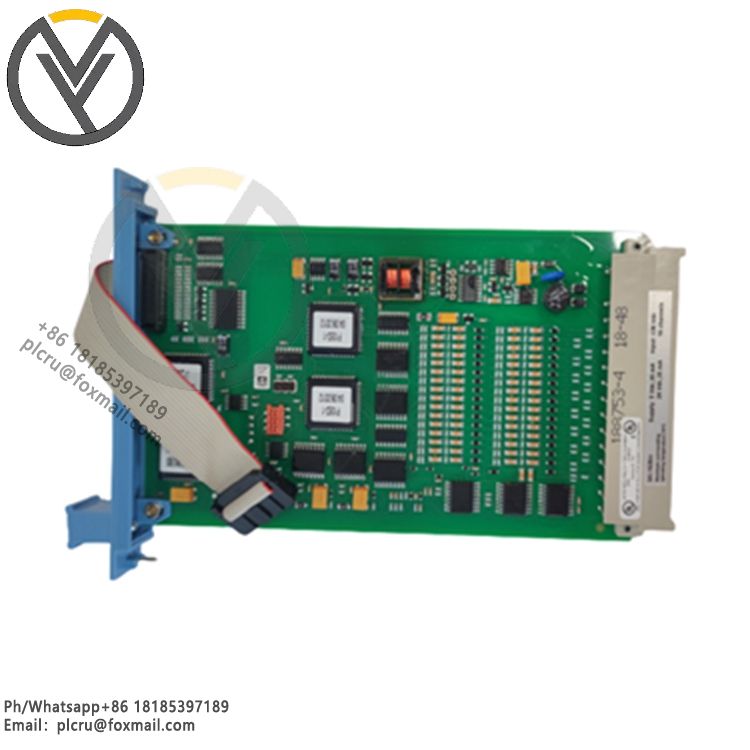

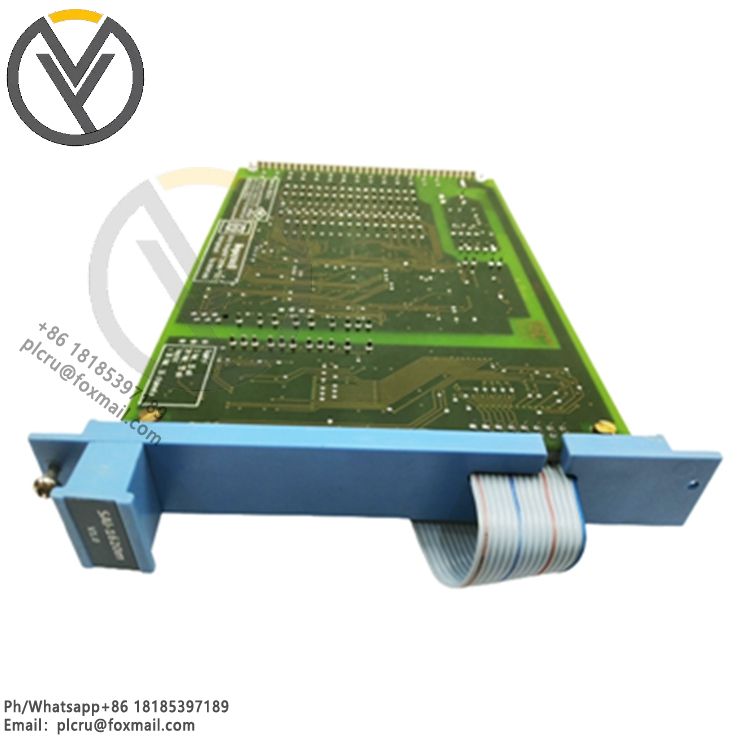

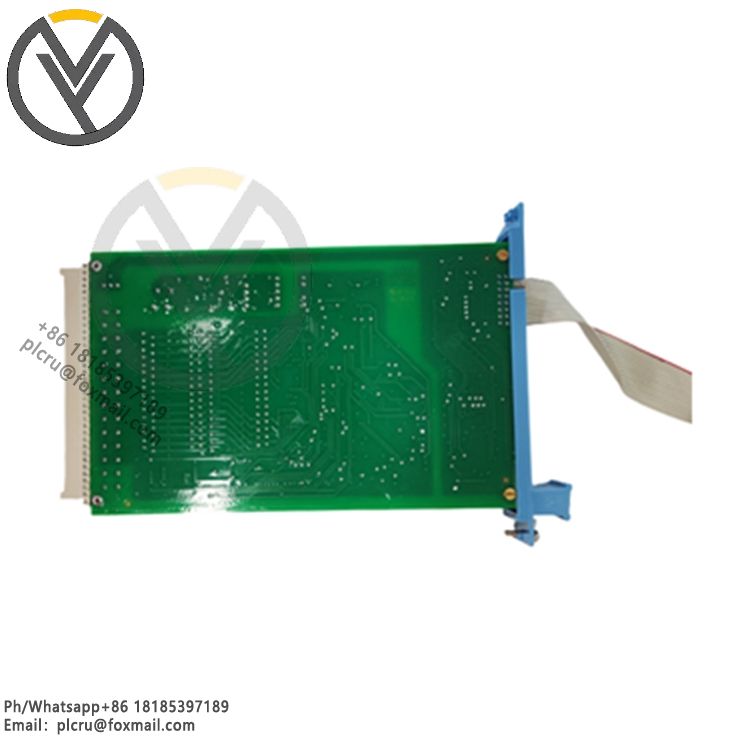

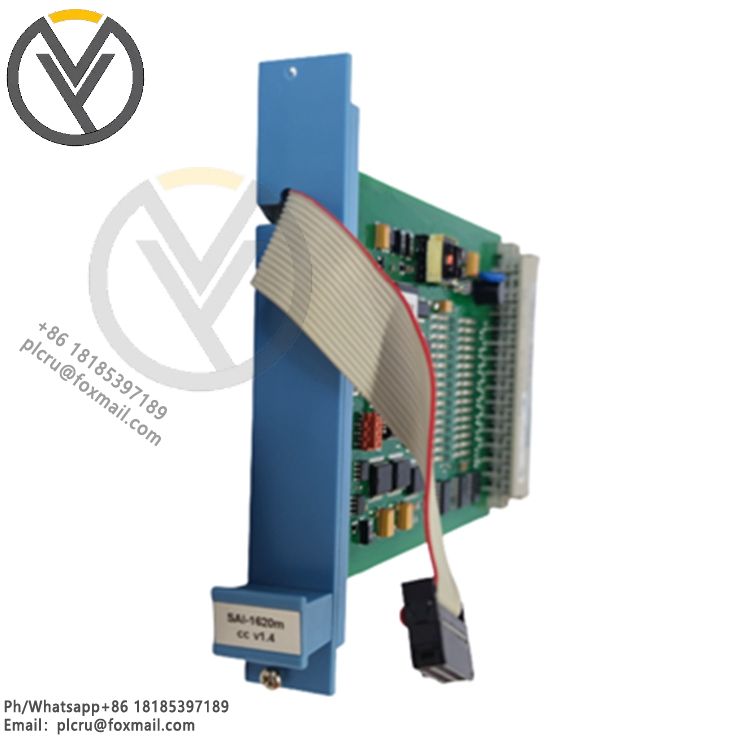

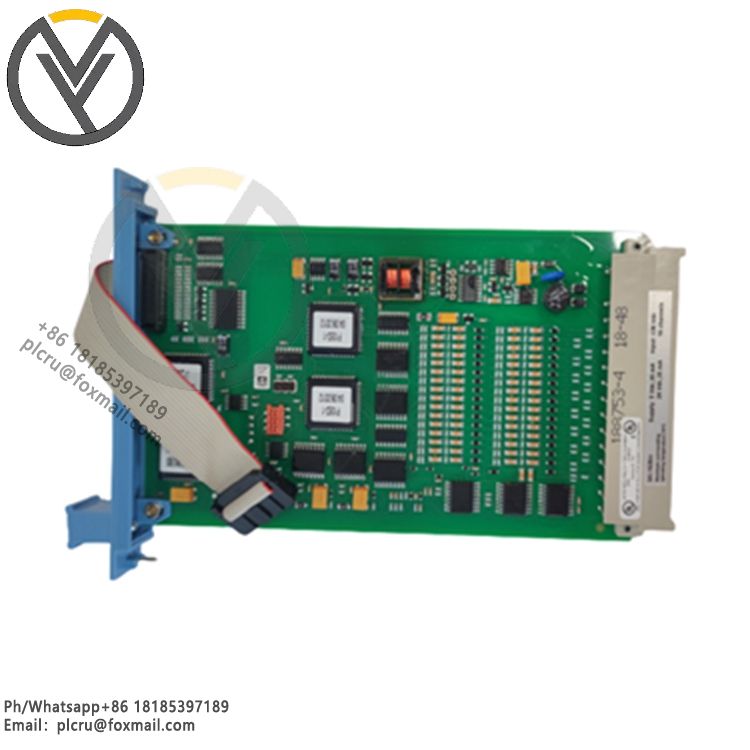

Honeywell 8C-TAIX61 51306977-175 Analog Input Module

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

Honeywell 8C - TAIX61 51306977 - 175 analog input module is a high-performance m

Honeywell 8C - TAIX61 51306977 - 175 analog input module is a high-performance module designed by Honeywell for industrial automation control systems. The following is a detailed introduction:

Basic information

Series: Usually belongs to Honeywell Experion PKS and other related control system series.

Number of channels: Generally has 8 analog input channels, can collect multiple analog signals at the same time, meet the needs of multi-parameter monitoring.

Input signal type: supports a variety of standard analog signal inputs, such as 4 - 20mA current signal, 0 - 10V or 0 - 5V voltage signal, etc., can be well adapted to various sensors and transmitters that output standard analog signals.

Resolution: Usually 16 bits, can achieve high-precision signal acquisition, can accurately convert analog signals into digital signals, help improve the overall accuracy of the control system.

Accuracy: has a high accuracy, generally up to ±0.1% or higher, can accurately measure and convert input analog signals, and provide reliable data support for industrial process control.

Isolation characteristics: There is usually good electrical isolation between channels and between channels and power supply. If the isolation voltage reaches 1500Vrms or above, it can effectively prevent the influence of external electrical interference on the measurement signal, enhance the module's anti-interference ability in complex electromagnetic environments, and improve the safety of the system.

Power supply requirements: Generally, 24VDC power supply is used, which has good stability and anti-power fluctuation ability.

Communication interface: Data transmission and communication with other devices of the control system are carried out through a specific communication bus, such as Profibus-DP, Modbus, etc. The specific interface type depends on the design and application scenario of the module.

Features and advantages

High-precision acquisition: 16-bit resolution and high measurement accuracy can accurately capture small changes in analog signals, which is suitable for industrial occasions with strict measurement accuracy requirements, such as key parameter monitoring in chemical, pharmaceutical, electronic manufacturing and other industries.

Multi-signal compatibility: Supports multiple analog signal type inputs, reduces the need to configure multiple modules due to different sensor signal types, improves the compatibility and flexibility of the system, and facilitates users to choose suitable sensors and transmitters according to actual needs.

Strong anti-interference ability: good electrical isolation and anti-interference design can work stably in harsh industrial electromagnetic environment, ensure the accuracy and reliability of the collected signals, reduce signal distortion and false alarms, and improve the stability and reliability of the system.

Flexible configuration: The module can be flexibly configured through software or hardware settings, such as range adjustment, filter parameter setting, alarm threshold setting, etc., to adapt to different industrial field environments and control requirements, and facilitate users to make personalized configurations according to actual applications.

Application scenarios

Industrial process monitoring and control: In the production process of chemical, petroleum, natural gas and other industries, it is used to monitor analog parameters such as temperature, pressure, flow, liquid level, and component analysis to provide accurate data for process control, realize precise control and optimization of the production process, and ensure production safety and product quality.

Energy management system: In the power system, it can be used to monitor parameters such as voltage, current, power, frequency, etc., to realize real-time monitoring and analysis of the operation status of the power grid, which helps to improve the stability and reliability of the power grid and optimize energy distribution and utilization efficiency. In the field of new energy power generation, such as solar and wind power generation systems, it is used to monitor the voltage, current, power of photovoltaic cells and the speed and power of wind turbines to achieve effective monitoring and management of new energy power generation equipment.

Intelligent buildings and HVAC systems: In intelligent buildings, it is used to monitor environmental parameters such as indoor and outdoor temperature, humidity, air quality, and illumination, as well as operating parameters such as chilled water temperature, flow, and pressure of air conditioning systems, to achieve comfortable control and energy management of the building environment, and improve the intelligence level and energy utilization efficiency of buildings.

Mechanical manufacturing and automated production lines: In the process of mechanical manufacturing, it is used to monitor the cutting force, vibration, temperature and other parameters of machine tools to achieve quality control of the processing process and equipment status monitoring, timely discover potential fault hazards, and improve the service life and production efficiency of equipment. In automated production lines, it is used to monitor related analog parameters such as material transportation and robot movement to ensure stable operation and efficient production of production lines.