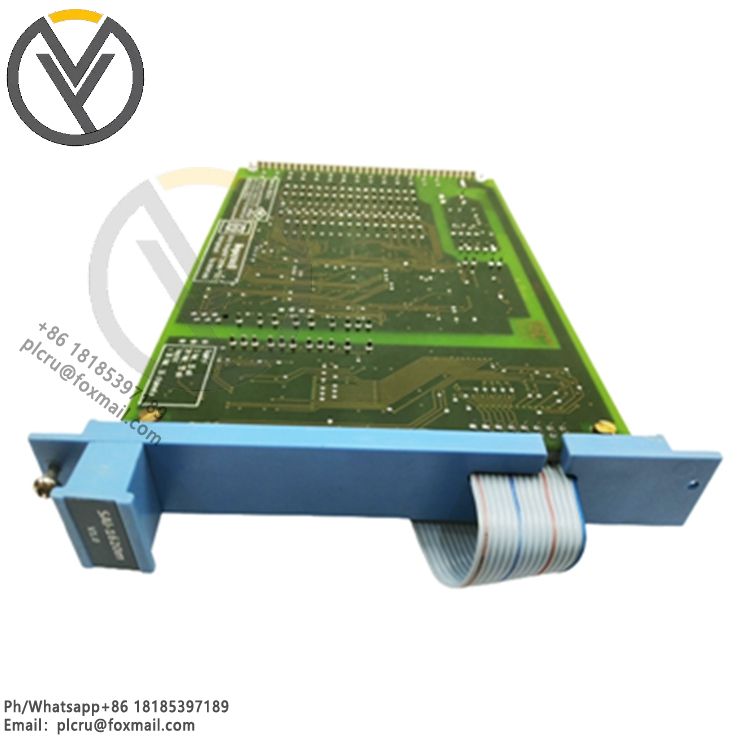

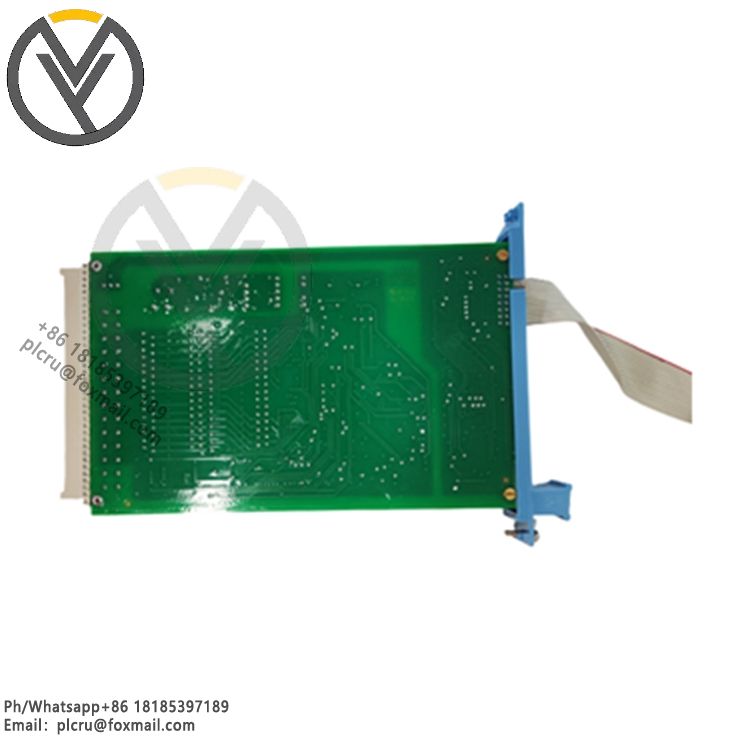

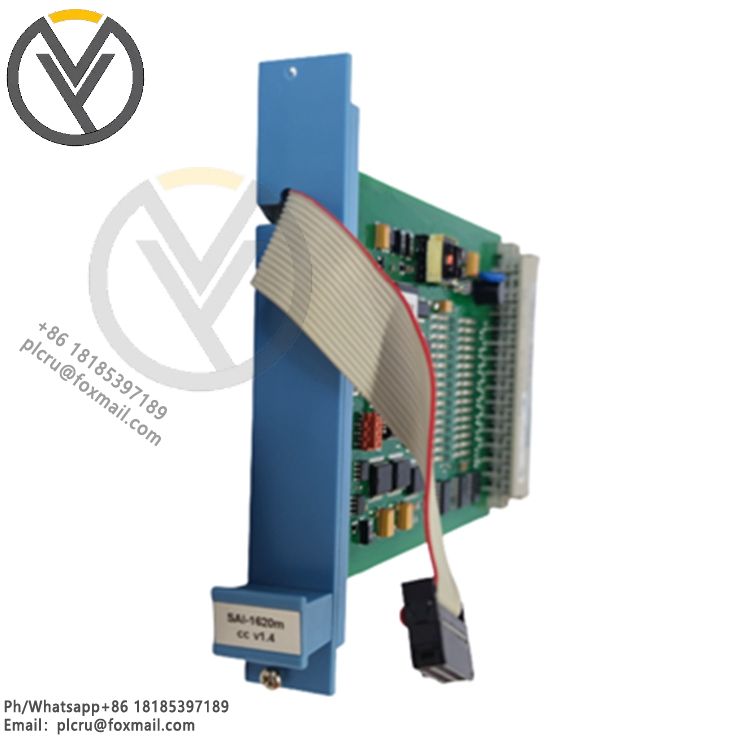

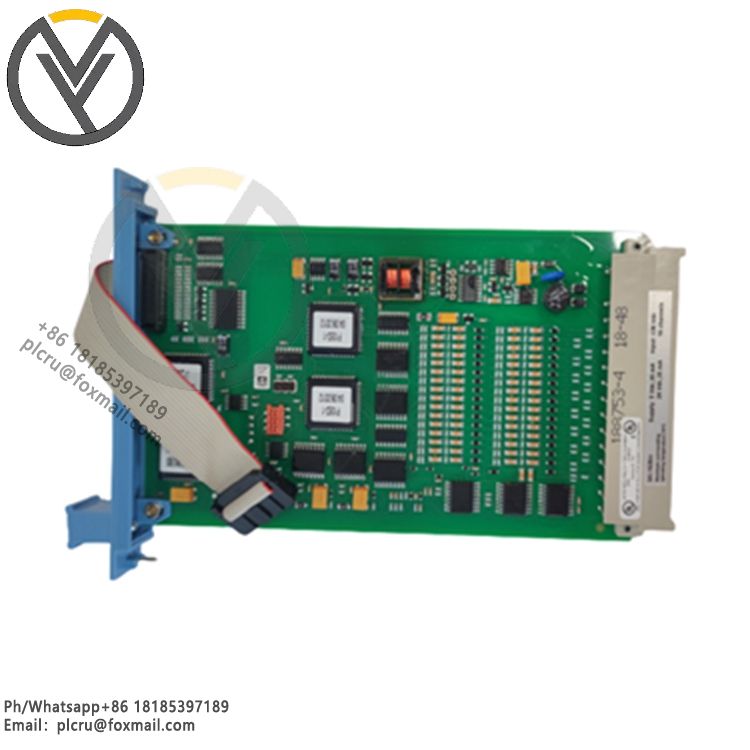

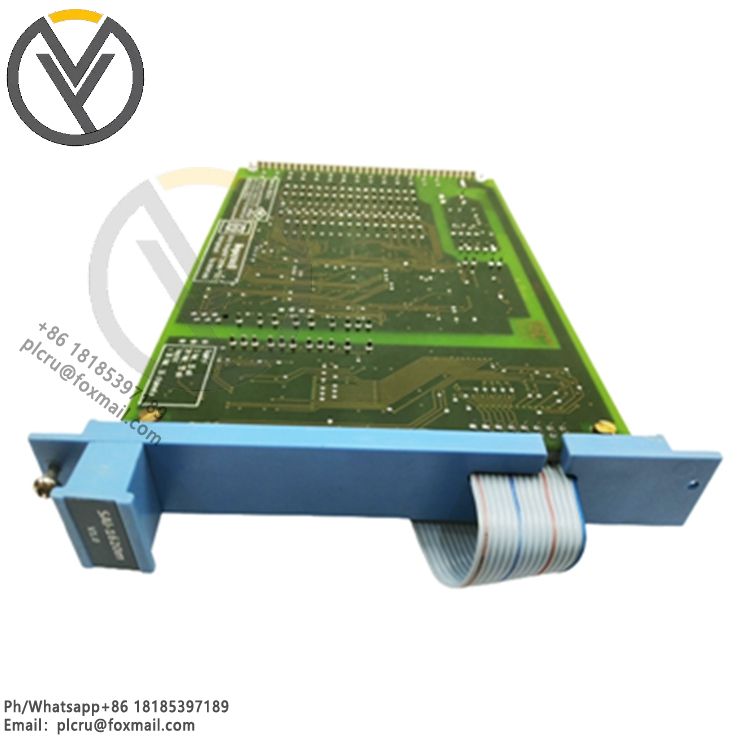

HONEYWELL 51401570-100 Keyboard Interface

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

Honeywell 51401570-100 Keyboard Interface Module OverviewProduct Positioning and

Honeywell 51401570-100 Keyboard Interface Module Overview

Product Positioning and Functions

The Honeywell 51401570-100 Keyboard Interface Module is a dedicated interface component for connecting keyboard devices in industrial control systems. It is mainly used to implement human-machine interaction (HMI) functions and supports operators to input commands, parameter settings or system control through the keyboard. It is designed to adapt to industrial environments, has high reliability and anti-interference capabilities, and is commonly used in distributed control systems (DCS), programmable logic controllers (PLCs) and other scenarios.

Technical Features

Interface Compatibility

Supports standard keyboard protocols (such as PS/2, USB or customized industrial interfaces), and can be adapted to industrial-grade keyboards or dedicated control keyboards.

May have an electrical isolation design to prevent external interference from affecting the control system and improve anti-electromagnetic interference (EMI) capabilities.

Signal Processing and Communication

Real-time analysis of keyboard input signals and conversion of commands into digital signals recognizable by the system to ensure the accuracy and timeliness of input responses.

Supports communication protocols (such as Modbus, EtherNet/IP, etc.) with the main control system (such as controller, host computer) to realize data transmission and command interaction.

Industrial-grade design

Wide operating temperature range (such as -20℃ to +60℃), adapting to harsh industrial environments (high temperature, dust, vibration, etc.).

With fault diagnosis function, it can monitor the interface status (such as connection interruption, signal abnormality) in real time, and feedback fault information through indicator lights or system logs.

Application scenario

Industrial control operation station

Connected to the control panel or operation table, it is used for operators to input control instructions, modify process parameters (such as temperature and pressure setting values), or view system status (such as alarm information, operation data).

Distributed control system (DCS)

As part of the human-computer interaction interface, it cooperates with monitors, mice and other devices to form a complete operation interface, supporting centralized monitoring and management of production processes (such as central control rooms in chemical and power industries).

Special equipment control

Adapts to industrial keyboards to realize specific functional operations, such as machine tool control panels, parameter configuration terminals of automated production lines, etc., to ensure the stability and safety of operations.

Installation and maintenance

Installation method: Supports rack-mount installation (such as DIN rail) or panel embedded installation, which is easy to integrate into the control cabinet or operating table.

Maintenance points: Regularly check the stability of the interface connection to avoid poor contact due to vibration; refer to the user manual for firmware upgrades to ensure compatibility with the main control system.