177230-00-01-CN | Bently Nevada Seismic Transmitter

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

Bently Nevada's 177230-00-01-CN seismic transmitter is a sensor used to moni

Bently Nevada's 177230-00-01-CN seismic transmitter is a sensor used to monitor equipment vibration. Here is a detailed introduction:

Overview: It is a reliable basic protection solution combined with the support and service of GE products. As a simple loop-powered device, it is easy to install and maintain, which can reduce training and service costs.

Features:

Good interface compatibility: It can be connected to control systems such as PLC, DCS and SCADA, and provides a fast learning curve for operation and maintenance through a familiar interface similar to connecting other PLC or control system inputs, and no on-site configuration or adjustment is required.

Function-rich: Includes self-test function and protected interface, supports a variety of interface cables, can provide accurate and repeatable data, uses a simple data format, and provides raw vibration signals for verification and analysis.

Safe and environmentally friendly: It meets EHS standards and adopts a safe and ergonomic design to support entry into hazardous areas.

Reliable design: It adopts a rugged design to ensure reliability and is an industry-standard 4-20mA loop-powered transmitter.

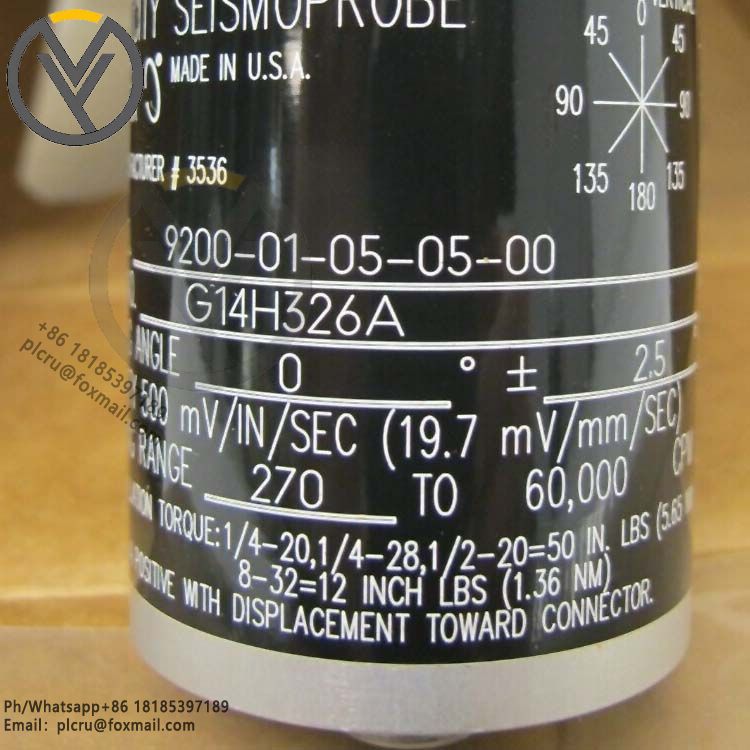

Technical Parameters:

Connector Type: 3-pin MIL-C-5015.

Humidity Tolerance: Up to 100% (non-submerged).

Sensitivity: 10.2mV/m/s² (100mV/g) ±20%.

Output Signal: Unbuffered voltage between Pin C and Pin B.

Full Scale Range: 147m/s² (15g) peak.

Frequency Range: 10Hz to 1kHz (600 to 60kcps) RMS.

Frequency Response: 2.5Hz to 10kHz ±10%.

Case Material: 316L Stainless Steel.

Operating Temperature Range: -40°C to +85°C.

Application: It is mainly used to measure the vibration of rolling element bearing boxes or mechanical housings. It automatically integrates the acceleration signal into a vibration signal and sends it to the controller, providing input for the PLC or control system in the factory asset status monitoring solution, helping users to better manage downtime, optimize maintenance plans and avoid unexpected catastrophic failures of mechanical assets. In addition, it also has a dynamic acceleration waveform output for advanced diagnosis.