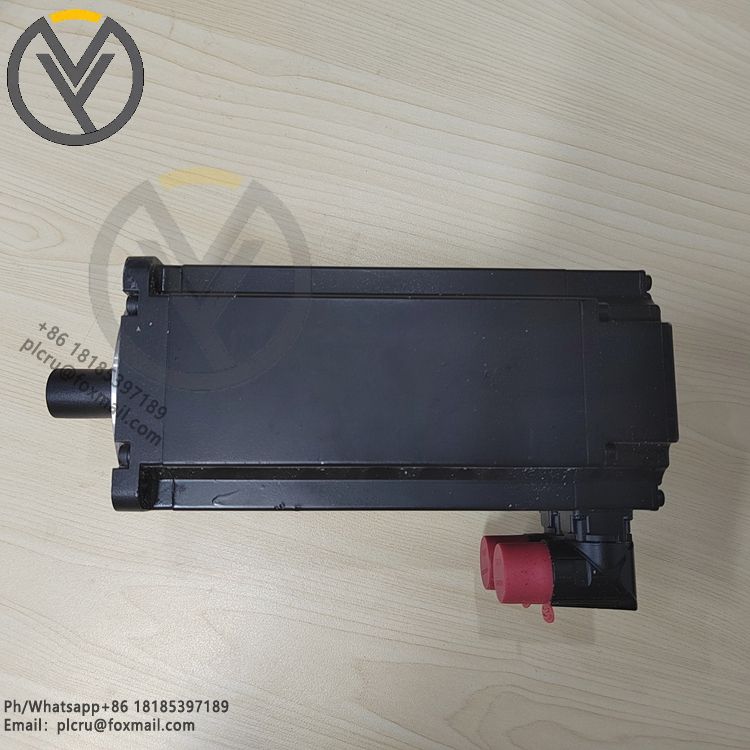

8LSA35.DA030S100-3 Servo Motor B&R

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

The B&R 8LSA35.DA030S100-3 is a high-performance synchronous servo motor from th

The B&R 8LSA35.DA030S100-3 is a high-performance synchronous servo motor from the ACOPOSmotor series, designed for high-precision motion control applications in industrial automation. The following are its key features and technical parameters:

I. Basic specifications

Rated parameters

Rated power: 3.0 kW

Rated speed: 3000 rpm

Stall torque: 9.55 Nm

Maximum torque: 28.6 Nm (3 times overload capacity)

Moment of inertia: 65.0×10⁻⁴ kg·m²

Number of pole pairs: 4

Power supply and voltage

Supply voltage: 3×380 - 480 V AC

Applicable drive: Recommended to use B&R ACOPOS P3 or ACOPOSmulti servo drive

II. Mechanical design

Structural features

Shaft type: smooth shaft with keyway (DIN 6885 - 1)

Mounting method: flange mounting (in accordance with IEC standard)

Protection level: IP65 (shaft end) / IP64 (housing)

Cooling method: forced air cooling (built-in fan)

Physical parameters

Dimensions: length 214 mm, flange size 130×130 mm

Weight: approx. 12.5 kg

Shaft extension size: 28 mm diameter, 8 mm key width

III. Feedback system

Encoder type:

Standard Hiperface DSL absolute encoder (23-bit single-turn, unlimited multi-turn)

Support EnDat 2.2 or Sin/Cos encoder (optional)

Functional features:

Position accuracy up to ±0.01°

Automatic identification of motor parameters (stored by encoder)

Support dynamic braking and safety functions (such as STO safe torque shutdown)

IV. Performance advantages

Dynamic response

High power density design, small size, high torque

Fast acceleration and deceleration capability (maximum acceleration > 10,000 rad/s²)

Low cogging torque (<1% rated torque), smooth operation

Reliability

High temperature resistant insulation material (F grade, 155°C)

Built-in PT100 temperature sensor to prevent overload

Bearing life > 20,000 hours (continuous operation)

Application scenarios

Applicable to high-precision positioning systems, robot joints, packaging machinery, printing equipment, etc.

Supports synchronous operation and electronic gear functions

V. Compatibility

Drive system: seamlessly integrated with B&R ACOPOS series servo drives

Control system: supports industrial Ethernet protocols such as Powerlink and Ethernet/IP

Software tools: Parameter configuration and debugging can be performed through Automation Studio