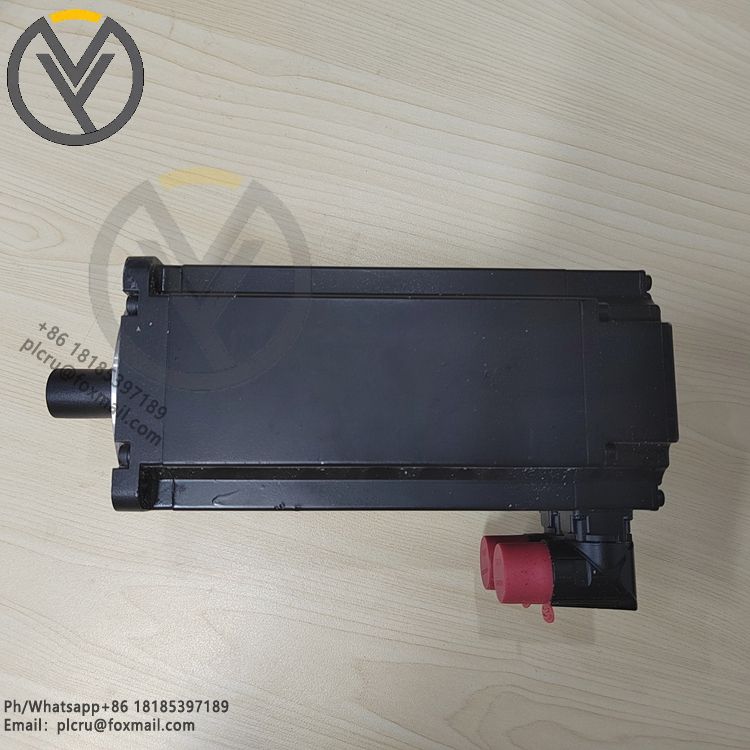

B&R 8LSA57.DB045S000-3 Synchronous Motor

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

B&R 8LSA57.DB045S000-3 is a synchronous motor from B&R, belonging to the 8LS ser

B&R 8LSA57.DB045S000-3 is a synchronous motor from B&R, belonging to the 8LS series, which is a compact, highly dynamic servo motor with high efficiency. The following is its relevant information:

Technical parameters:

Rated power: usually at the level of several kilowatts, please refer to the product manual for details, and the power of some motors in the same series can reach about 2000W.

Rated voltage: 200 - 600V.

Rated current: about 60A.

Rated speed: can reach about 5000rpm.

Rated torque: The torque range is generally 2 - 200N・m, and the specific value is related to factors such as the operating status of the motor.

Encoder type: Generally, a rotary encoder can be configured, and there may be a variety of options such as Heidenhain EnDat encoders, and multi-turn encoder versions are also available.

Protection level: It has protection levels such as IP55/56/65, which can adapt to certain dust and water splash environments.

Product features:

High-precision control: It can be equipped with a high-resolution encoder to ensure smooth operation and precise positioning of the motor. The multi-turn encoder version does not require additional sensors and zeroing operations, which is convenient for system debugging and operation.

High reliability: It uses a battery-free absolute encoder and does not require maintenance. The motor bearings have been optimized, and some can be equipped with reinforced bearings to withstand high radial forces. The built-in dual temperature monitoring system can effectively protect the motor windings.

Compact design: The motor has a compact structure and light weight, can adapt to installation environments with limited space, and is easy to integrate into various mechanical equipment.

Convenient debugging: The built-in parameter chip stores relevant mechanical and electrical information. The driver can automatically identify the motor and determine the current limit and control parameters, saving debugging time and workload.

Application areas: It is suitable for industries such as tobacco, new energy, and automobile manufacturing. It can be used in situations such as material handling and positioning in new energy production equipment, and the drive of robot arms in automobile production lines, which require high-precision position control, speed control, and torque control.