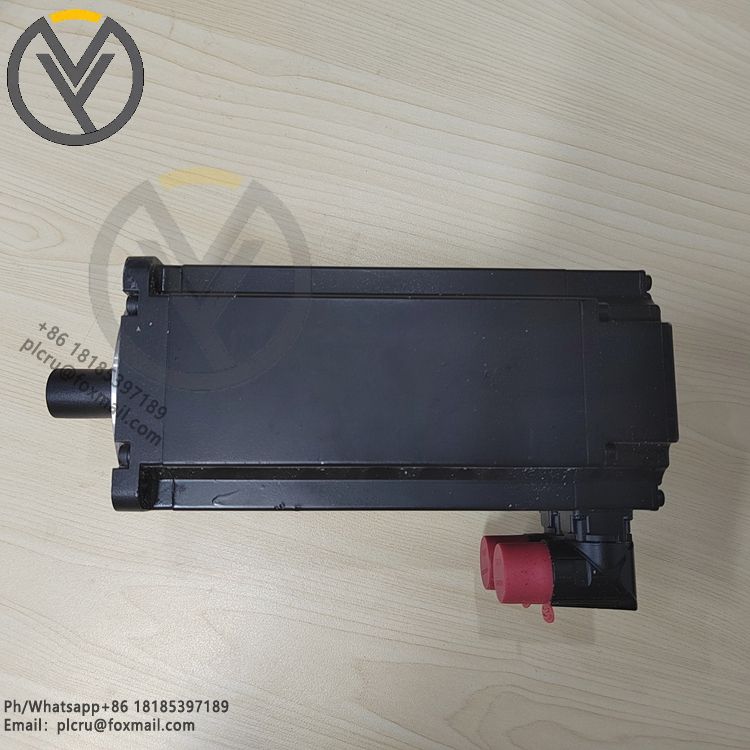

B&R 80SD100XD.C0XX-21 ACOPOSmicro stepper motor module

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

B&R 80SD100XD.C0XX - 21 ACOPOSmicro stepper motor module is a high-performance m

B&R 80SD100XD.C0XX - 21 ACOPOSmicro stepper motor module is a high-performance motion control module launched by B&R Automation Technology Co., Ltd. The following is some introduction about it:

Features

Compact design: It has a small size, which can save space in the control cabinet and is suitable for automation equipment and systems with limited space.

High-precision control: It supports the subdivision drive technology of stepper motors, which can subdivide the basic step angle into smaller angles to achieve higher-precision position control. For example, the common 1.8-degree basic step angle can be subdivided into 0.18 degrees or even smaller, so as to meet the application with demanding requirements for position accuracy.

Flexible configuration: Parameters can be configured through software, which is convenient for users to set the motor's operating parameters according to different application requirements, such as step angle, speed, acceleration, deceleration, etc. It can also adapt to various types and specifications of stepper motors and has strong versatility.

Multiple communication interfaces: usually equipped with multiple communication interfaces, such as CANopen, EtherCAT, etc., which can be easily connected with B&R controllers or other brands of control systems to achieve efficient data transmission and real-time control, and easy to integrate into various automation control systems.

Diagnosis and protection functions: With complete diagnostic functions, it can monitor the working status of the module and motor in real time, such as detecting abnormal conditions such as overcurrent, overvoltage, overheating, motor blocking, etc., and promptly issue alarm signals, and take corresponding protection measures to protect the module and motor from damage, and improve the reliability and stability of the system.

Application scenarios

Automated production line: In automated production lines such as electronic manufacturing and automotive parts production, it is used to control the movement of robot arms, the positioning of material handling equipment, the movement of various fixtures and tooling on the production line, etc., to achieve precise position control and motion synchronization, and improve production efficiency and product quality.

CNC machine tools: In CNC machining centers, lathes, milling machines and other CNC machine tools, this module can control the feed of the workbench, the positioning and movement of the tool, etc., to ensure the accuracy and surface quality of part processing, and realize complex processing technology.

Medical equipment: In the fields of medical imaging equipment, surgical robots, medical equipment testing equipment, etc., it can be used to accurately control the moving parts inside the equipment, such as the movement of the scanning platform, the operation of the robotic arm, etc., to provide high-precision position control for medical diagnosis and treatment.

3D printing equipment: In the 3D printing process, it is responsible for controlling the movement of the print head, the lifting of the printing platform, etc., to achieve precise layered printing and ensure the accuracy and quality of the 3D printed model.