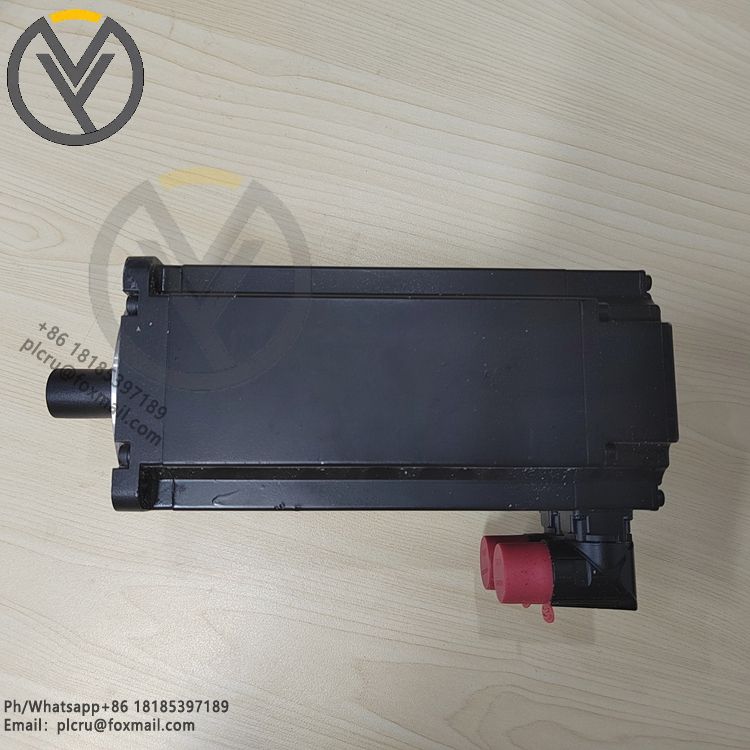

B&R 80MPH4.500S000-01 2-phase hybrid stepper motor

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

B&R 80MPH4.500S000 - 01 is a two-phase hybrid stepper motor from B&R. Here is an

B&R 80MPH4.500S000 - 01 is a two-phase hybrid stepper motor from B&R. Here is an introduction to it:

Working Principle

The hybrid stepper motor combines the advantages of permanent magnet and reactive stepper motors. There are multi-phase windings on the stator, permanent magnet materials on the rotor, and multiple small teeth on the rotor and stator to improve the stepping accuracy. When the stator winding is fed with an electric pulse signal that changes in a certain order, the stator magnetic field changes, and the rotor rotates according to the change in the stator magnetic field to align with the stator teeth, thereby converting the electric pulse into mechanical motion.

Features

High precision: The step angle of the two-phase hybrid stepper motor is generally 1.8 degrees. Through the driver subdivision technology, the step angle can be further subdivided, which can achieve higher positioning accuracy and is suitable for occasions with high requirements for position control accuracy.

High torque output: It has the advantages of both permanent magnet and reactive stepper motors, with a large output torque, which can meet the needs of some applications that require a large driving force and can drive a certain load to operate.

Good dynamic performance: It can quickly respond to changes in control signals, show good performance during start, stop and speed change, and can adapt to frequent start and stop and fast-changing motion control requirements.

High reliability: As a well-known automation brand, B&R usually pays attention to quality in product design and manufacturing, using high-quality materials and advanced processes to make the motor have high reliability and stability, and can operate stably for a long time in industrial environments.

Application scenarios

Automated production line: For example, in electronic equipment manufacturing production lines, it is used to control operations such as handling, positioning and assembly of precision parts; in automobile manufacturing production lines, it can be used for joint drive of robot arms and precise delivery of parts to ensure high precision and high efficiency of the production process.

CNC machine tools: It undertakes tasks such as feed movement of the workbench, positioning and feeding of the tool, realizes high-precision part processing, and ensures the accuracy and surface quality of the processing size.

Medical equipment: For example, in medical testing equipment, it is used to accurately control the position of the detection probe or sample platform; in surgical robots, it provides precise motion control for the joints of the robotic arm, which helps to improve the accuracy of the operation.

3D printing equipment: Control the movement of the print head and the lifting of the printing platform to achieve precise layered printing and ensure the accuracy and quality of the 3D printed model.