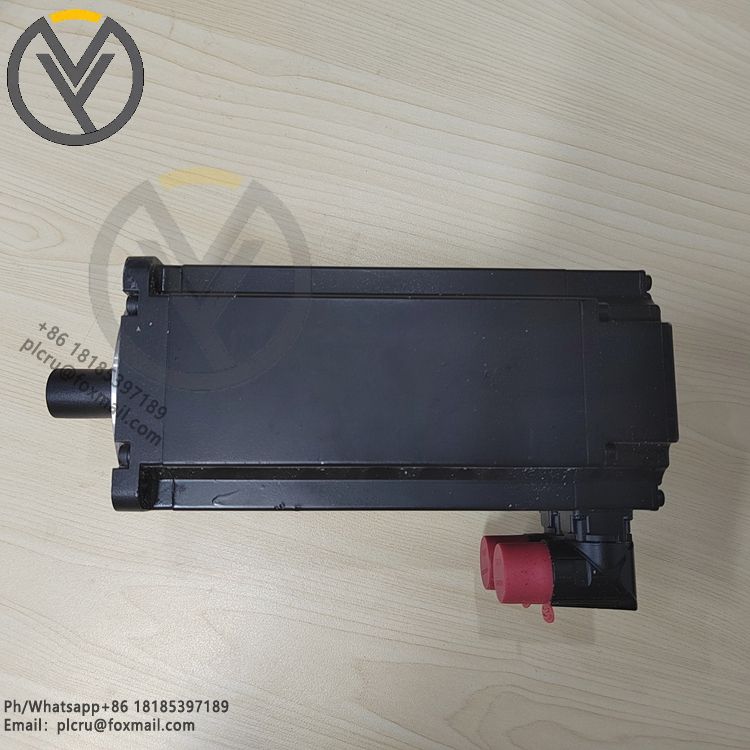

B&R 5AC901.LSD3-00 Link module

The B&R 5AC901.LSD3 - 00 is a link module designed for specific industrial automation applications. Here are its possible features and applications:

- Features

- Communication Interface: It is likely to be equipped with various communication interfaces such as Ethernet, PROFIBUS, or POWERLINK. These interfaces enable seamless connection with other devices in the industrial automation network, facilitating efficient data transmission and communication between different components.

- Protocol Support: It may support standard industrial communication protocols like Modbus TCP, CANopen, or B&R's own proprietary protocol. This ensures compatibility and interoperability with a wide range of industrial devices, allowing the module to exchange data and commands with other devices according to the specific protocol rules.

- High - Speed Data Processing: With advanced microprocessors and signal - processing circuits, the module can handle high - speed data transmission and processing. It can quickly receive, analyze, and forward data, meeting the real - time requirements of industrial automation systems. For example, in a high - speed production line, it can promptly transmit the control commands and status information of each device to ensure the coordinated operation of the entire production line.

- Reliability and Stability: Industrial - grade components and a robust design are employed to ensure the module's reliable operation in harsh industrial environments. It has high resistance to electromagnetic interference, shock, and vibration, and can work stably in high - temperature, high - humidity, and dusty conditions. In addition, it may have built - in redundant backup and fault - diagnosis functions to improve the reliability and maintainability of the system.

- Applications

- Automotive Manufacturing: In automotive production lines, the 5AC901.LSD3 - 00 link module can connect various automation devices such as robots, conveyor belts, and welding machines. It enables the seamless integration and coordinated operation of these devices, improving production efficiency and quality. For example, it can transmit the position and movement commands of the robot to ensure accurate welding and assembly operations.

- Food and Beverage Industry: In food and beverage production plants, this module can be used to connect sensors, actuators, and controllers. It helps monitor and control the production process, such as regulating the filling volume of beverages, controlling the temperature and humidity of the production environment, and ensuring the stability and safety of the production process.

- Textile Industry: In textile mills, the 5AC901.LSD3 - 00 link module can be applied to the control system of textile machinery. It can connect spinning machines, weaving machines, and other equipment, realizing the automation and intelligentization of textile production. It can also monitor the operation status of the equipment in real time and promptly send out fault alarms to improve production efficiency and reduce downtime.