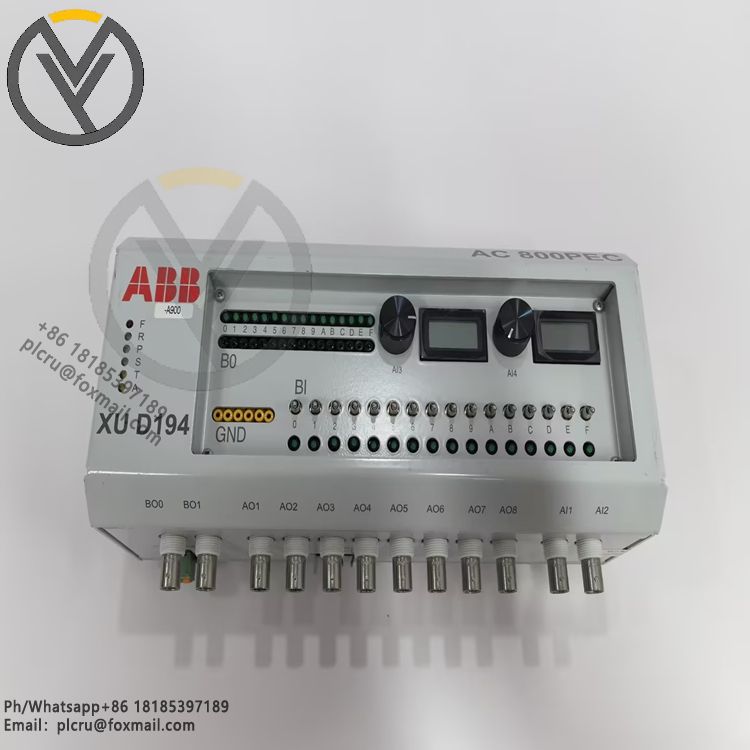

ABB XUD194 3BHE018137R0001 AC800PEC High performance controller module

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

ABB XUD194 3BHE018137R0001 AC800PEC high-performance controller module is a high

ABB XUD194 3BHE018137R0001 AC800PEC high-performance controller module is a high-end product in the field of ABB industrial automation. It is designed for the integration of high-speed process control and low-speed industrial automation tasks, and is suitable for complex scenarios such as power electronics, energy, and transportation. The following is a summary of its core information:

1. Core positioning and functions

High-speed + low-speed control integration:

Integrate the high-speed control of power electronic equipment (such as 100 microsecond cycles) and the low-speed process control of traditional PLCs (such as I/O signal processing) to meet the high-precision requirements of large power converters, drives, and power generation and distribution systems.

Modular architecture:

Support standard DIN rail installation, connect a wide range of I/O modules (analog/digital input and output, fieldbus, etc.) through the optical fiber S800 module bus, up to 36 bidirectional links, and flexibly expand distributed control systems.

Industrial-grade reliability:

No forced cooling design, adapt to harsh environments, the processor uses a 750 MHz 64-bit RISC chip + floating-point unit, supports redundant configuration (such as dual fiber links), and ensures continuous operation.

2. Programming and configuration

Multi-tool support:

Control Builder M: complies with the IEC 61131-3 standard, supports programming languages such as ladder diagrams and structured text.

MATLAB/Simulink: Automatic code generation through a dedicated toolbox (Simulink Coder required), supports real-time simulation (External Mode), and is suitable for algorithm development and debugging.

System integration:

Seamlessly connected to the ABB 800xA system, supports OPC communication, is compatible with third-party Anybus-S fieldbus modules, and is suitable for complex industrial networks.

3. Hardware specifications

Core module:

Processor module: Integrated AnyIO interface (including Anybus-S slot), supports CEX communication expansion bus.

Backplane (AC800PEC BP): Install power supply, processor and optical fiber/communication module, support hot swap.

I/O compatibility:

Support voltage (0-10V), current (4-20mA) signals, adapt to industrial sensors such as temperature, pressure, flow, etc., and compatible with high-precision analog input modules such as ABB DSAI130A.

Power supply and environment:

Support AC 220V or DC 24V power supply, operating temperature - 20°C to + 60°C, suitable for wide temperature industrial scenarios.

4. Typical application scenarios

Power electronics: real-time control of inverters and excitation controllers (such as ABB Unitrol series).

Energy and utilities: process monitoring and protection of power stations and substations (such as REF543 relay coordination).

Transportation traction: high-speed power regulation of rail transit and electric vehicle charging facilities.

Industrial automation: high-precision synchronous control of production line equipment (such as Yalong YL-15A training device).

5. Operation and expansion

Engineering management: Program backup, remote download/upload, and fault recovery are supported through engineering workstations (such as SIMATIC Manager-level tools).

Redundant design: Support dual fiber links or multi-controller collaboration to improve system fault tolerance (need to be combined with 800xA architecture).

Market supply: Spot goods are commonly found on industrial spare parts platforms (such as Alibaba and Chinese suppliers), with a unit price of about 2,200 yuan. Pay attention to model matching (such as XUD194 corresponds to 3BHE018137R0001).

Summary

AC800PEC XUD194 module is the core product of ABB's "Control IT" strategy. With the three advantages of high-speed control, modular expansion, and multi-tool programming, it has become a benchmark for "high performance + high flexibility" in industrial automation. It is suitable for scenarios that require the integration of power electronics high-speed algorithms and traditional PLC logic, such as upgrade needs in new energy, high-end manufacturing and other fields.