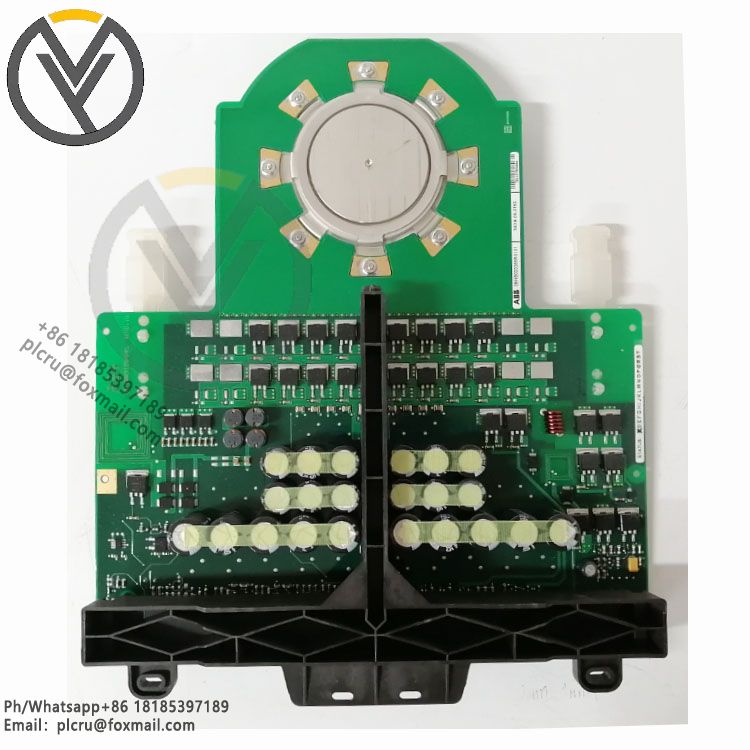

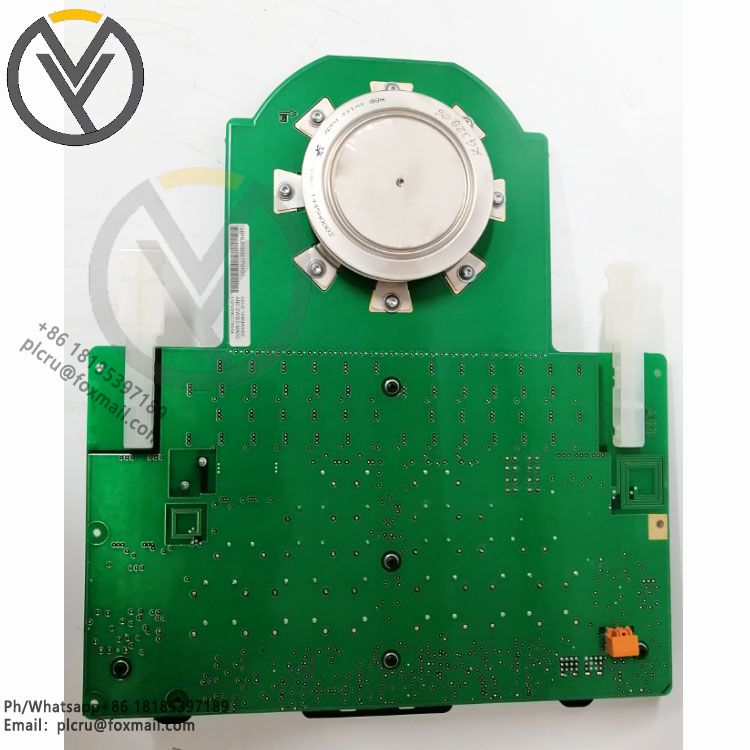

3BHB012961R0001 | 5SHX 2645L0002 ABB IGCT MODULE

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

The core working mechanism of the IGCT module is as follows:Conduction phase: Af

The core working mechanism of the IGCT module is as follows:

Conduction phase: After the gate applies a positive trigger signal, the PNPN structure inside the IGCT forms positive feedback and enters a low-resistance conduction state with strong current carrying capacity.

Shutdown phase: The gate current is quickly extracted through the drive circuit, so that the carriers inside the device are quickly recombined, and the anode current is forced to be shut down, avoiding the "holding effect" of traditional thyristors. The shutdown process does not require a complex absorption circuit.

IV. Application scenarios

High-voltage inverter (MV Drive)

Used to drive large industrial motors (such as fans, water pumps, compressors), and achieve energy-saving control through variable frequency speed regulation, which is commonly used in metallurgy, mining, petrochemical and other fields.

Static synchronous compensator (STATCOM)

Dynamically adjust reactive power in the power system, stabilize the grid voltage, and improve the power factor.

Renewable energy grid-connected converter

Such as medium and high voltage grid-connected devices for wind power and photovoltaics, realize DC-AC conversion and access the grid.

Rail transit traction system

Traction converters used in high-speed rail and subways provide high-power power conversion and support train starting, speed regulation and braking.

V. Module structure and advantages

Integrated design: Integrate IGCT devices, drive circuits, and protection components into the same module to reduce wiring complexity and improve system reliability.

Heat dissipation optimization: The bottom of the module usually uses a metal substrate (such as a copper substrate) and is matched with a water cooling plate to achieve efficient heat dissipation and adapt to long-term full-load operation.

Reliability guarantee: Built-in overvoltage and overcurrent protection mechanisms, support fault diagnosis functions (such as feedback of module operation status through status pins).

VI. Installation and maintenance points

Electrical connection

Ensure that the anode (A), cathode (K), and gate (G) are firmly connected to avoid overheating caused by excessive contact resistance.

Heat dissipation system

The water cooling system needs to ensure flow and water quality (such as deionized water) to avoid scaling that affects heat dissipation efficiency; the air cooling module needs to ensure sufficient fan air volume.

Drive matching

A drive unit matching ABB (such as the 5SHX series dedicated drive board) must be used to ensure that the timing and amplitude of the trigger signal meet the requirements.

Regular inspection

Check whether the module has cracks or discoloration, measure the insulation resistance between each pin (power off and discharge), and monitor the switch waveform through an oscilloscope to see if it is normal.