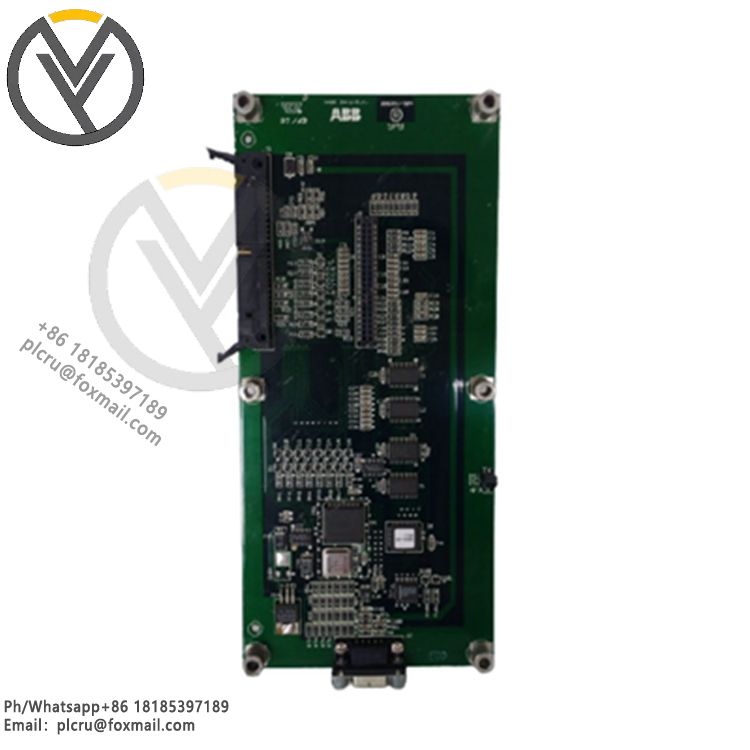

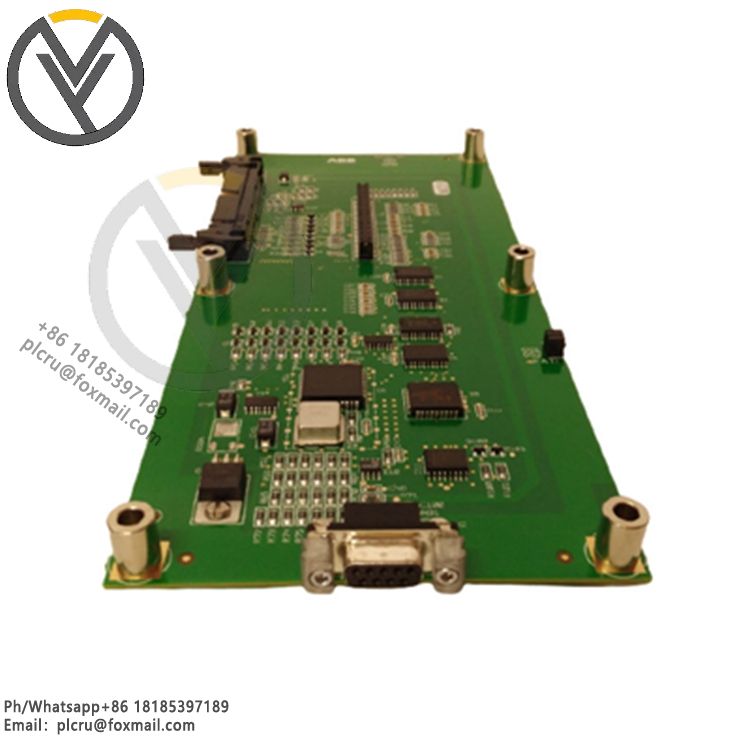

ABB 3ASC25H204 DAPU 100 Control Board I/O

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

ABB's 3ASC25H204 DAPU 100 control board I/O is an important part of its cont

ABB's 3ASC25H204 DAPU 100 control board I/O is an important part of its control system for input and output signal processing. Here is some information about its features and applications:

Features

Good versatility: It may use universal I/O technology. The same I/O point can be configured into multiple signal types through software, such as analog input (AI), analog output (AO), digital input (DI), digital output (DO), etc., which reduces the workload of design selection and improves the flexibility of the system.

Strong signal processing capability: It can process signals of various types and different precisions. For example, analog signals may have high resolution and can accurately collect and output analog data; digital signals can quickly and accurately respond to changes in switch status to achieve precise control of equipment.

With diagnostic functions: Generally, there will be comprehensive self-diagnostic functions, and any errors can be reported to the processing operator station through the LED indicators on the front of the module, as well as alarm information and indicators, which is convenient for quick location and troubleshooting. Fault inputs can be disabled and simulated through manual input, and fault outputs will be automatically disabled or driven to a predetermined safe state.

Strong anti-interference ability: All modules meet the highest standards of electromagnetic immunity, can work stably in complex industrial electromagnetic environments, meet the requirements of EU Directives 2014/30/EU and 2014/35/EU, and ensure the accuracy and stability of signal transmission.

Application scenarios

Industrial automation production line: used to connect various sensors (such as temperature sensors, pressure sensors, position sensors, etc.) and actuators (such as motor drivers, solenoid valves, relays, etc.) in the production line to achieve real-time monitoring and precise control of the production process, and ensure efficient and stable operation of the production line.

Process control system: In process control in chemical, petroleum, metallurgical and other industries, analog signals of process parameters such as temperature, pressure, flow, etc. can be collected, and control signals can be output to the corresponding actuators to achieve automated control of the production process and ensure product quality and production safety.

Robot control system: As an interface between the robot controller and external devices, it can connect various sensors (such as visual sensors, force sensors, etc.) and end effectors (such as grippers, spray guns, etc.) of the robot to achieve information interaction and motion control between the robot and the surrounding environment, so that the robot can accurately perform various tasks.