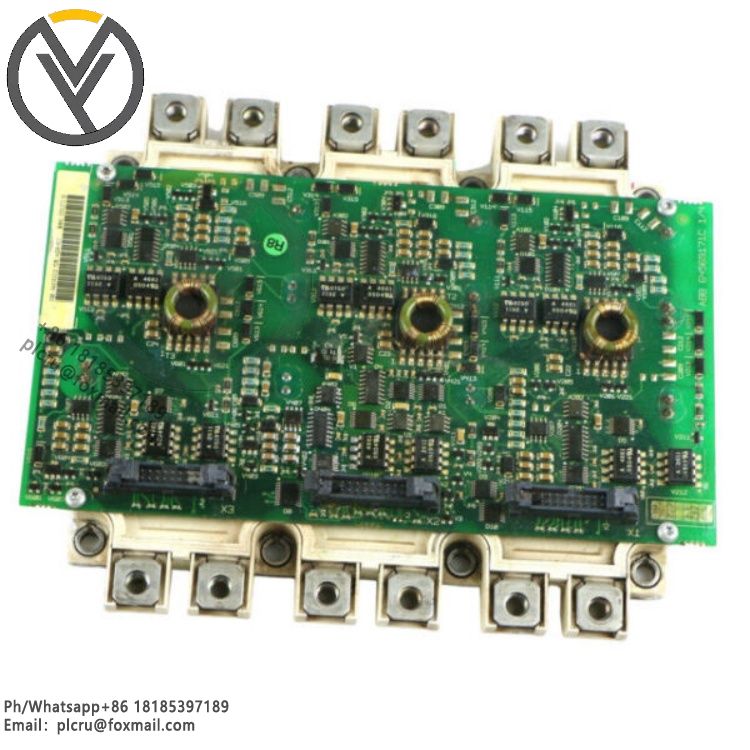

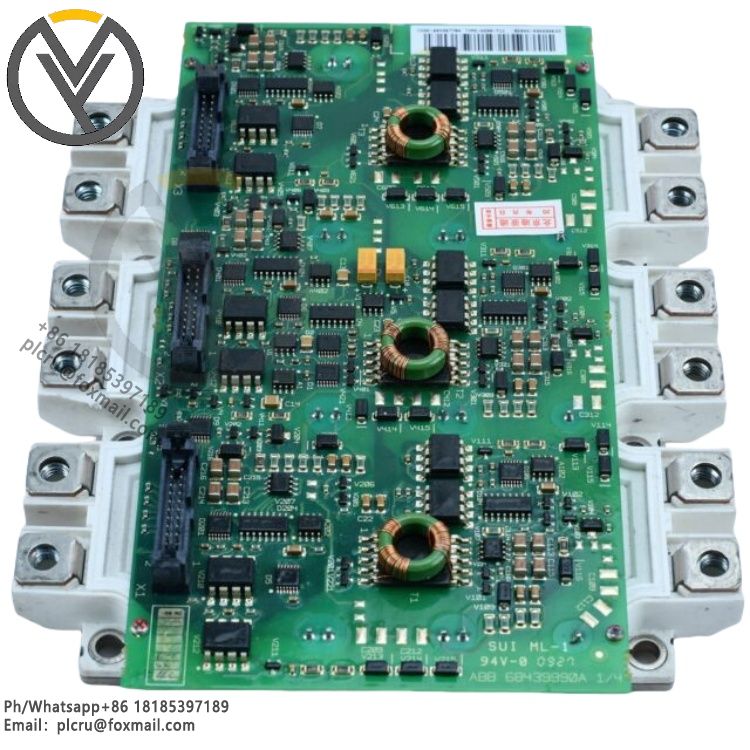

ABB 3ADT313900R1501 Control Board Main Module

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

The ABB 3ADT313900R1501 control board main module is a key component in the ABB

The ABB 3ADT313900R1501 control board main module is a key component in the ABB control system. Here is some information about it:

Function

Core control: As the main module of the control board, it undertakes the core control task of the entire system operation, coordinates the work between various sub-modules and external devices, and ensures that the system runs in an orderly manner according to the preset logic and instructions. For example, in an industrial automation production line, it can control all aspects of the production process, such as material transportation, equipment processing, quality inspection, etc., so that the entire production line can run efficiently and stably.

Signal processing and calculation: It has powerful signal processing and calculation capabilities, and can receive input signals from various sensors, such as temperature, pressure, flow, position and other signals, and analyze, process and calculate these signals. According to the preset control algorithm, the processed signal is converted into a control instruction and output to the corresponding actuator, such as a motor, valve, drive, etc., to achieve precise control of the controlled object.

Communication and data interaction: It supports multiple communication protocols, such as Profibus, Modbus, Ethernet/IP, etc., and can communicate and interact with other devices or systems at high speed and reliably. Through the communication interface, it can upload the operating status and parameter information of the local device to the host computer monitoring system, and receive the control instructions, parameter settings and other information sent by the host computer to realize remote monitoring and management, which is convenient for operators to centrally monitor and remotely operate the system.

Features

High reliability: It adopts redundant design, fault-tolerant technology and high-quality electronic components, and can operate stably in harsh industrial environments. It has strong anti-interference ability and long mean time between failures. For example, in industrial sites with high temperature, high humidity and strong electromagnetic interference, it can maintain stable performance, ensure the normal operation of the system, and reduce production interruptions and losses caused by equipment failure.

High-performance processing capability: Equipped with high-performance processors and rich memory resources, it can quickly process a large number of input and output signals and complex control algorithms to achieve real-time control and precise adjustment of the system. For example, in application scenarios with high requirements for real-time and accuracy, such as high-speed motion control and multi-axis linkage control, it can respond quickly and accurately control to ensure the motion accuracy and stability of the equipment.

Flexibility and scalability: It has rich interfaces and flexible configuration functions, which can be easily connected and integrated with different types of sensors, actuators and other equipment. At the same time, it can expand and upgrade functions according to different application requirements, and support new control tasks or process flows through software configuration or adding modules, protect users' initial investment, and meet changing production needs.

Application scenarios

Industrial automation field: widely used in various industrial automation production lines, such as automobile manufacturing, electronic manufacturing, food and beverage processing, packaging and printing and other industries, used to control robots, conveyor belts, processing equipment, testing equipment, etc. on the production line, to achieve automatic control and optimization of the production process, improve production efficiency and product quality.

Power system: In power plants, substations and other power systems, it is used to monitor and control generators, transformers, switchgear, etc., to achieve stable operation and automatic management of the power system. For example, the excitation control of the generator, the reactive compensation control of the power system, the comprehensive automation control of the substation, etc., are inseparable from the precise control and coordination of the control board main module.

Process control industry: In process control industries such as chemical, petroleum, metallurgy, and water treatment, it is used to collect and process various process parameters, such as temperature, pressure, flow, liquid level, etc., and adjust the actuator according to the preset control strategy to maintain the stable operation of the production process and ensure product quality and production safety. For example, it plays an important role in temperature control of chemical reactors, pressure control of oil pipelines, and liquid level control of sewage treatment plants.