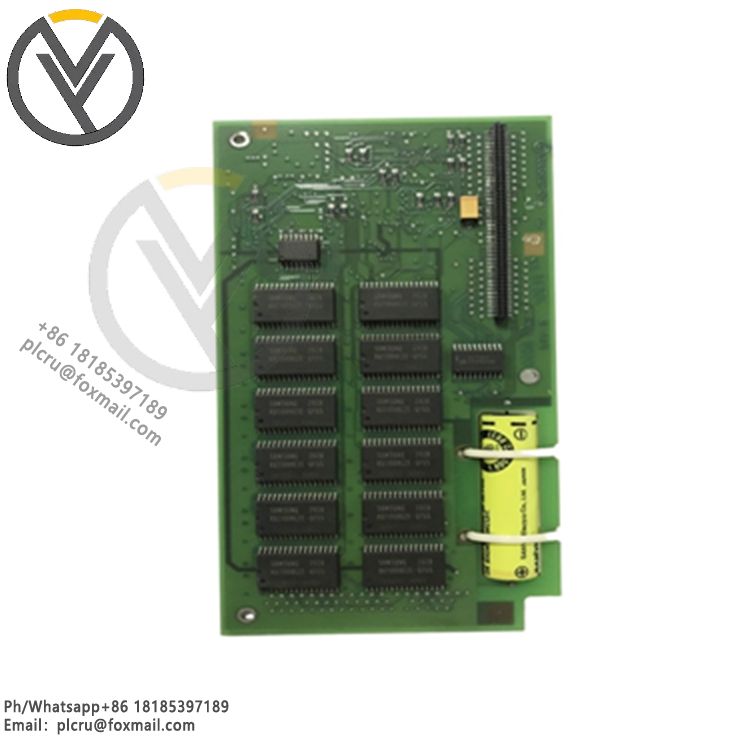

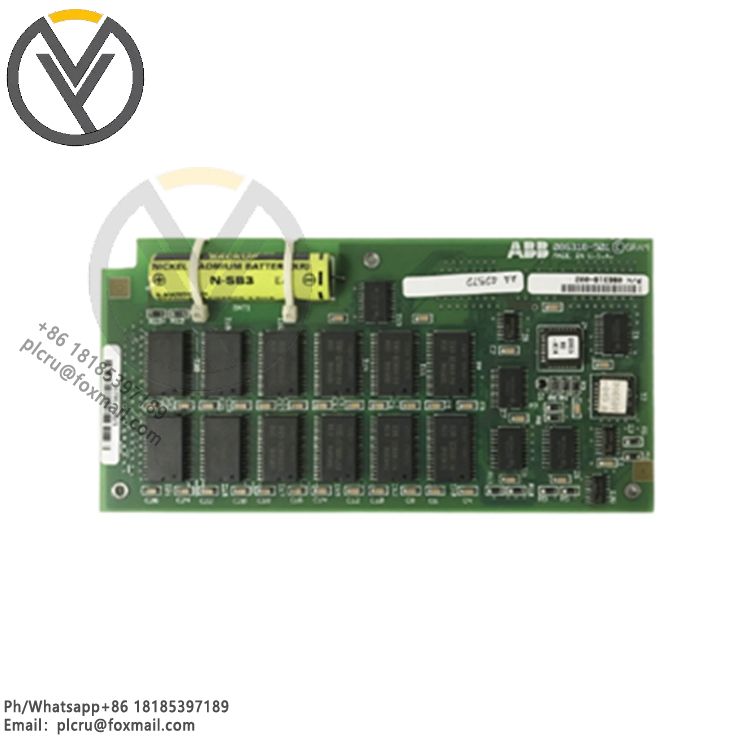

ABB 500CPU05 1MRB150081R0001 processor unit

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

The following is a detailed analysis of the ABB 500CPU05 1MRB150081R0001 process

The following is a detailed analysis of the ABB 500CPU05 1MRB150081R0001 processor unit, combined with the general characteristics of ABB industrial automation products and the technical logic of similar models:

I. Model analysis

Series positioning:

The 500 in 500CPU05 may correspond to ABB's AC500 series PLC (programmable logic controller), which is a mid-range controller launched by ABB, suitable for small and medium-sized automation systems and supports modular expansion.

CPU05 represents the performance level or version of the processor (such as basic type, enhanced type).

Model suffix:

1MRB150081R0001 is a unique product identification code used to distinguish hardware versions, configurations and production batches.

R0001 may indicate that the hardware revision is version 1.

II. Core functions and features

1. Processor performance

Central processing unit (CPU):

Adopts a high-performance 32-bit microprocessor to support tasks such as logic control, data processing, and communication protocol processing.

Processing speed: Refer to the typical indicators of the AC500 series (such as tens of thousands of instructions per second, depending on the model).

Memory configuration:

Integrated program memory (Flash ROM) and data memory (RAM) for storing user programs, variables and system parameters.

Supports expansion memory cards (such as SD cards) for program backup, firmware upgrades or data logging.

2. Communication capabilities

Built-in communication interface:

Usually includes Ethernet interface (supports PROFINET, EtherNet/IP or ABB custom protocol) for connecting to host computers, HMI or other controllers.

Serial interface (such as RS-232/RS-485), supporting industrial protocols such as MODBUS RTU and CANopen.

Distributed I/O support:

Distributed I/O modules can be connected via fieldbus (such as PROFIBUS, DeviceNet) to expand the system scale.

3. System expansion and compatibility

Modular architecture:

As the core unit of the AC500 series, it can be matched with digital/analog I/O modules, communication modules, function modules (such as counters, PID control), etc. to build a customized control system.

Compatibility:

Supports ABB's Control Builder PM5 programming software (based on IEC 61131-3 standard, supporting languages such as ladder diagrams and structured text).

Compatible with older AC500 modules, but pay attention to firmware version matching.

4. Reliability and protection

Industrial-grade design:

Adapt to a wide temperature range (such as -25°C ~ +60°C), resist vibration/shock, and comply with industrial environment standards (such as IEC 61131-2).

Fault diagnosis and redundancy:

Built-in self-diagnosis function, displaying operating status, communication failure, power supply abnormality, etc. through LED indicators.

Some models support hot standby redundancy (requires redundancy modules) to improve system reliability.