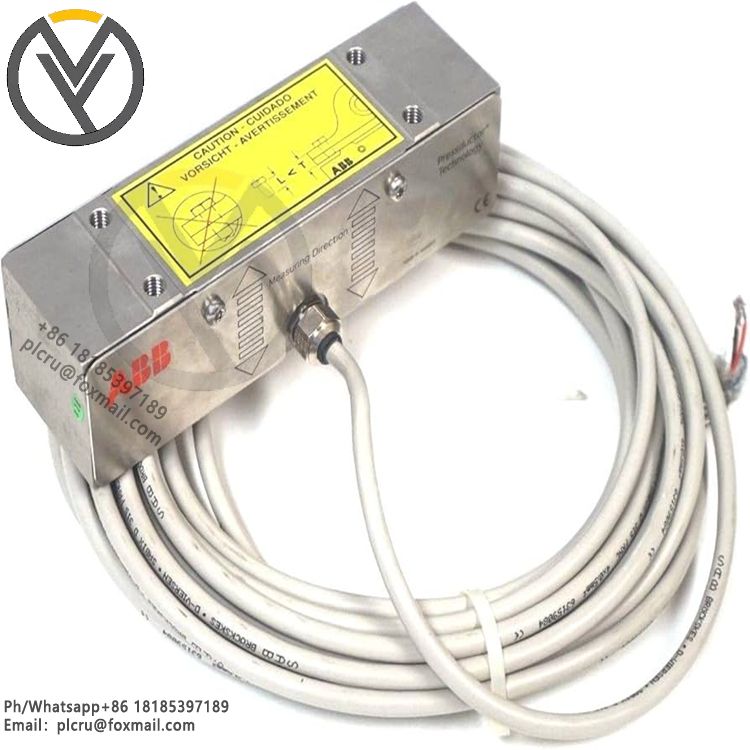

ABB 3HAC5566-1 Robot Controller Drive System Cable

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

ABB 3HAC5566-1 is a controller drive system cable designed for industrial robots

ABB 3HAC5566-1 is a controller drive system cable designed for industrial robots. It is used to connect the robot controller and the drive system (such as servo motors, drives, etc.), and undertakes the core functions of signal transmission and power supply. The following is a detailed analysis:

1. Product positioning and use

Core function:

Transmit control signals between the controller and the drive system (such as motor start and stop, speed command, position feedback, etc.).

Transmit power energy (such as the power supply of the servo motor) to ensure the stable operation of the drive system.

Application scenario:

Applicable to ABB's full range of industrial robots (such as IRB series), commonly used in automated production lines such as automobile manufacturing, electronic assembly, and logistics handling, especially in scenarios requiring high-precision motion control.

2. Technical characteristics

Electrical performance:

High anti-interference: The shielding design (such as twisted pair shielding or aluminum foil shielding) is adopted to effectively resist electromagnetic interference (EMI) in industrial environments and ensure the accuracy of signal transmission.

High voltage and high current resistance: Support the power supply transmission required by the drive system (such as three-phase AC power supply), and the wire cross-sectional area is adapted to the power requirements of the servo motor.

Signal transmission rate: Meet the real-time control requirements and can transmit high-speed pulse signals (such as encoder feedback signals).

Mechanical properties:

Bending and wear resistance: Highly flexible cable materials (such as PUR or PVC outer sheath) are used to withstand frequent bending and twisting during robot movement and adapt to dynamic movement scenarios (such as wiring at the joints of robot arms).

Protection level: Usually with IP65 protection (need to be combined with connector protection), dustproof and splashproof, suitable for humid and dusty industrial environments.

Temperature range: The operating temperature is generally -20°C ~ +80°C, suitable for high-temperature workshops or low-temperature working conditions.

Interface and compatibility:

Customized connector: Both ends are equipped with ABB standard interfaces (such as circular aviation plugs or rectangular connectors) to ensure accurate docking with controllers and drive modules.

Plug and play: The predefined pin assignment and protocol match the ABB robot system, without additional configuration, reducing the difficulty of installation and debugging.

3. Product Advantages

Reliability:

After ABB's rigorous industrial-grade tests (such as vibration tests and life cycle tests), it ensures long-term stable operation and reduces downtime caused by cable failures.

Adaptability:

Designed specifically for ABB IRC5 or OmniCore controllers, it is seamlessly compatible with drive systems (such as AX series servo drives) to avoid compatibility issues that may occur with third-party cables.

Easy to maintain:

Standardized cable layout and marking facilitate quick location of fault points; modular design supports rapid replacement and shortens maintenance cycles.

4. Common faults and maintenance

Fault types:

Signal interruption: It may be caused by loose connectors, damaged shielding layers, or broken wires, which manifests as motor loss of control or abnormal position feedback.

Power failure: Aging and short circuit of wires may trigger overcurrent protection or the motor cannot start.

Wear and damage: Long-term movement causes the outer sheath to crack or the internal wire to break. It is necessary to regularly check whether the cable bending radius meets the specifications.

Maintenance suggestions:

Regularly check the appearance of the cable, especially the wear of the joint movement parts.

Ensure that the connector is tight to prevent dust or oil from entering the interface.

When replacing cables, ABB original accessories must be used to avoid system compatibility risks caused by non-original cables.