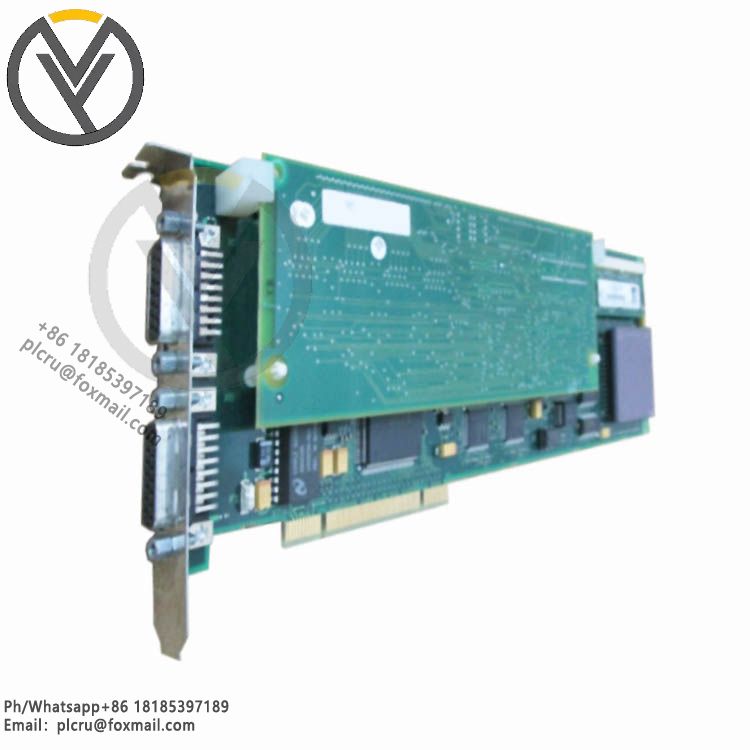

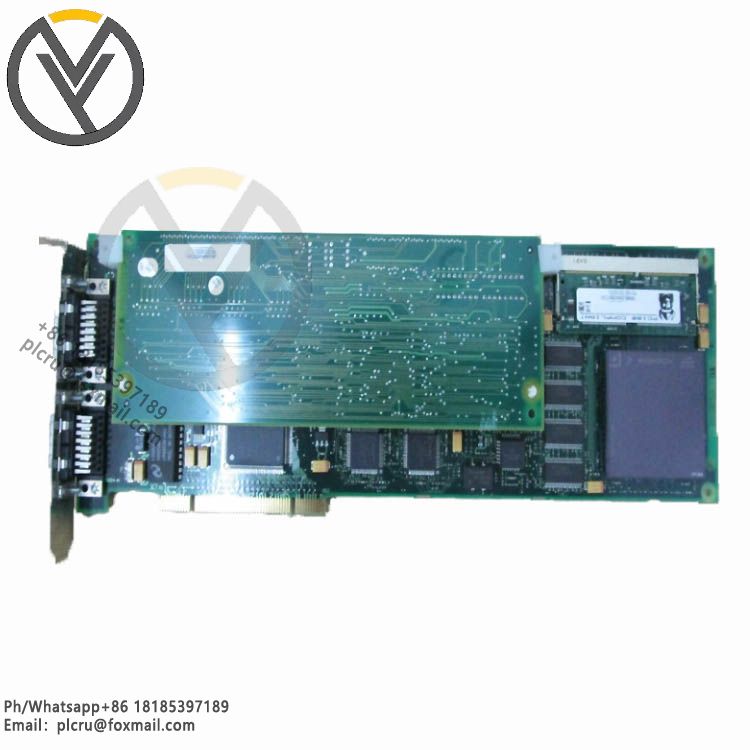

ABB PFXA401SF 3BSE050092R65 PFXA 401SF Control Unit Millmate Controller

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

ABB PFXA401SF 3BSE050092R65 is a high-performance control unit designed for roll

Product Overview

Application areas: Mainly used in rolling mill automation systems in industries such as steel and non-ferrous metals, which can accurately control key parameters such as thickness, flatness, tension, etc. during the rolling process.

Core functions: As the core of the Millmate control system, it integrates advanced algorithms and control strategies, supports real-time data processing, closed-loop control and equipment monitoring, and ensures efficient and stable operation of the rolling mill.

Technical parameters

Processor: Equipped with high-performance industrial-grade processors, supports multi-task parallel processing, and ensures real-time execution of complex control algorithms.

Memory: Large-capacity RAM and Flash memory, which can store program code, historical data and configuration parameters.

Communication interface:

Supports multiple industrial Ethernet protocols (such as Profinet, Ethernet/IP, Modbus TCP) to achieve high-speed communication with host computers, PLCs and other devices.

Equipped with RS485/RS232 interface, supporting serial communication protocols such as Modbus RTU.

I/O expansion: Supports expansion of digital and analog input and output through ABB standard I/O modules to meet the control needs of rolling mills of different sizes.

Working environment:

Working temperature: -20°C to + 60°C

Protection level: IP20 (needs to be installed in the control cabinet)

Anti-vibration and shock: meets industrial standards

Functional features

High-precision thickness control: Through real-time monitoring and adjustment of parameters such as roller pressure and speed, the thickness of the plate can be accurately controlled, and the tolerance can be controlled within a very small range.

Flatness optimization: Using advanced plate shape control algorithm, it automatically compensates for uneven deformation during rolling and improves the flatness of the plate.

Tension control: Accurately control the tension between the stands of the rolling mill to prevent the strip from running or breaking, and improve production efficiency and product quality.

Adaptive control: Automatically adjust the control parameters according to the characteristics of the rolled material and process requirements to achieve the best rolling effect.

Fault diagnosis and early warning: Built-in comprehensive fault detection system, real-time monitoring of equipment status, early warning of potential problems, and detailed fault diagnosis information.

Data recording and analysis: Support historical data storage and trend analysis, providing data support for process optimization and equipment maintenance.

Application scenarios

Cold rolling production line: used for thickness and flatness control of cold-rolled thin plates and strips.

Hot rolling production line: Realize coordinated control of temperature, pressure and speed during hot rolling.

Flattening machine: Improve the surface quality and flatness of the plate.

Stretch straightening machine: Control the tension and elongation of the strip and improve the plate shape.