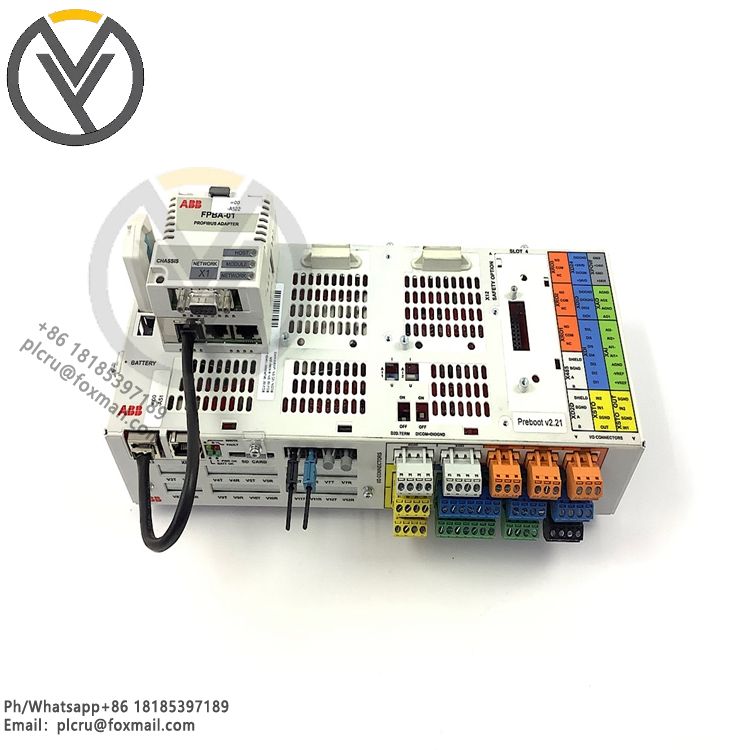

ABB TB521-ETH AC500 Terminal base

Delivery time 3 days

Product origin New/used

Email plcru@foxmail.com

Mobile/wechat /WhatsApp +86 18185397189

ABB TB521 - ETH AC500 Terminal Base is an Ethernet terminal base for ABB AC500 p

ABB TB521 - ETH AC500 Terminal Base is an Ethernet terminal base for ABB AC500 programmable logic controller (PLC) system. Here is its detailed introduction:

Functional features:

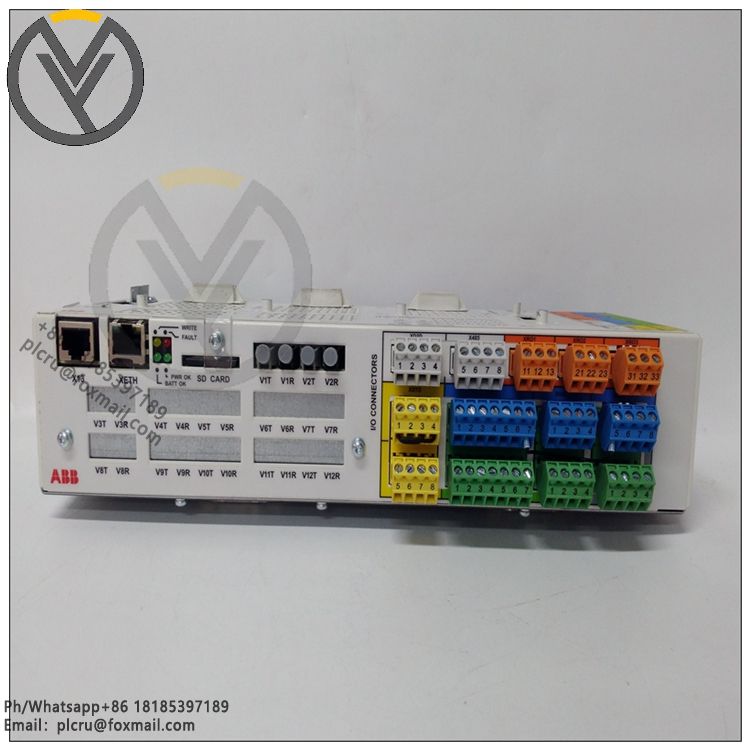

Powerful communication function: Provides communication capability for AC500 V2 PLC system, equipped with Ethernet interface, usually with two RJ45 connectors for Ethernet connection, convenient for high-speed data transmission with other devices, and realizes networking and remote monitoring between devices. At the same time, it has 2 serial interfaces (RS232/RS485), which can connect devices with corresponding interfaces, expand communication methods, and meet the communication needs of different devices.

Good scalability: There are 2 slots for communication modules, and different communication modules can be inserted according to specific application requirements to further expand its communication functions. For example, a wireless communication module can be inserted to realize wireless data transmission, or a specific protocol conversion module can be inserted to connect devices with different protocols.

Technical parameters:

Power supply requirements: Generally powered by 24V DC power supply, with a wide operating voltage range, usually 18 - 30V DC, can adapt to a certain degree of voltage fluctuations, and ensure stable operation under different power supply conditions.

Dimensions: The net depth/length of the product is 28 mm, the net height is 135 mm, and the net width is 123.5 mm. The size is compact and easy to install in a control cabinet with limited space.

Protection level: The protection level is IP67, with high dust and water resistance, and can be used in harsh industrial environments.

Application scenarios:

Industrial automation production line: used to connect AC500 PLC with various automation equipment, such as sensors, actuators, inverters, etc., to achieve collaborative work and automatic control between equipment, improve production efficiency and product quality.

Remote monitoring system: Connect the AC500 PLC system to the enterprise network or the Internet through the Ethernet interface to achieve remote monitoring and management of industrial equipment, so that engineers can obtain equipment operation status information anytime and anywhere, and perform remote fault diagnosis and maintenance.

Smart factory construction: As part of the Industrial Internet of Things (IIoT), the data of the underlying equipment is uploaded to the cloud or host computer system to provide data support for data analysis, optimization decision-making, etc. of smart factories, helping enterprises to achieve intelligent production and management.